I02-243 User & maintenance manual Version 03 (translation of the original manual)

of TLM1500 ITS 24 V

Table of contents

1 General information.........................................................................................................................1

1.1 Important notice ..................................................................................................................... 1

1.2 Applicable standards............................................................................................................... 1

1.3 Applications ............................................................................................................................ 1

1.4 Terms of use............................................................................................................................ 1

1.5 Security instructions................................................................................................................ 2

1.6 Motor’s safety instructions ..................................................................................................... 2

1.7 Additional information............................................................................................................ 3

2 Technical caracteristics ....................................................................................................................3

3 Commisionning.................................................................................................................................4

3.1 Receipt of equipment.............................................................................................................. 4

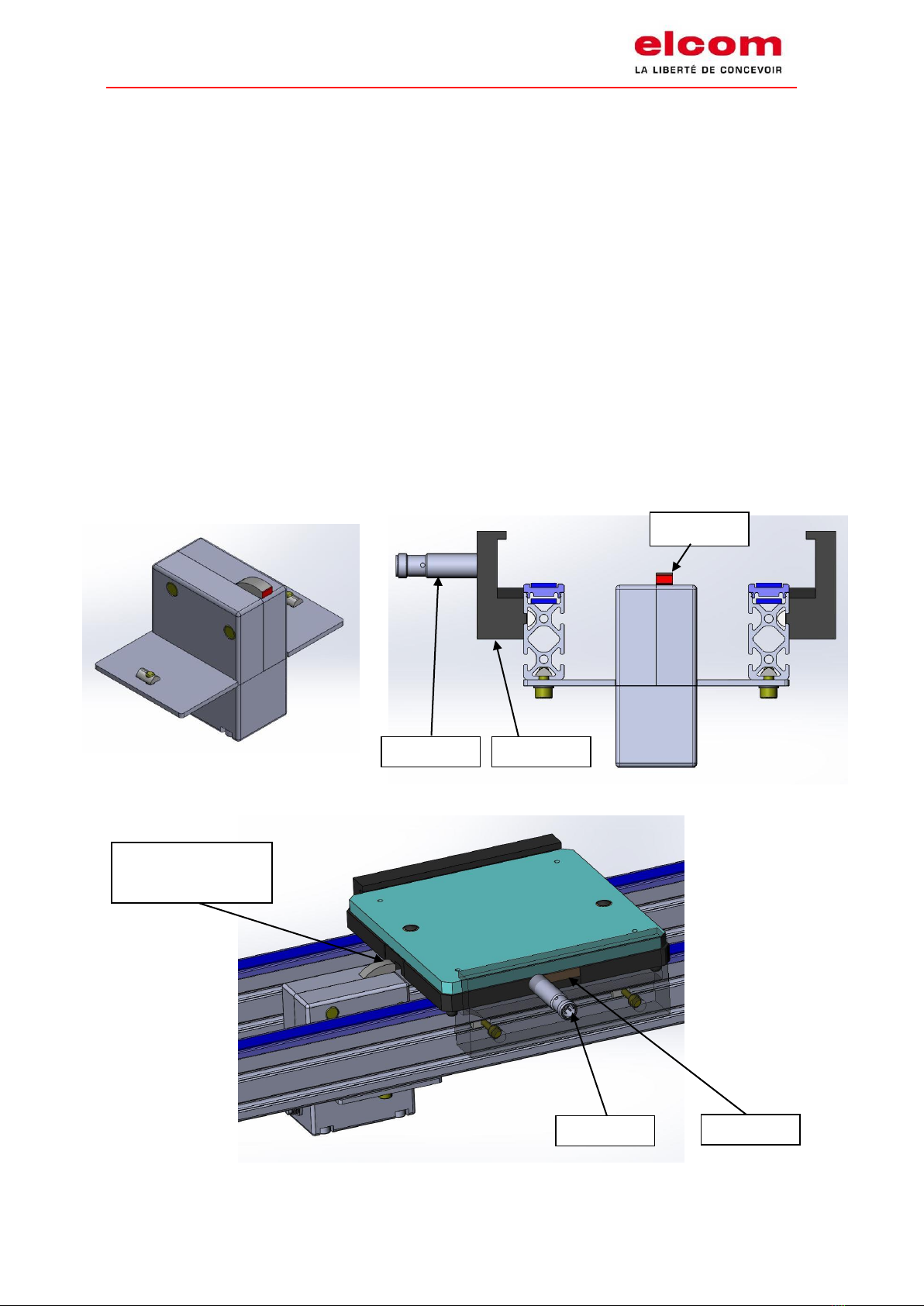

3.2 Stopper.................................................................................................................................... 4

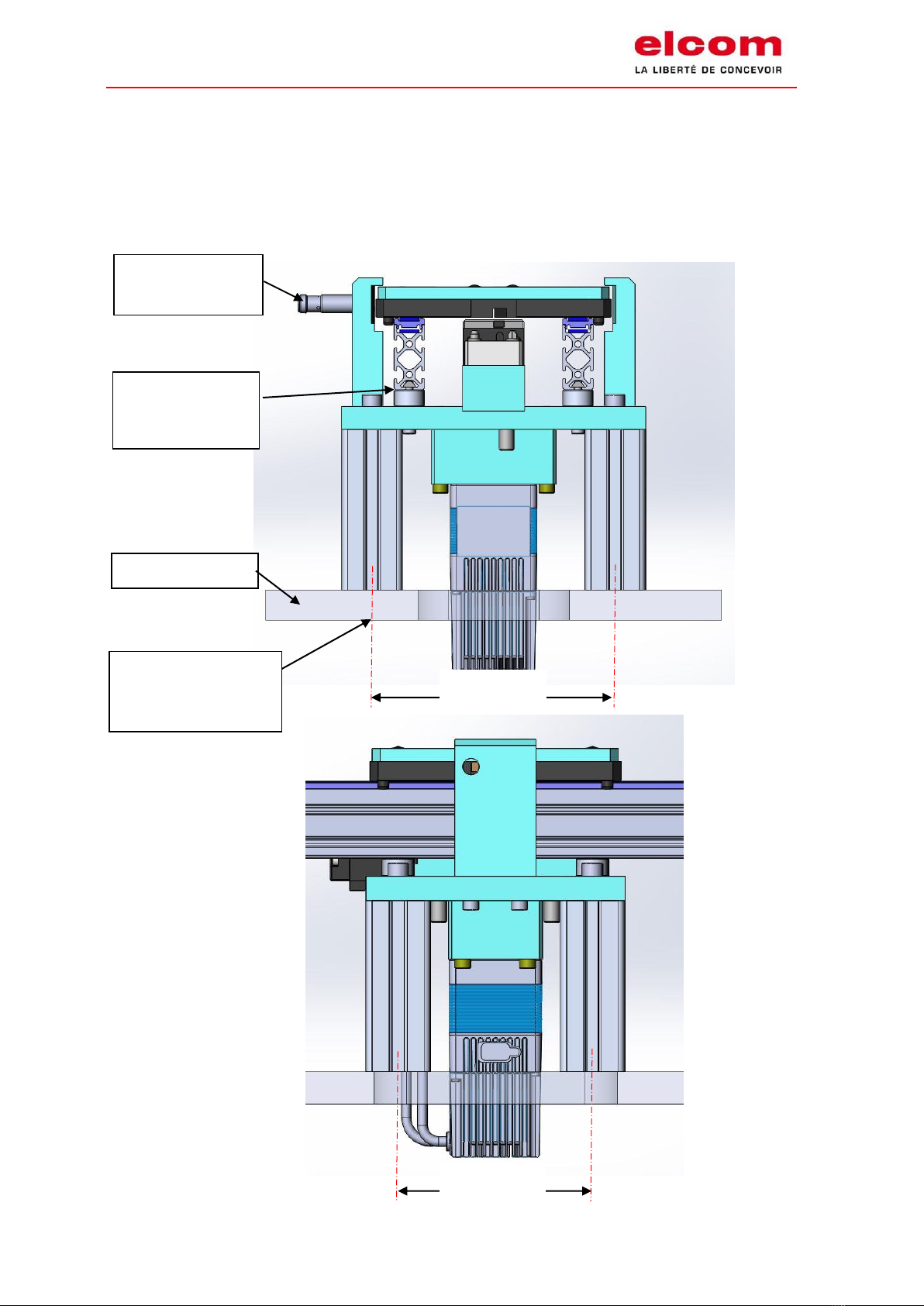

3.3 Positioning unit........................................................................................................................ 5

3.4 Double cam.............................................................................................................................. 6

3.5 Derivation................................................................................................................................ 7

3.6 Carrier...................................................................................................................................... 8

4 Maintenance ....................................................................................................................................9

4.1 Belts wear................................................................................................................................ 9

4.2 Passageways of workpiece carriers......................................................................................... 9

4.3 Pins .......................................................................................................................................... 9

4.4 Wear of the belt guide ............................................................................................................ 9

4.5 Transfert parts....................................................................................................................... 10

4.6 Stoppers ................................................................................................................................ 10

4.7 Positioning unit...................................................................................................................... 11

4.8 Double cam............................................................................................................................ 12

4.9 Derivation.............................................................................................................................. 12

4.10 Other elements of the transfert............................................................................................ 12

5 Changeout of the 24V drive motor ............................................................................................... 13

5.1 Unit with PAPST drive motor:................................................................................................ 13

5.2 Unit with CROUZET motor drive :.......................................................................................... 16

6 Changeout of the drive motor of index unit 24v........................................................................... 19

7 Changeout the toothed belt.......................................................................................................... 21

8 wiring the 24v drives motors......................................................................................................... 22

8.1 Unit with PAPST drive motor :............................................................................................... 22

8.2 Unité avec moteur CROUZET :............................................................................................... 23