Page 8 of 14VCIOM-04592

DEPIC 2 HART POSITION TRANSMITTER - MODELS D510 AND D520

INSTALLATION AND OPERATIONS MANUAL

5.10 The following setting is dependent on the

pressure sensor-2 configuration. If the

user has disabled the pressure sensor-2

in the previous step, the DEPIC-2 will skip

this step otherwise the LCD will display

the following screen to configure the

DEPIC-2 for the pressure sensor-2 usage.

Use the up/down arrow key to change the

selection between “Supply Pressure” and

“Actuator Chamber Pressure”. Press the

Select key to accept the current selection.

Supply

Pressure:The DEPIC-2 will assume the

pressure sensor-2 is pneumatically

connected to monitor the supply

pressure. It will show all pressure-2

related hysteresis and alarm settings

in the full menu later on to monitor

the supply pressure. The user must

have purchased a DEPIC-2 model

that has the pressure sensor-2.

Actuator

Pressure:

The DEPIC-2 will assume the

pressure sensor-2 is pneumatically

connected to monitor the second

chamber of the actuator. It will show

all pressure-2 related hysteresis

and alarm settings in the full menu

later on to monitor the pressure in

the second actuator chamber. The

user must have purchased a DEPIC-2

model that has the pressure sensor-2.

Press-2 Use10/13

------------------

5.11

This step is dependent on the current

clock configuration. If the DEPIC-2 has the

valid time preconfigured from the factory,

it might skip this step to configure the

clock otherwise it will display the following

screen to configure the clock on the device.

Use the up/down arrow key and the select

key to configure the date and time. The

date must be configured in Month/Day/Year

format and the time must be configured in

Hours: Minutes in 24 hours format.

Clock Setup11/13

------------------

Set time in 24hr

5.12 This step is dependent on the setting

“Device Control” configured in the

previous step. If the user has disabled the

“Device Control” in the previous step, the

DEPIC-2 will display the screen to run the

manual calibration. If the user has enabled

the “Device Control” setting in the previous

step, the DEPIC- 2 will display screen to

run the auto calibration. Use the up/down

arrow key to change the selection between

“Yes” and “No”. Press the Select key to

accept the current selection.

NOTE

If ‘AUTO CALIBRATION’ has been selected, please

ensure that the correct pneumatic (see Section 3.1

and 3.2)/ electrical connections (see Figure 4.1) have

been made and are turned on and the solenoid voltage

connections have been made.

Auto Cal 12/13

------------------

This will move valve &

erase Baseline PST &

FST Data.

Continue?

No

6 USER INTERFACE

6.1 The DEPIC2 position transmitter has both

an on-board keypad/LCD menu structure

and/or a HART menu structure that can be

accessed by pressing the Select button or

from the Main Menu of a HART host. Exit

any function by pressing the up arrow

button to back out of any keypad menu or

the back arrow on the 475.

6.2 The basis of the menu systems of the

DEPIC2 were developed with a HART DD

and are emulated by the Push Button/

LCD menu system so once someone

gets used to using one interface, it

becomes easy to navigate the other

interface. See the following sections on

Configuring and Calibrating the DEPIC2.

While the menus shown below more closely

illustrate the Push Button/LCD, the HART

DD menus are very similar if not identical.

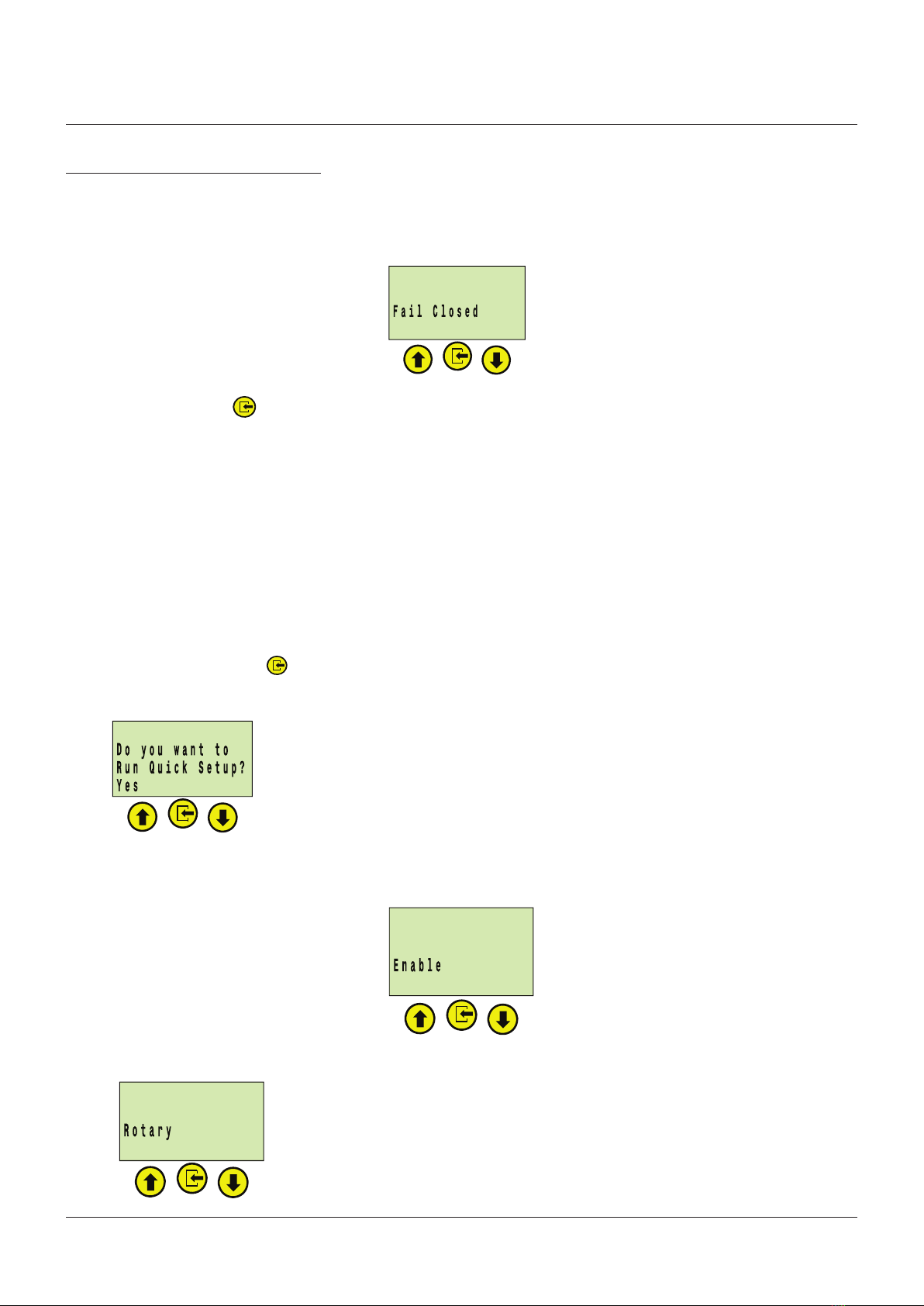

6.3 From the keypad/LCD interface, if the

device is not configured when first powered

up, it will ask the user to run the setup

wizard when the user tries to access the

menu screen. If the user selects to run

the setup wizard, it will ask the user to

configure some basic settings step by step

and perform the calibration. The setup

wizard is only available using keypad/LCD

not on the HART DD.

Copyright © Crane Co. All rights reserved