WD-Series Coils

4

comply with specifications requiring Residual or Active Fields.

AC Option is designed to convert the Output Field from DC to AC. When configured to

operate in AC Mode, the output of the coil is a minimum of 4000-Ampere Turns, but is size

and input voltage dependent. The AC Option is only available where coils have been

specifically manufactured with is capability.

Pulsed DC Option is activated with a switch on the Control Panel, immediately next to the

Energize Button. When activated, the Coil automatically begins to Pulse at a rate of

approximately 80 times per minute. The Amp Meter does not display the amperage while in

Pulse Mode. The duty cycle, when in Pulsed Mode, is extended to 100% as the Coil is

energized less that 30% of the time. Thus, while is Pulse Mode, the unit can be left on for

extended periods of time. While in Pulsed Mode, all other functions continue to operate

(Variable Amperage, and Reversible Polarity), but are typically not required during testing.

The Pulsed Option truly gives the operator the ability to perform an Active Field Inspection.

The Pulses occur about every ¾ of a second, with a very short duration. This way, the

particles are ‘jarred’ every pulse, to give the particles that encouragement they need to

congregate around cracks. Performing an Active Field Inspection with Pulsed DC will not

just satisfy an auditor looking over the inspector’s shoulder, but will actually help to produce

faster and crisper indications.

DO NOT CHANGE THE POLARITY WHEN THE PULSE SWITCH IS TURNED ON.

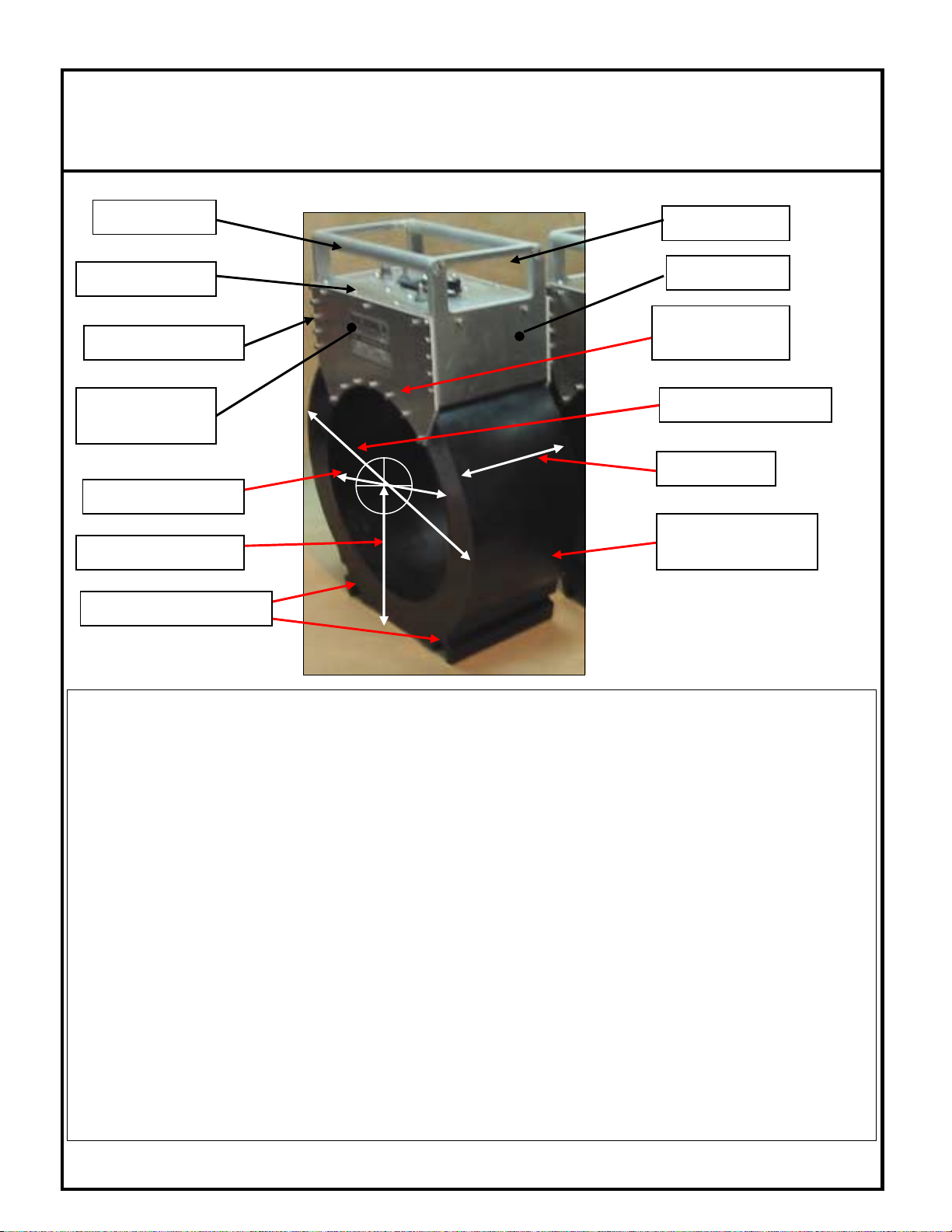

5. Operation

The Coil is either placed on the Work Piece, such as a threaded end of a pipe, or if the Work

Piece is small it can be held within the inside of the coil. If held and if it is short enough to

be rotated within the coil, a longitudinal or transverse field can be induced into the Work

Piece. Application of particles, depending on the specification and skill of the operator, are

applied during (Active Field) or after the field is set-up in the Work Piece (Residual Field).

Active Field Inspection requires less skill by the operator in the application of the particles,

while in Residual Field Inspection there is no particle migration and greater skill and care

must be taken in media application.

WDV Models are placed over the Work Piece, setting of the Field Intensity by the operator

with the Current Control Knob, and followed by energizing the coil (a “Shot”) with the Push

Button Energizing Switch. A positive or negative field is induced, followed by an Active or

Residual Field Inspection.

To Demagnetize the Work Piece;

1. The operator places the coil back over the work piece and reduces the Current Control

Knob by approximately 20% from the magnetization current selection.

2. The operator must then reverse the field to the opposite polarity (direction) from the

magnetization shot.

3. The operator then presses the Energize Button for a short duration.

4. The Current Control Knob is again reduced by approximately 20%, the field is reversed,

and then the coil is again Energized for a short duration.

5. Steps 1 through 3 are repeated until the final shot at 0 amps.

Note: Contact Western Instruments for more complete Demagnetization information.