76-5023-05 Page 8 of 20

Notice: The sequencer cover should be placed as follows:

Location

The location of the sequencer in the room should be such that it is not affected by air flows that could result in

wrong temperature readings.

Suggested locations vary according to the position of the conditioning unit.

a) Both units on the same side b) One unit each side

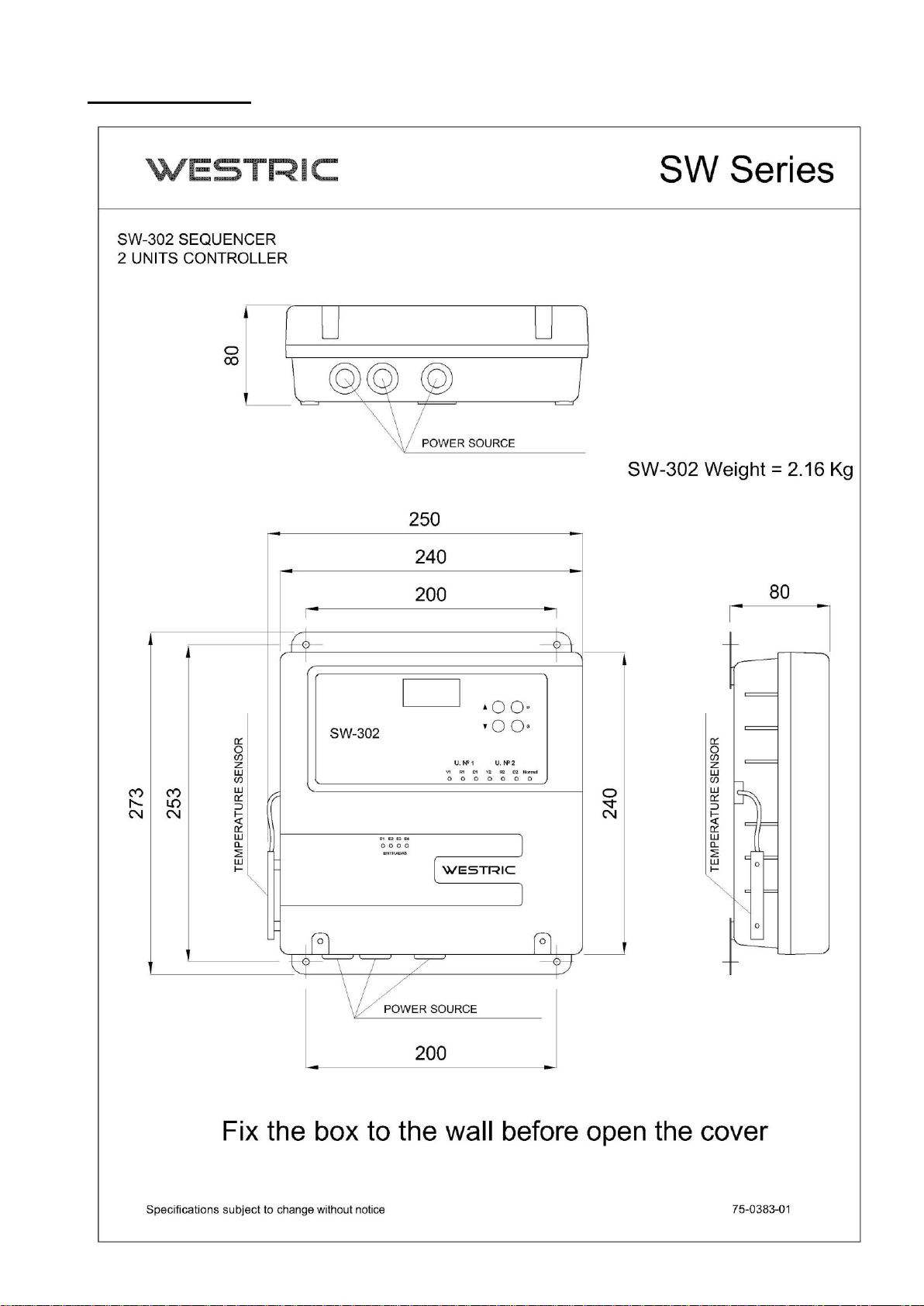

Mounting

The sequencer assembly on the wall of the room must be made through the two holes located on the outside of the

top and the two located on the bottom, without disassembling the cover, to prevent dust from entering the

controller.