INTRODUCTION

SERIAL

NUMBER

LOCATION

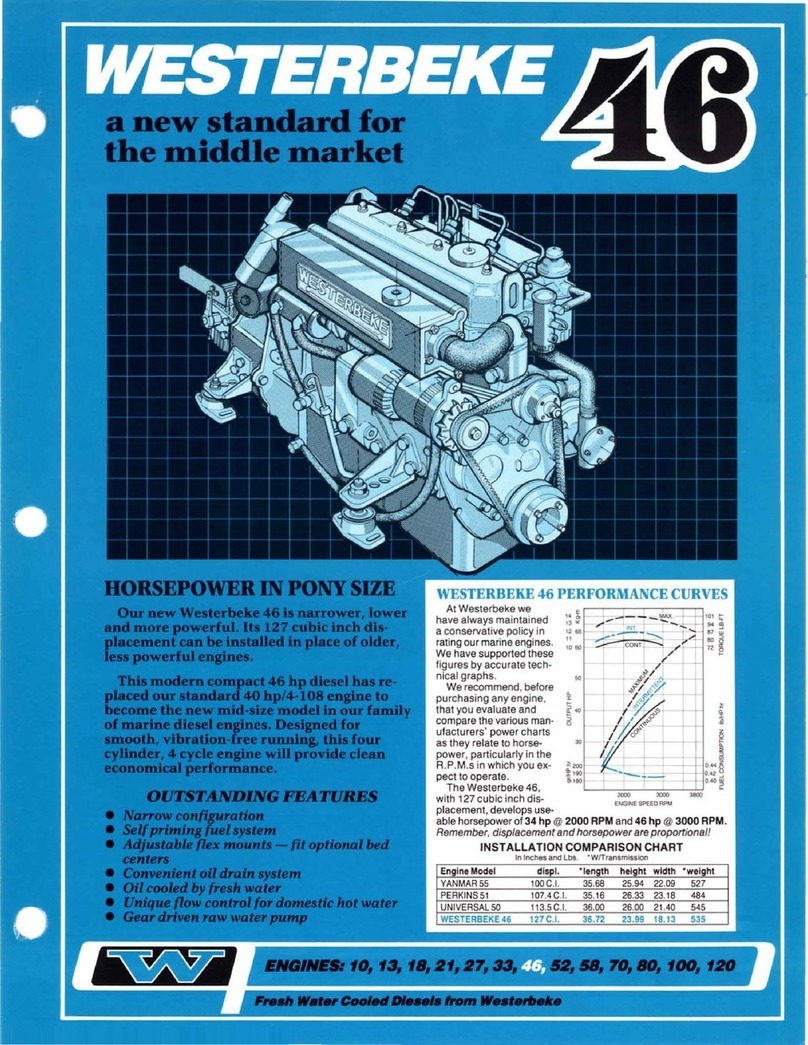

The engine's model designation and serial number are

located

on

a nameplate that is mounted on the side

of

the

waterjacketed exhaust manifold. The engine's serial number

can also be found stamped into the fiat block surface located

just

above the manual shut-offlever. Take the time to enter

this information

on

the illustration

of

the name plate shown

below, as this will provide a quick reference when seeking

technical information and/or ordering parts.

~2£ii#;l=143=t

0 . . 0

•

MODEL

SPEC

AVO•

"'"USA

SER.NO.

•

UNDERSTANDING

THE

DIESEL

ENGINE

The diesel engine closely resembles the gasoline engine,

since the mechanism is essentially the same. The cylinders

are arranged above a closed crankcase. The crankshaft is the

same general type as a gasoline engine, and the diesel engine

has the same type

of

valves, camshaft, pistons, connecting

rods and lubricating system.

Therefore, to a great extent, a diesel engine requires the same

preventive maintenance as a gasoline engine. The most

important factors are proper ventilation and proper mainte-

nance

of

the fuel, lubricating and cooling systems. Fuel and

lubricating filter elements must be replaced at the time peri-

ods specified, and frequent checking for contaminants (water,

sediment, etc.) in the fuel system is also essential. Another

important factor is the consistent use

of

the same brand

of

high detergent diesel lubrication oil designed specifically for

diesel engines.

The diesel engine does differ from the gasoline engine,

however, in its method

of

handling and firing

of

fuel. The

carburetor and ignition systems are replaced by a single

component -the fuel injection pump -which performs the

function

of

both.

CARBON

MONOXIDE

DETECTOR

WESTERBEKE recommends mounting a carbon monoxide

detector in the vessels living quarters.

Carbon

monoxide,

even

in

small amounts, is deadly. ·

The presence

of

carbon monoxide indicated an exhaust leak

from the engine or generator

or

from the exhaust

elbow/exhaust hose,

or

the fumes from a nearby vessel are

entering your boat.

If

carbon monoxide is present, ventilate the area with clean

air and correct the problem immediately!

ORDERING

PARTS

Whenever replacement parts are needed, always provide the

engine model number and serial number as they appear on

the silver and black nameplate located on the manifold. You

must provide us with this information so we may properly

identify your engine. In addition, include a complete part

description and part number for each part needed (see the

separately furnished Parts List). Insist upon WESTERBEKE

packaged parts because willfit

or

generic parts are frequently

not made to the same specifications as original equipment.

SPARES

AND

ACCESSORIES

Certain spares will

be

needed to support and maintain your

WESTERBEKE engine. Your local WESTERBEKE dealer

will assist you in preparing an inventory

of

spare parts. See

the

SPARE

PARTS

page in this manual. For engine acces-

sories, see WESTERBEKE's ACCESSORIES brochure.

INSTALLATION

MANUAL

Publication #43400 provides detailed infoimation for

installing generators.

Engines & Generators

4