PAGE 2

TT

TT

Table of Contentsable of Contents

able of Contentsable of Contents

able of Contents

Section 1 - GeneralSection 1 - General

Section 1 - GeneralSection 1 - General

Section 1 - General ....................................................................................3....................................................................................3

....................................................................................3....................................................................................3

....................................................................................3

1.1 MOUNTING ................................................................................................31.1 MOUNTING ................................................................................................3

1.1 MOUNTING ................................................................................................31.1 MOUNTING ................................................................................................3

1.1 MOUNTING ................................................................................................3

1.2 WETTED MATERIALS .....................................................................................31.2 WETTED MATERIALS .....................................................................................3

1.2 WETTED MATERIALS .....................................................................................31.2 WETTED MATERIALS .....................................................................................3

1.2 WETTED MATERIALS .....................................................................................3

1.3 OPERATING PRECAUTIONS ............................................................................31.3 OPERATING PRECAUTIONS ............................................................................3

1.3 OPERATING PRECAUTIONS ............................................................................31.3 OPERATING PRECAUTIONS ............................................................................3

1.3 OPERATING PRECAUTIONS ............................................................................3

Section 2 - SpecificationsSection 2 - Specifications

Section 2 - SpecificationsSection 2 - Specifications

Section 2 - Specifications ......................................................................................3.............................3

.............................3.............................3

.............................3

Section 3 - Location RequirementsSection 3 - Location Requirements

Section 3 - Location RequirementsSection 3 - Location Requirements

Section 3 - Location Requirements .......................................................3.......................................................3

.......................................................3.......................................................3

.......................................................3

Section 4 - Sanitary MountingSection 4 - Sanitary Mounting

Section 4 - Sanitary MountingSection 4 - Sanitary Mounting

Section 4 - Sanitary Mounting ...............................................................4...............................................................4

...............................................................4...............................................................4

...............................................................4

Section 5 - Sensor/ Interconnect Cable TSection 5 - Sensor/ Interconnect Cable T

Section 5 - Sensor/ Interconnect Cable TSection 5 - Sensor/ Interconnect Cable T

Section 5 - Sensor/ Interconnect Cable Terminationermination

erminationermination

ermination ........................6........................6

........................6........................6

........................6

5.1 SENSOR CABLE DETAILS5.1 SENSOR CABLE DETAILS

5.1 SENSOR CABLE DETAILS5.1 SENSOR CABLE DETAILS

5.1 SENSOR CABLE DETAILS ........................................................................6........................................................................6

........................................................................6........................................................................6

........................................................................6

5.2 CE TERMINA5.2 CE TERMINA

5.2 CE TERMINA5.2 CE TERMINA

5.2 CE TERMINATION PROCEDURE (FOR CE-TION PROCEDURE (FOR CE-

TION PROCEDURE (FOR CE-TION PROCEDURE (FOR CE-

TION PROCEDURE (FOR CE-ONLONL

ONLONL

ONLY APPLICAY APPLICA

Y APPLICAY APPLICA

Y APPLICATIONS) .............................7TIONS) .............................7

TIONS) .............................7TIONS) .............................7

TIONS) .............................7

5.3 STANDARD TERMINATION PROCEDURE (EXCEPT CE) ..........................................85.3 STANDARD TERMINATION PROCEDURE (EXCEPT CE) ..........................................8

5.3 STANDARD TERMINATION PROCEDURE (EXCEPT CE) ..........................................85.3 STANDARD TERMINATION PROCEDURE (EXCEPT CE) ..........................................8

5.3 STANDARD TERMINATION PROCEDURE (EXCEPT CE) ..........................................8

5.4 INTERCONNECT CABLE DETAILS........................................................................95.4 INTERCONNECT CABLE DETAILS........................................................................9

5.4 INTERCONNECT CABLE DETAILS........................................................................95.4 INTERCONNECT CABLE DETAILS........................................................................9

5.4 INTERCONNECT CABLE DETAILS........................................................................9

Section 6 - TSection 6 - T

Section 6 - TSection 6 - T

Section 6 - Troubleshootingroubleshooting

roubleshootingroubleshooting

roubleshooting ...................................................................10...................................................................10

...................................................................10...................................................................10

...................................................................10

6.1 CHECKING THE SENSOR ...............................................................................106.1 CHECKING THE SENSOR ...............................................................................10

6.1 CHECKING THE SENSOR ...............................................................................106.1 CHECKING THE SENSOR ...............................................................................10

6.1 CHECKING THE SENSOR ...............................................................................10

Section 7 - Ordering MatrixSection 7 - Ordering Matrix

Section 7 - Ordering MatrixSection 7 - Ordering Matrix

Section 7 - Ordering Matrix ..................................................................10..................................................................10

..................................................................10..................................................................10

..................................................................10

Section 8 - WSection 8 - W

Section 8 - WSection 8 - W

Section 8 - Warranty and Rarranty and R

arranty and Rarranty and R

arranty and Return Statementeturn Statement

eturn Statementeturn Statement

eturn Statement .....................................11.....................................11

.....................................11.....................................11

.....................................11

FIGURESFIGURES

FIGURESFIGURES

FIGURES

FIGURE 4-1FIGURE 4-1

FIGURE 4-1FIGURE 4-1

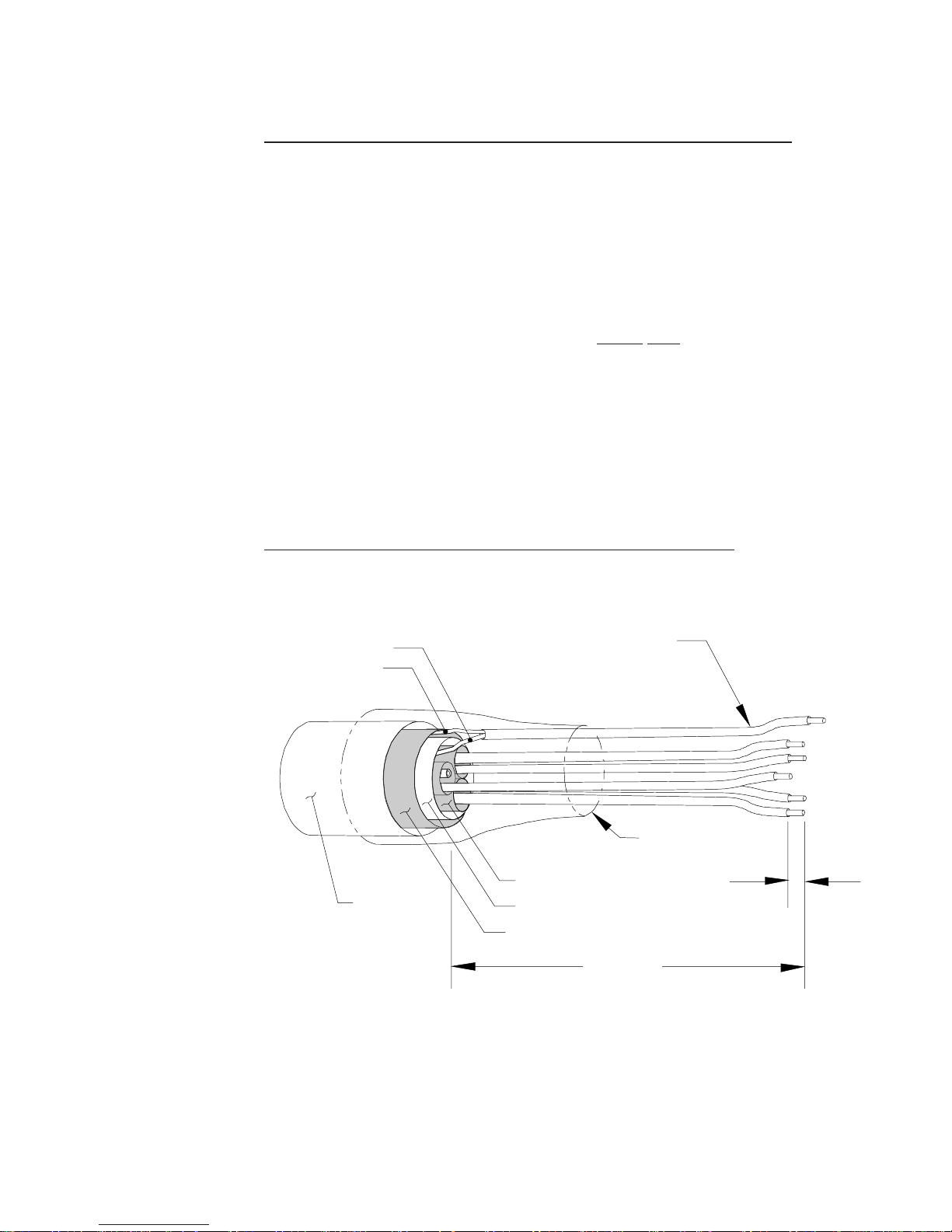

FIGURE 4-1 SANITARY MOUNTING DETAILS ....................................................5SANITARY MOUNTING DETAILS ....................................................5

SANITARY MOUNTING DETAILS ....................................................5SANITARY MOUNTING DETAILS ....................................................5

SANITARY MOUNTING DETAILS ....................................................5

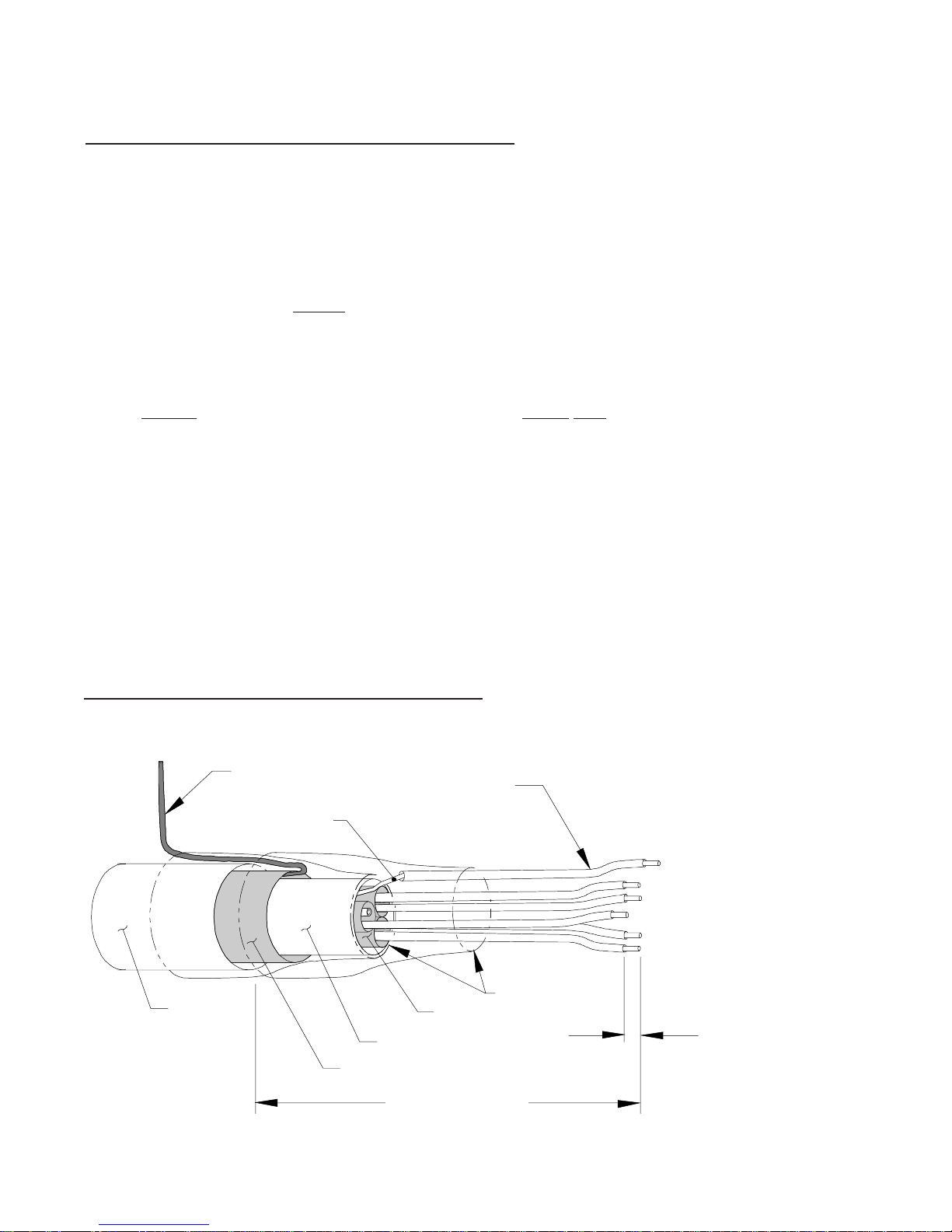

FIGURE 5-1FIGURE 5-1

FIGURE 5-1FIGURE 5-1

FIGURE 5-1 STANDARD TERMINATION DETAILSSTANDARD TERMINATION DETAILS

STANDARD TERMINATION DETAILSSTANDARD TERMINATION DETAILS

STANDARD TERMINATION DETAILS (EXCEPT CE)................................7(EXCEPT CE)................................7

(EXCEPT CE)................................7(EXCEPT CE)................................7

(EXCEPT CE)................................7

FIGUREFIGURE

FIGUREFIGURE

FIGURE 5-25-2

5-25-2

5-2 CE TERMINACE TERMINA

CE TERMINACE TERMINA

CE TERMINATION DETTION DET

TION DETTION DET

TION DETAILS (FOR CE-AILS (FOR CE-

AILS (FOR CE-AILS (FOR CE-

AILS (FOR CE-ONLONL

ONLONL

ONLY APPLICAY APPLICA

Y APPLICAY APPLICA

Y APPLICATIONS) .................8TIONS) .................8

TIONS) .................8TIONS) .................8

TIONS) .................8

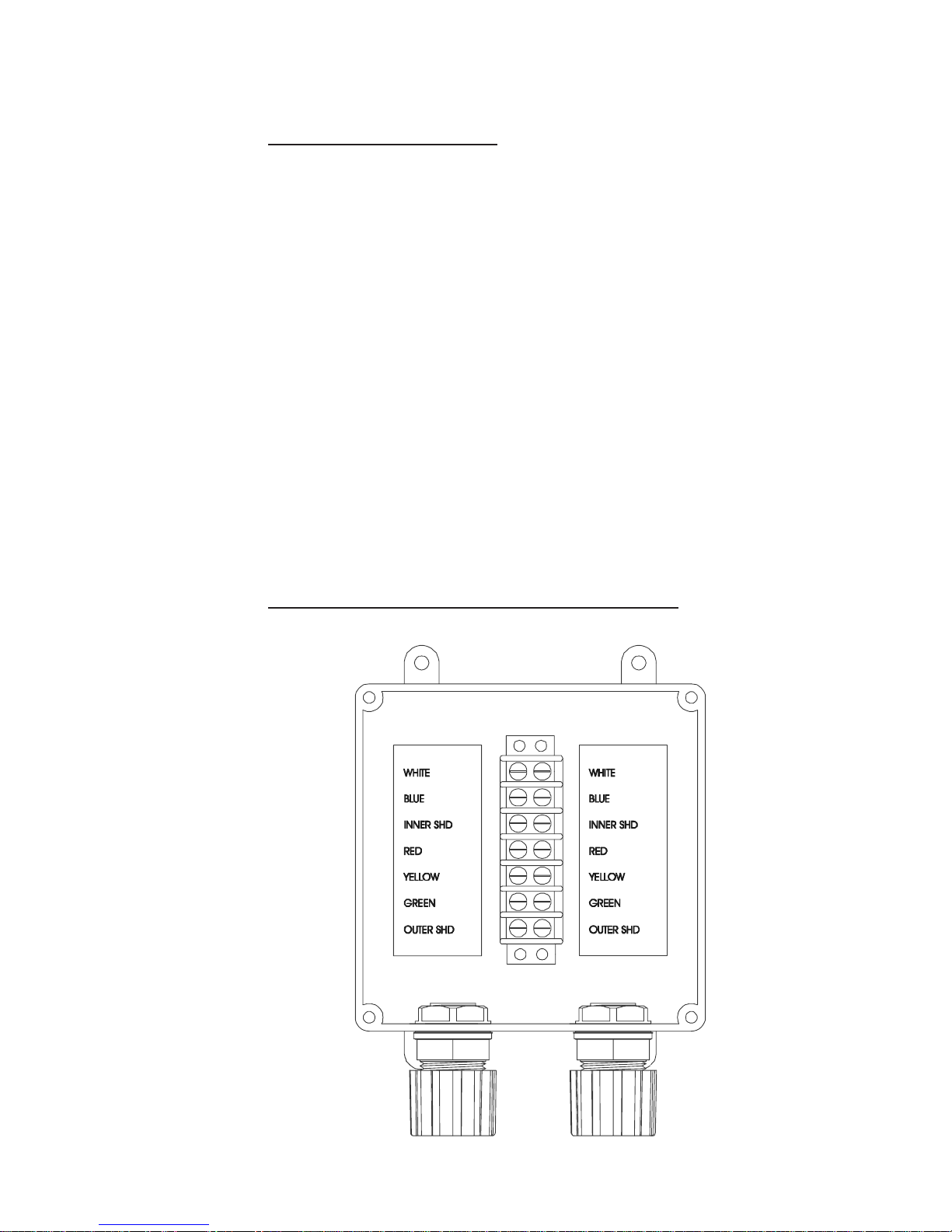

FIGURE 5-3FIGURE 5-3

FIGURE 5-3FIGURE 5-3

FIGURE 5-3 INTERCONNECT CABLE / JUNCTION BOX TERMINATIONS ...................9INTERCONNECT CABLE / JUNCTION BOX TERMINATIONS ...................9

INTERCONNECT CABLE / JUNCTION BOX TERMINATIONS ...................9INTERCONNECT CABLE / JUNCTION BOX TERMINATIONS ...................9

INTERCONNECT CABLE / JUNCTION BOX TERMINATIONS ...................9