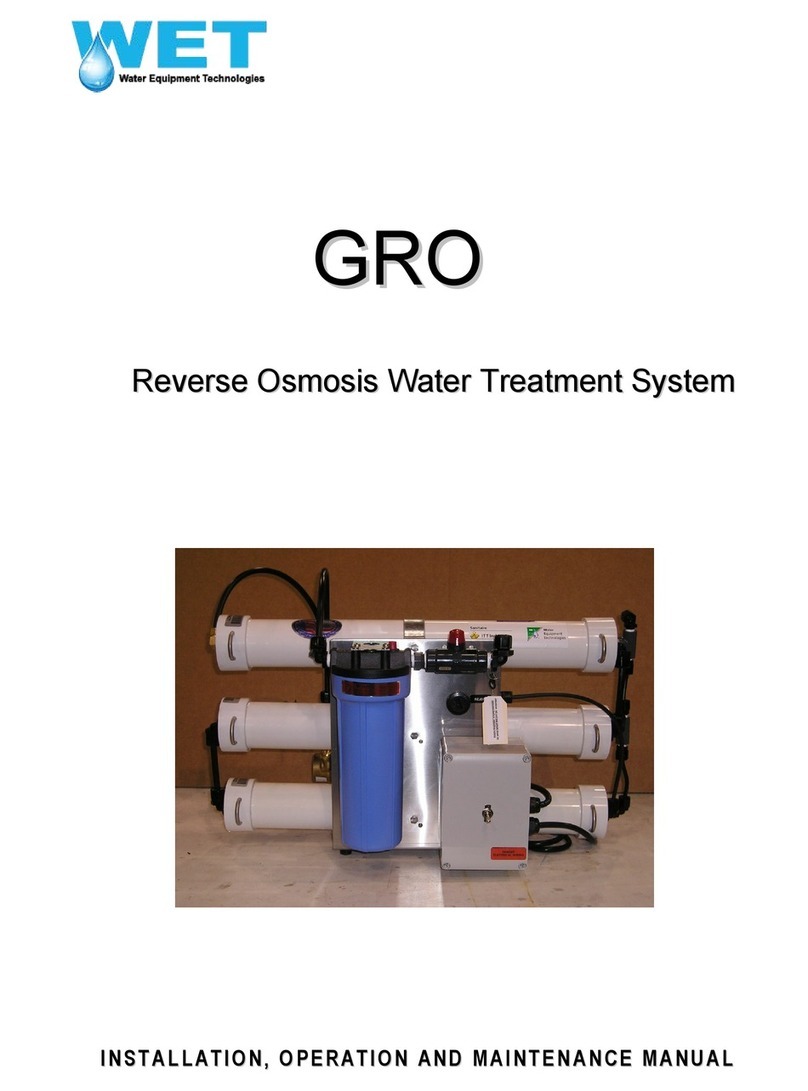

System Description

Theory of Operation

Feed water is supplied to the RO unit through a inlet valve. Next, the feed water passes through a

pre-filter for removal of suspended particles 5 microns or larger.

The filtered water enters a high-pressure pump where the water pressure is increased to RO

operating levels and is directed into the 1st stage RO membrane assembly. Inside the membrane

assembly, a portion of the feed water, referred to as product or permeate, passes through a

membrane barrier that rejects suspended and dissolved solids. The remaining portion of feed

water, referred to as reject or concentrate, carries concentrated contaminants out of the membrane

assembly. This reject water is sent to the 2nd stage RO membrane assembly, which extracts

additional product water.

The reject water, upon leaving the 2nd stage RO membrane assembly, is regulated by a Reject

valve, and is monitored by a flow indicator, before leaving the system to waste.

The combined product water from both the first and second stage RO membranes is monitored by

a conductivity sensor and analytical instrument to determine the Total Dissolved Solids content of

the product water.

Recovery, an important operating parameter, is the ratio of the product water to the feed water

flow. See the System Specifications section of this manual for details.

The ES Series of RO systems will produce high quality water from either municipal or well

water supplies. The reverse osmosis process uses a semi-permeable spiral wound membrane

to separate and remove dissolved solids, organics, pyrogens, submicron colloidal matter, and

bacteria from water. The feed water is pressurized to approximately 130 PSI forcing the water

molecules through the minute pores as purified water. Impurities in the water are generally too

large to pass through the pores and they are concentrated in the "reject" stream and flushed to

the drain. The RO membranes are capable of removing 90 - 99% of Total Dissolved Solids

(TDS), and up to 99% of organics, pyrogens and bacteria that may be in the feed water.