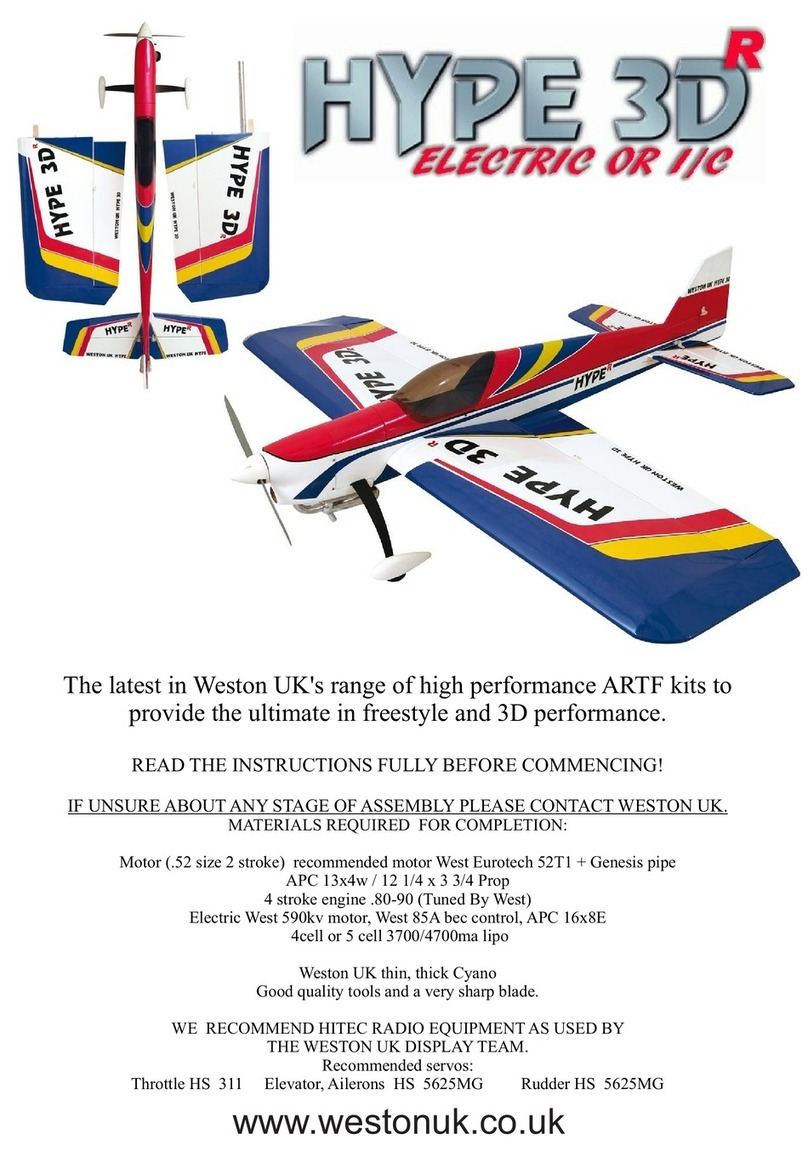

AILERON CONTROL HORN

Using the items as shown in the picture assemble

into the aileron. When you are happy and all set

up has been completed it is recommended to use

Weston Superlock to secure the bolt and nut

assembly.

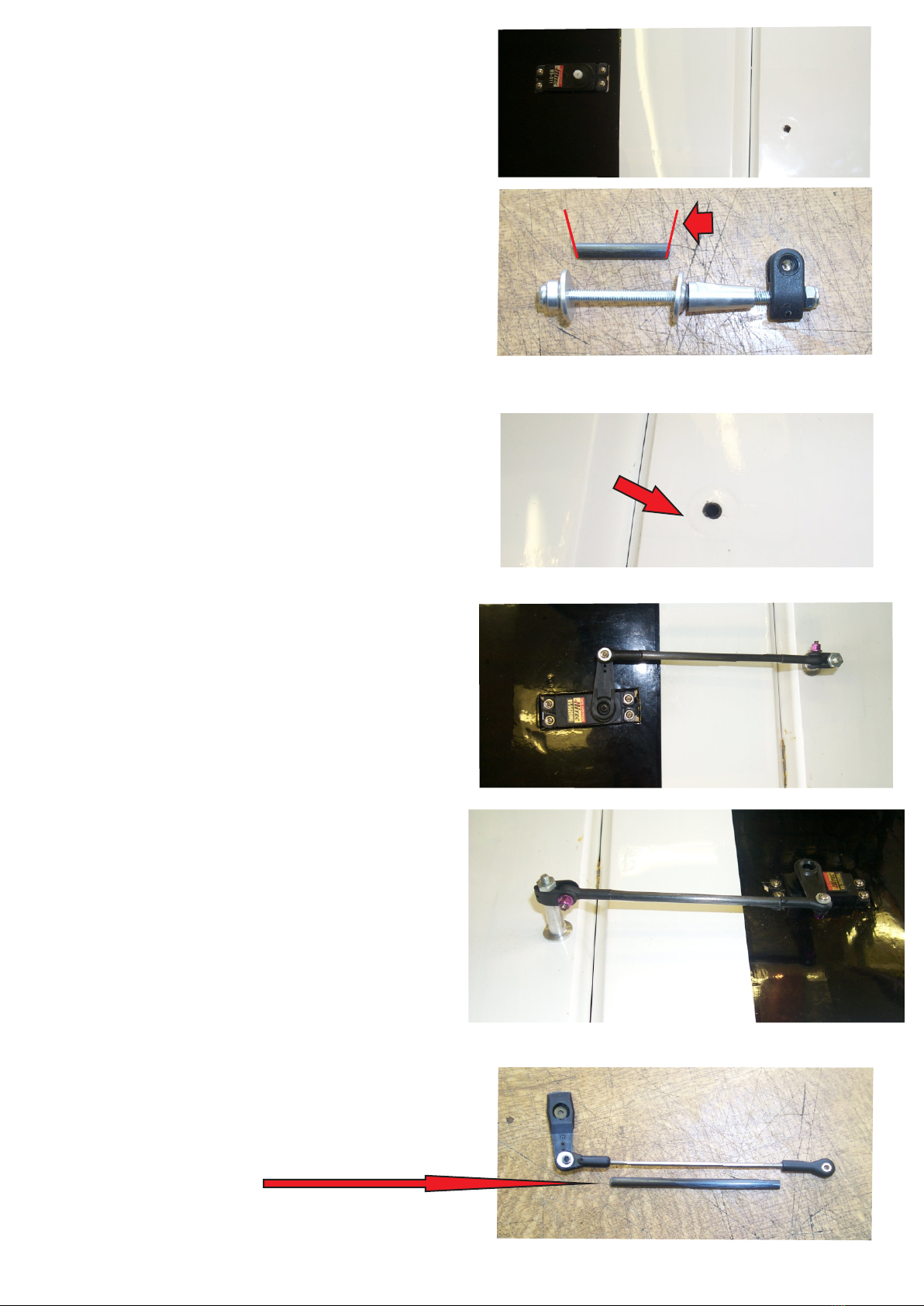

AILERON SERVOS

Pass the servo cable through the wing section to the

exit point in the centre of the wing. Install the servo so

the output arm is to the trailing edge of the wing and

screw into position. Take the aileron pushrods and

connect to the servo arm using the large ball link as

shown. Ensure that the servo and control surface are

both in the neutral position .

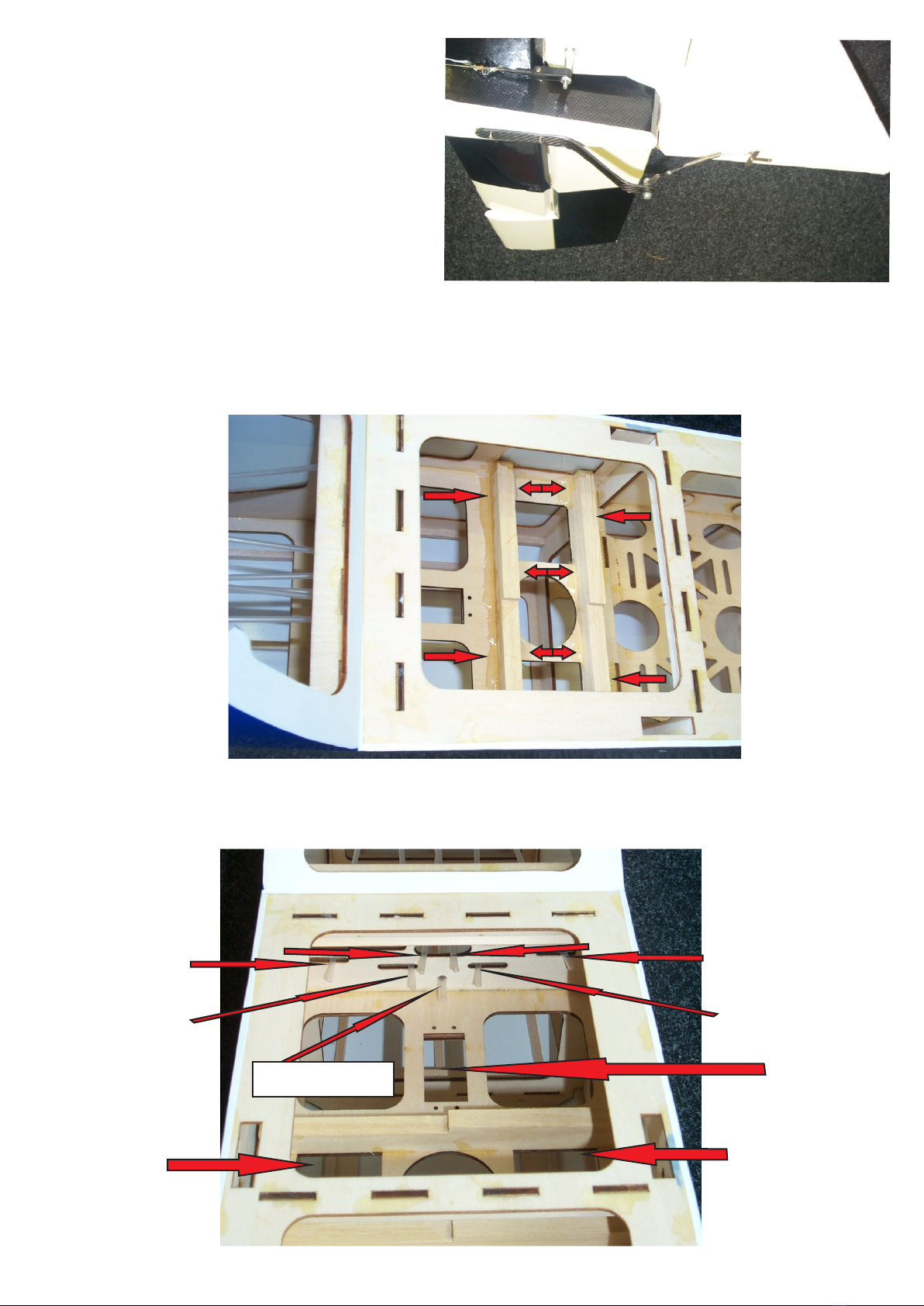

Control rod

With the servo installed and the control horn installed

and all in the neutral position make the control rod up

as shown. Using the supplied carbon tube cut to the

required length and wet assemble with slow cyano or

epoxy.

Repeat procedure on other aileron.

WE RECOMMEND DUBRO HEAVY DUTY

SERVO ARMS.

Carbon tube cut to length

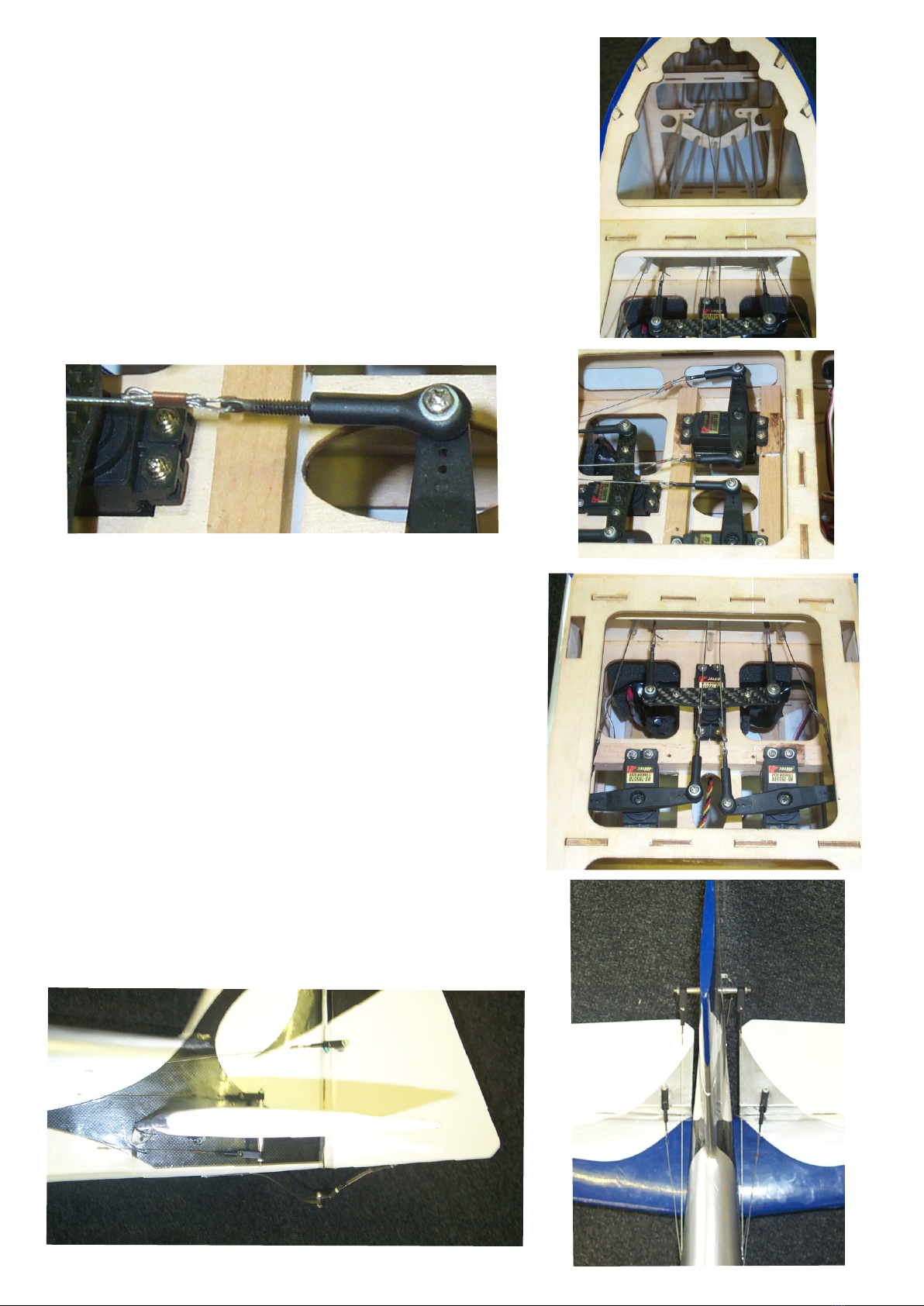

Using the control horns as a guide mark out the

hardwood points in the control surfaces and drill to

accept the control horn bolts. Please ensure that

the hole you drill has sufficient hard wood area is

around it and not too close to the edge. Then with

the supplied carbon tube of 4mm ID cut to length

with a razor saw or cutting disk as per pic with angled

ends to sit at the same angle as the control surface

angle. Re-drill the control surface to accept the carbon

tube, the carbon tube is to sit just below the surface

so as not to take the main load but to stop

any compression of the aileron when the control

horn bolts are done up tight. When happy run some

thin cyano to lock carbon tube in place.

CUT AT THE SAME

ANGLE AS THE

AILERON

CARBON TUBE GLUED

IN PLACE