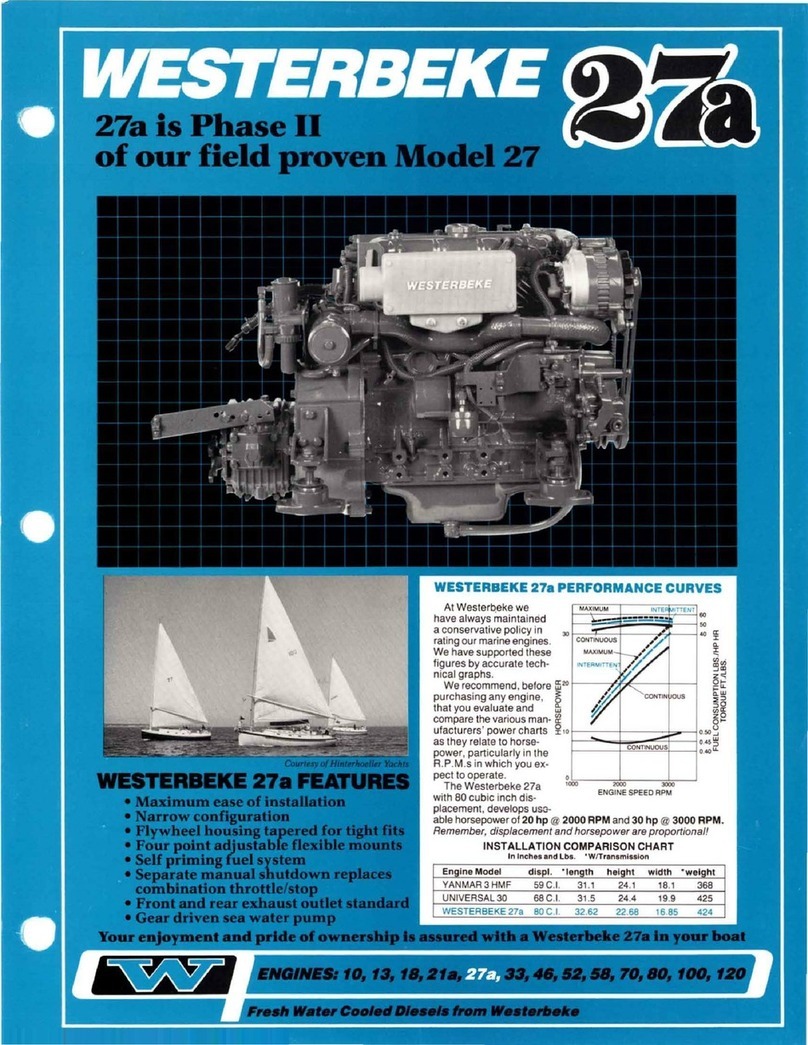

WESTERBEKE'S

NEW

58

HP,

FOUR CYLINDER,

MARINE

DIESEL

CONSTRUCTION

I. Cylinder Head: The special

cas

t·iron cylinder head

is

precision.

cas

t by the shell moulding process and then soft-gas-nitrided for

increased durability.The intakeand exhaust portsare arranged for

crossflow to raise

th

e intake and

~xhaust

efficiency.The

swirllype

precombustioll ch.llnher

is

used

.

2.

Cy

lind

er

Block: Weighl reduction achieved

by

technologies of

thin wall ductile

cas

t iron and half skirt. The water rail

is

designed

to pTovide uniform distribution of coolant to the cylinder head.

The cylinder liner

is

of the

dry

type of high-phosphorus c

ast

iron.

which

is

given special honing

10

pr

ovide

quick

sea

ling.

and

gnnd

nil

retention. thus

inneasing

we

ar

r

es

istan

ce.

:1

. Crank M

ec

hanism: The forged crankshaft

is

support

ed

by 5

bearings. The auto

th

crmatic piston of Lo·Ex alloy

has

a she

et

metal

cas

t in its skirt

so

as

to hold

th

e

th

ermal expansion of the piston.

thereby making it possible

to

lessen

the piston clearan

ce.

The pis-

ton pin

is

offset by 0.5mm. All

th

ese

improvements ensure quiet

operation from low

to

high sp

ee

d

s.

4. Valve M

ec

hanism: O.H.V. Both intake and exhaust valvesare of

rotation type for higher durability of

th

e

va

l

ve

seal.

Co

upl

ed

\

'I

.'i

lh

it

friction gear with one ext

ra

looth. the timing gear train isintended

to

el

iminate the backlash at the time of gear engagement to redu

('e

gear noise.

5.

Intake System: The intake manifold

is

of independent branch

type for higher intake efficiency.

6. Fuel System:The fuel injection pump

is

(I

Bosch VE type distrib-

ut

or

pump. small in

size

and light in weight. ('ontributing toward

noise reduction. Sin('c

fu

el can be cut with the solenoid valve built

in the pump.

th

e engineoperation can be stopp

ed

by turning off the

ignition switch.

SPECIFICATIONS

Numberof Cylinders & Arrangement

.....

4 in-line

Cy

linder Bore & Stroke

.......

_. . . .3.5 in. x 4 in.

Displa

ce

ment

....

..........

.

154

in.

Compression Ratio . . . . . . . . . . . . . . .

......

21.0

Co

mbustion Chamber . . . . . . . • . . . . . . . . . . . . .

wirl

Typ

e

FiringOrder

............•.........................

1-3·4·2

Injection Pump

.............•.

.

.......

Bos

ch DistributorType

Governor

..............

. . .

.......

M

ec

hanical (Built in Pump)

Lubricalion Method . . . . . . . . . . . . . .

....

Pressure Feed Type

CoolingMethod . . . . . . . . . . . . . . .

...

Fresh Water Cool

ed

Auxiliary

Starter . . . . . . . . . .

.......

•........

....

Glow Plug

Electri

ca

l System Voltage

....

.

................

12

Volts

Dry Weight of Engine (w/Trans

.)

...............

692lbs.

PowerTake

-o

ff

..

...........

..

VariousCrankshaft Pulleys

PERFORMANCE

CURVE

~

CON;;~;;~

J t I

PERFORMANCE

DATA

Maximum

Torque

..

...................

117.9Ib.ft

J2

200

r.pm.

One H

our

Rated Power Output

......

44.8

HP

/2

000

r.p.m.,

55.2

HP

/2

500

r.pIn

.,

62

HP

/3

000

r.pm

.

Continuous Rated Power Output

...

...

38

HP

/2

000

r.p.m.,

46.9

HP

/2500

r.p.m.,

52.8

HP

/3

000

r.p.m.

Maximum PowerOutput

....................

69

HP

/3

600

r.pm.

Typical Fuel Consumption

Rate

...............

063

US

gal/HP/hr

Typical

Fuel Consumption

Rate

at

2500

RPM

when wheeled to

tum

3000

RPM

...............

1

.9

US

gal/hr

Capacity of Lubricant(sump)

..........

.........

......

6.3

qt.

Capacity of Coolant (engine

only

)

.....................

10.5

qt.

Performance is based

on

JIS

standard atmospheric

condition

(atmosp

heric pressure 760mm

Hg,

temp

20

C,

humidity

65

'\,)

without

cooling

fan.

STANDARD

EQUIPMENT

Alarm

,

low

oil

pressure. high water temperature (

Clutch and

2:1

Reduction Gear (

R.H.

Propeller)

Adjustable flex isolatorengine mounts(18

··

on centre)

Fresh

water

coo

ling system

Coolant Recovery Tank

12

volt

55

ampere alternator

Throttle,

and s

hift

control brackets

Glow plug cold weather starting aid

Engine

pre-wired

at the factory

with

a single 8

pin

co

nn

ector

Operators

manual

Water Injected Exhaust Elbow

Lube Oil Drain Ho

se

Flowcontroller-for

easy connection of domestic

hot

water heater

OPTIONAL

EQUIPME T

Remote

mounting

lube

oil

filter

Various accessory front pulleys

Hydro-Hush Muffler

Sea

WaterStrainer

Alternator

Output Splitter

Five

Function

Electric Instrument Panel including

Hour

Meter

and

Tachometer

A wide

variety

of

Manual and Hydraulic Transmissions are

available

in

various Reduction Gears and

Vee

Drives.

Front

exhaust

outlet

for vee drive applications

Primary

90 amp.

alternator

18/20/22-1/2" Mounting

ce

nt

e

rs

CALL

YOUR WESTERBEKE REPRESENTATIVE

[ 1

OR

CONTACT

THE

...

J. H.

WESTERBEKE

CORP.

Manne NLP

6/82

7,500PTlrlled

11'1

USA

Avon

Indu

strial Park,

Avon

,

MA

02322,

(617)

588

·

7700

Cable

:

Westcorp,

Avon,

Telex:

92·4444