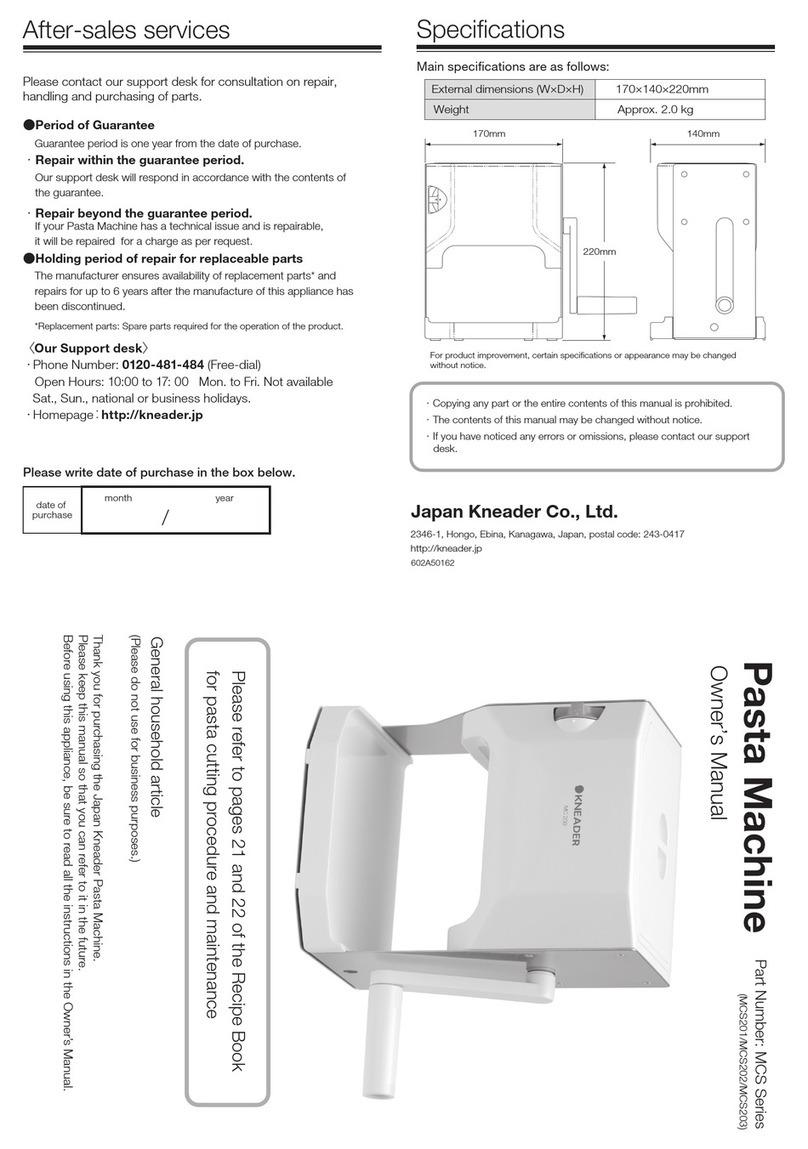

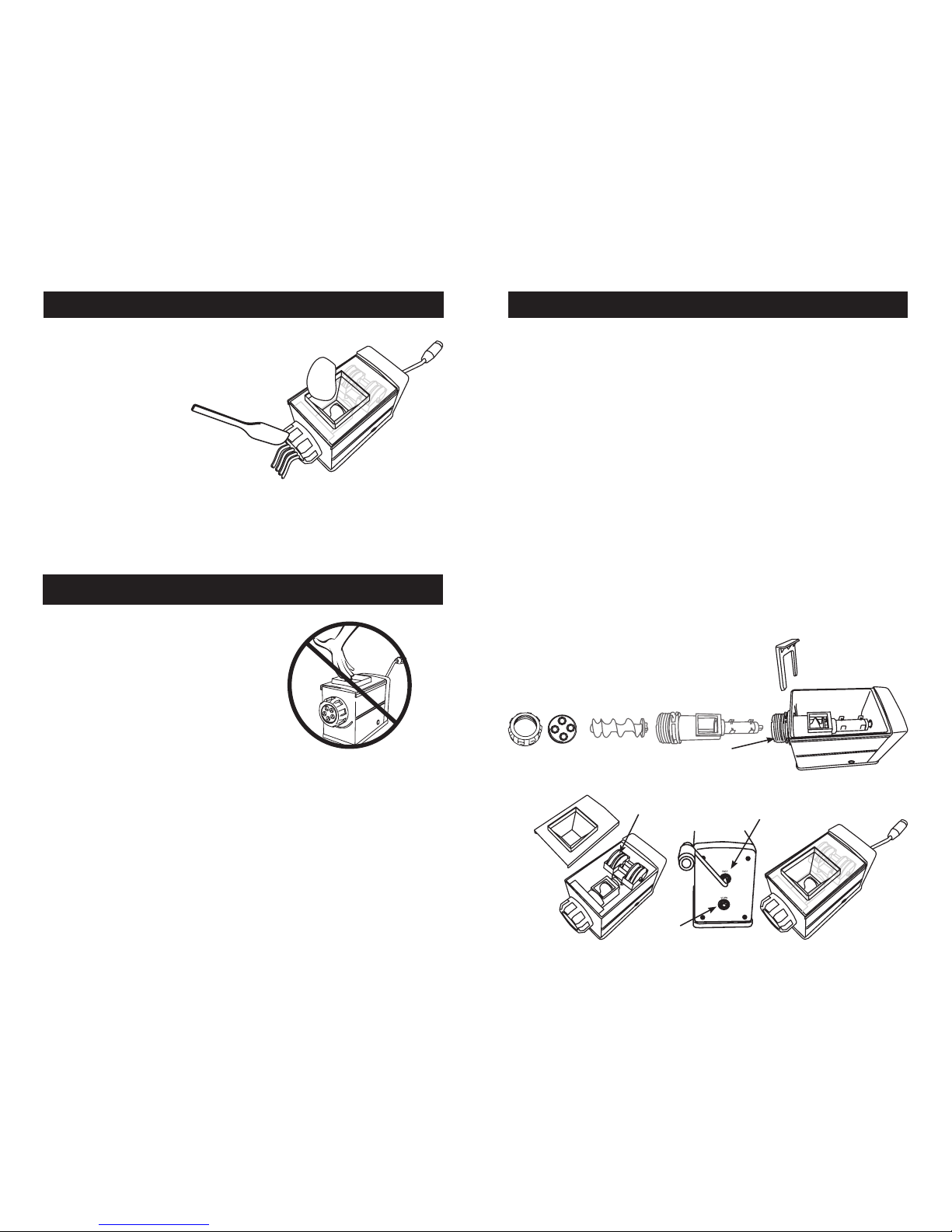

DIAGRAM PART PART

NUMBER DESCRIPTION NUMBER

1 Pasta Machine Body N/A

2 C-Clamp 01-0217

3 Handle 01-0216

4 Pasta Lid 01-0705

5 Auger Assembly 01-0703

A. Auger

B. Auger Housing

C. Auger Lock

6 Front Ring Nut 01-0706

7 Ring Nut Wrench 01-0707

8 Cutter Spatula 01-0708

9 Disc Kit 01-0704

D. Bucatini Disc

E. Mezze Penne Disc

F. Tortiglioni Disc

G. Rigatoni Disc

H. Fusilli Disc

I. Disc Rack

Not Shown Rubber Foot (4) 01-0211

10 Mixing Kit 01-0702

J. Mixing Paddle

K. Front Cap

L. Enclosed Mixer Lid

COMPONENT LIST

-3--14-

PART PART

DESCRIPTION NUMBER

Traditional Pasta Machine 01-0201

Deluxe Electric Pasta machine 01-0601-W

5.5 Quart Stainless Steel Colander 66-0105-W

Food Strainer & Sauce Maker 07-0801

Deluxe Electric Tomato Strainer 82-0202-W

ADDITIONAL ACCESSORIES AVAILABLE

These products and many more products can be ordered by visiting

WestonProducts.com or by calling

Weston Products LLC Toll Free at 1-800-814-4895

Monday thru Friday 8:00am-5:00pm EST. Outside the U.S. call 440-638-3131

If any components of this unit are broken or the unit does not operate

properly, call Weston Products LLC Toll Free at

1-800-814-4895

Monday thru Friday 8:00am-5:00pm EST. Outside the U.S. call 440-638-3131

There are basic rules to follow when handling food.

They are COOK, SEPARATE, CLEAN, and CHILL.

COOK

It’s crucial to cook food to a safe internal temperature to destroy bacteria that is present. The safety of

hamburgers and other foods made with ground meat has been receiving a lot of attention lately, and with

good reason. When meat is ground, the bacteria present on the surface is mixed throughout the ground

mixture. If this ground meat is not cooked to at least 160oF to 165oF (71oC to 74oC), bacteria will not be

destroyed and there’s a good chance you will get sick.

Solid pieces of meat like steaks and chops don’t have dangerous bacteria like E. coli on the inside, so they

can be served more rare. Still, any beef cut should be cooked to an internal temperature of at least 145oF

(63oC) (medium rare). The safe temperature for poultry is 180oF (82oC) and solid cuts of pork should be

cooked to 160oF (71oC). Eggs should be thoroughly cooked too. If you are making a meringue or other

recipe that uses uncooked eggs, buy specially pasteurized eggs or use prepared meringue powder.

SEPARATE

Foods that will be eaten uncooked and foods that will be cooked before eating MUST ALWAYS be

separated. Cross-contamination occurs when raw meats or eggs come in contact with foods that will

be eaten uncooked. This is a major source of food poisoning. Always double-wrap raw meats and place

them on the lowest shelf in the refrigerator so there is no way juices can drip onto fresh produce. Then

use the raw meats within 1-2 days of purchase, or freeze for longer storage. Defrost frozen meats in the

refrigerator, not on the counter.

When grilling or cooking raw meats or sh, make sure to place the cooked meat on a clean platter. Don’t

use the same platter you used to carry the food out to the grill. Wash the utensils used in grilling after the

food is turned for the last time on the grill, as well as spatulas and spoons used for stir-frying or turning

meat as it cooks.

Make sure to wash your hands after handling raw meats or raw eggs. Washing hands with soap and water,

or using a pre-moistened antibacterial towelette is absolutely necessary after you have touched raw meat

or raw eggs. Not washing hands and surfaces while cooking is a major cause of cross-contamination.

CLEAN

Wash your hands and work surfaces frequently when you are cooking. Washing with soap and warm

water for at least 15 seconds, then dry with a paper towel.

CHILL

Chilling food is very important. The danger zone where bacteria multiply is between 40oF and 140oF (4oC

and 6oC). Your refrigerator should be set to 40oF (4oC) or below; your freezer should be 0oF (-17oC) or

below. Simple rule: serve hot foods hot, cold foods cold. Use chang dishes or hot plates to keep food hot

while serving. Use ice water baths to keep cold foods cold. Never let any food sit at room temperature for

more than 2 hours - 1 hour if the ambient temperature is 90oF (32oC) or above. When packing for a picnic,

make sure the foods are already chilled when they go into the insulated hamper. The hamper won’t chill

food - it just keeps food cold when properly packed with ice. Hot cooked foods should be placed in shallow

containers and immediately refrigerated so they cool rapidly. Make sure to cover foods after they are cool.

NOTE: Special considerations must be made when using venison or other wild game, since it can become

heavily contaminated during eld dressing. Venison is often held at temperatures that could potentially

allow bacteria to grow, such as when it is being transported. Refer to the USDA Meat and Poultry

Department for further questions or information on meat and food safety.

FOOD SAFETY

CAUTION! It is important to follow the “Food Safety” guidelines outlined in this

manual. For the most up to date instruction visit the USDA website.