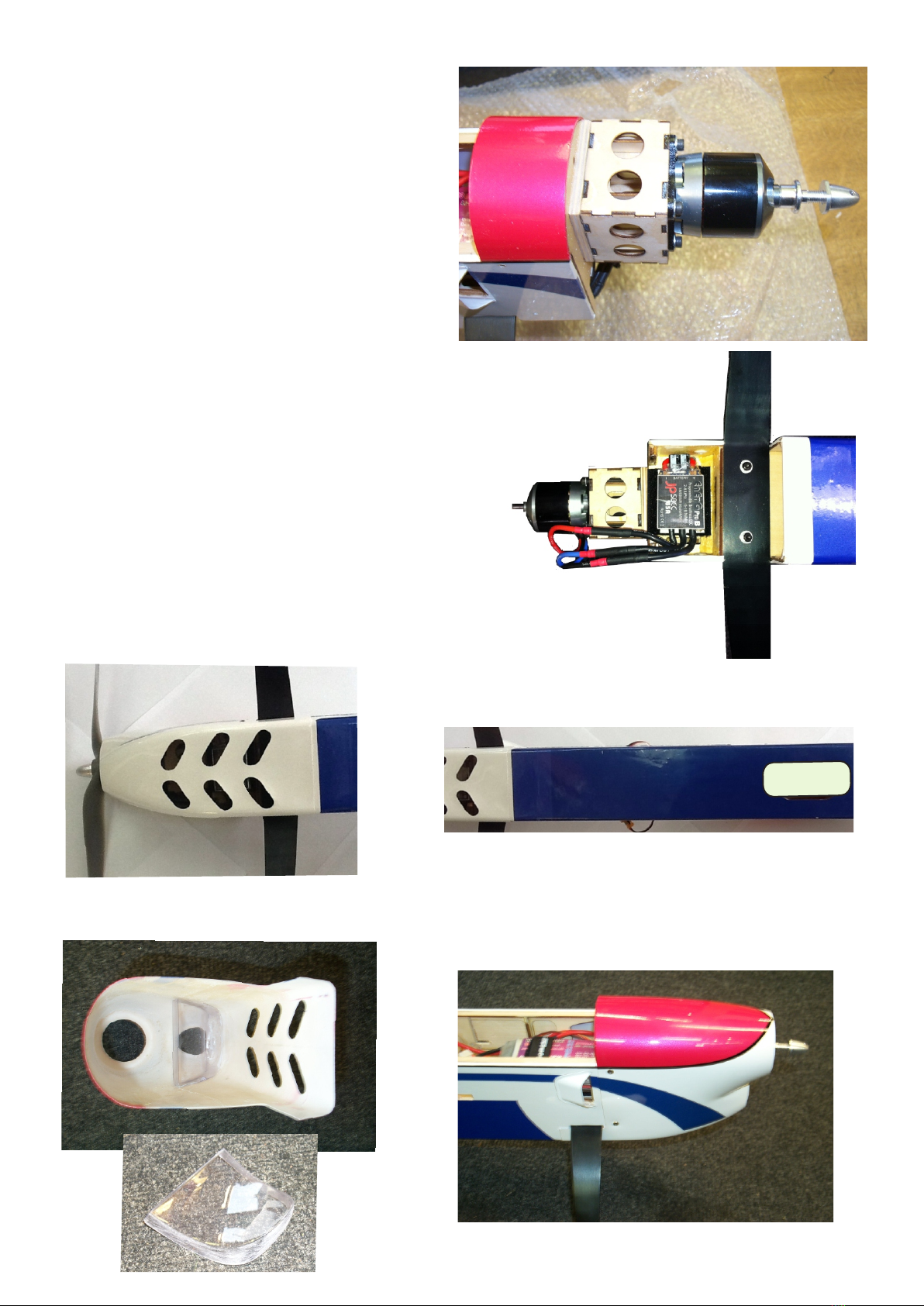

Battery installation

Depending on your chosen lipo 3 cell or 4 cell

will depend on where it is placed for your

required C of G. But once established it is a

good idea to install a small strap and velcro

to eliminate the movement of the battery.

SWITCH INSTALLATION

Install your receiver switch in the pre-cut slot in the side of the fuselage

COWLING

Once all holes have been cut and you are happy that there is no interference install cowling with bolts and

washers.

CANOPY

Install canopy to the hatch with Weston canopy glue or the self tappers provided.

RX BATTERY INSTALLATION(IC VERSION)

The battery installation will vary depending on engine used and C.G position require. A good starting point is

just behind the Rx, but if you want extreme 3D then behind the elevator servo which you will have to tie-wrap

it to the rear servo frame.

RX INSTALLATION

The Rx should be installed in foam and with all leads secured. A good position is just behind the spar.

SET UP

Use the nicad to adjust the C of G. The range for normal use is between and 140mm and up to 155mm for

experts - from the leading edge of the wing.

CONTROL MOVEMENT SET UP MEASURED FROM IN-BOARD POINTS

Intermediate : ailerons 25mm up and down EXPEDENTIAL

elevator 25mm up and down Intermediate: 15% - 30%

rudder 45 degrees side to side Expert 25% - 50%

Advanced: ailerons Max throw

elevator Max throw

rudder Max throw

FLAPERONS

It is not necessary to have flaperons but these can give incredibly tight loop manoeuvres.

WARNING

On take off and landing beware not to apply full elevator as this may cause damage to the elevator in long

grass.

REMEMBER

Before flying check your model and do a thorough range check. Check all electrical connections are solid and

restrained and the receiver is in a padded area.

We trust you will have many happy hours of flying this model!!

Weston UK, 84-88 London Rd, Teynham, Sittingbourne, Kent Me9 9QH, England

Tel: +44(0)1795 521030 Fax or Tel: +44(0)1795 522020, E- mail alan@westonuk

www.westonuk.co.uk

Quick release canopy option

If you have chosen the electric route you can easily

make a quick release canopy. Simply knock out the

capture nuts and use an inner and outer control rod

snake and a bit of fuel tubing at the ends.