Thank you for purchasing this Whale Instant atch® Bluetooth®

wireless technology product. Whale®is the market leader in pumped

shower drainage kits. These kits have the reputation of working reliably

for many years without requiring maintenance.

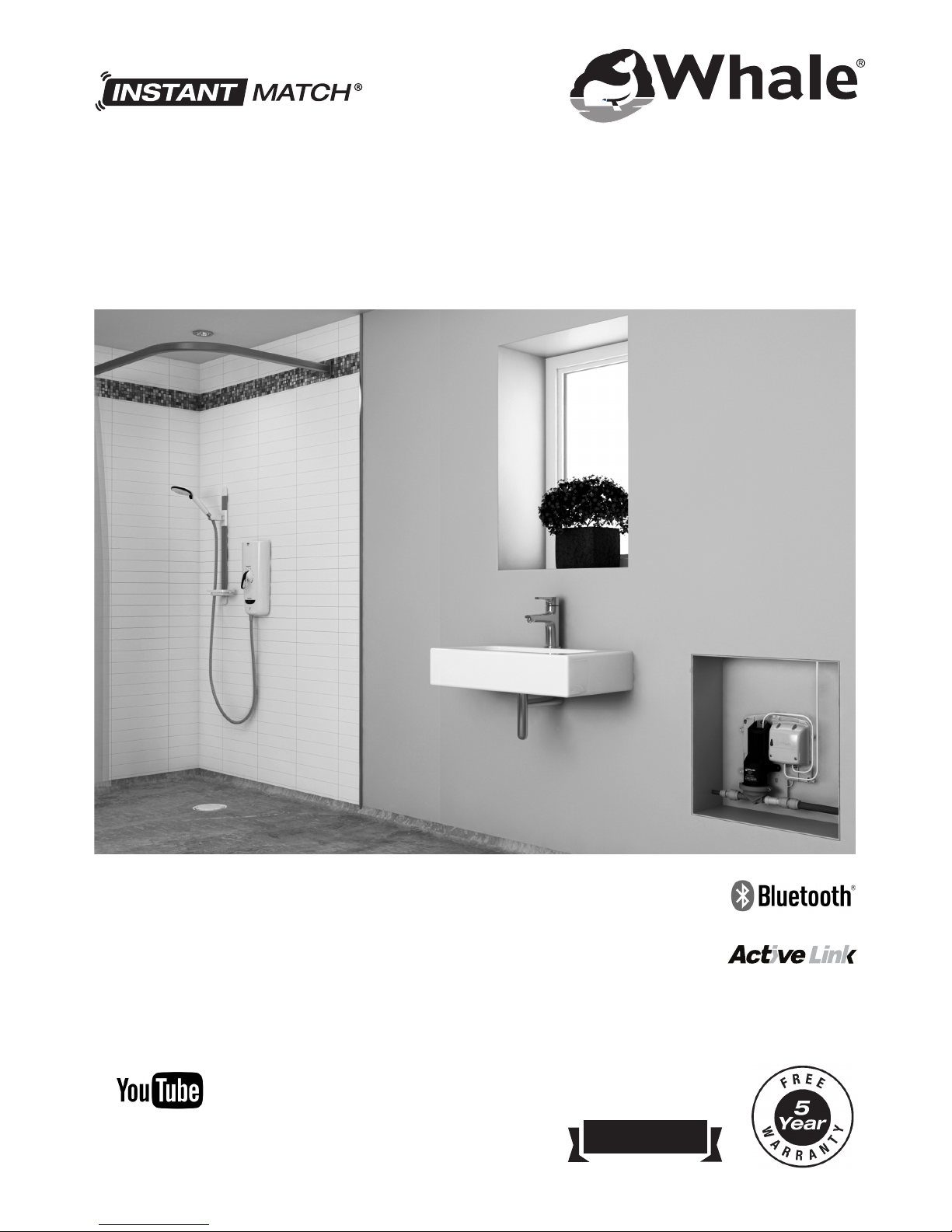

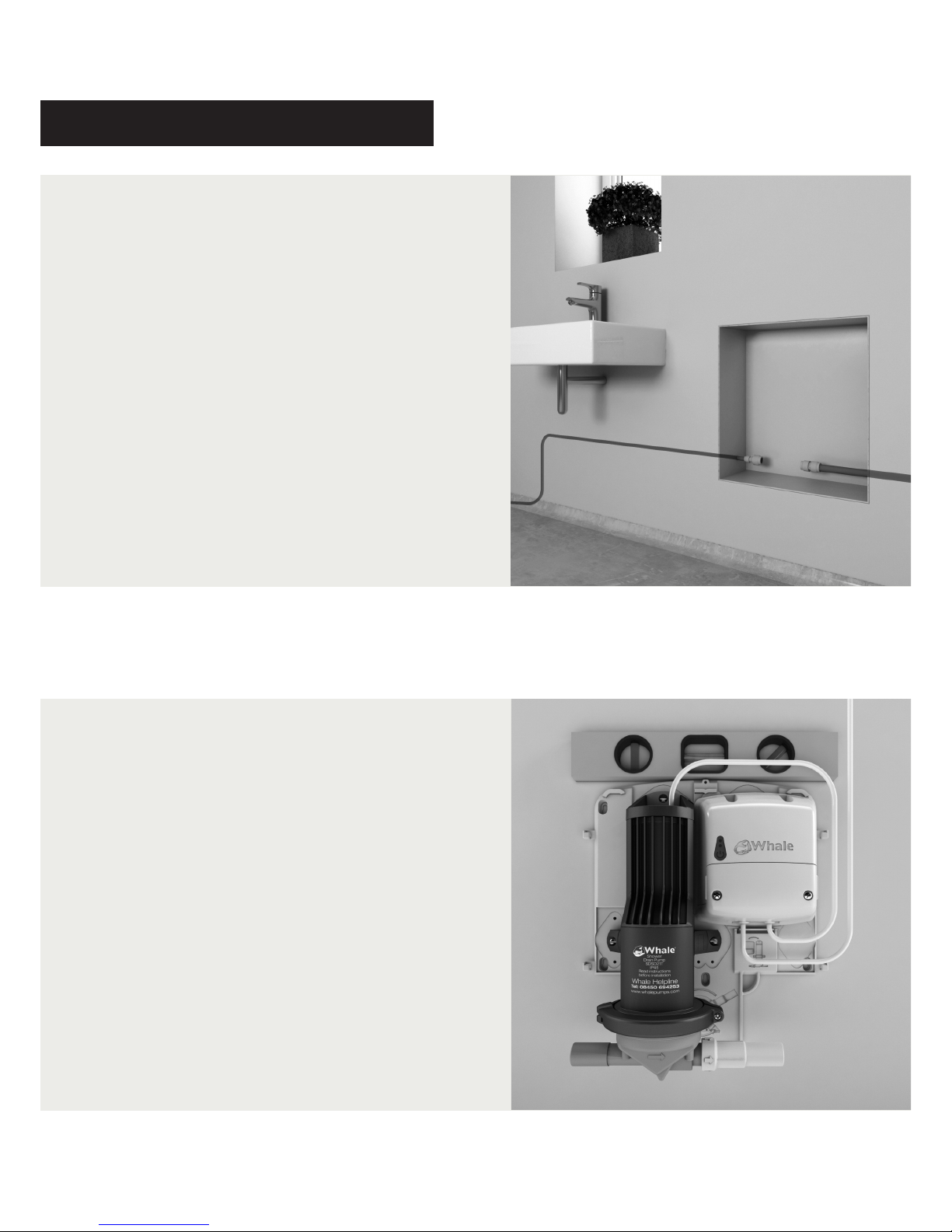

The front cover shows the product installation in an apartment with the components in a concealed access.

Assess your installation prior to fitting to ensure that the unit will be situated in an accessible location.

Typical installations would have these components in an adjacent cupboard i.e. airing cupboard or in a false

wall with an access panel. Do not fit the pump cover in these locations.

Incorrect installation may invalidate the warranty.

Principles of Operation

This kit has been designed for the pumping of shower waste water. The Whale Instant Match® with Bluetooth® wireless

technology control unit uses the flow signal from the shower to measure the flow rate of water into the shower. The

control unit uses the signals sent from the flow sensor to adjust the pump speed to match the flow of water from the

shower. This minimises suction noise at the gulley. When the shower is turned off, the flow sensor sends a signal to

the control unit and after a pre-set time delay the pump turns off. After a further 15 minutes the pump will automatically

switch on for a short period of time at a reduced pumping speed, removing any run off water pooled in the shower area.

The pump has the ability to run dry without causing damage. Non-return valves in the pump head prevent smells

entering the bathroom area from the waste pipe.

Installation Warnings

Before installation please read the instructions. All electrical and mechanical components (transformer and pump) must

be accessible after installation.

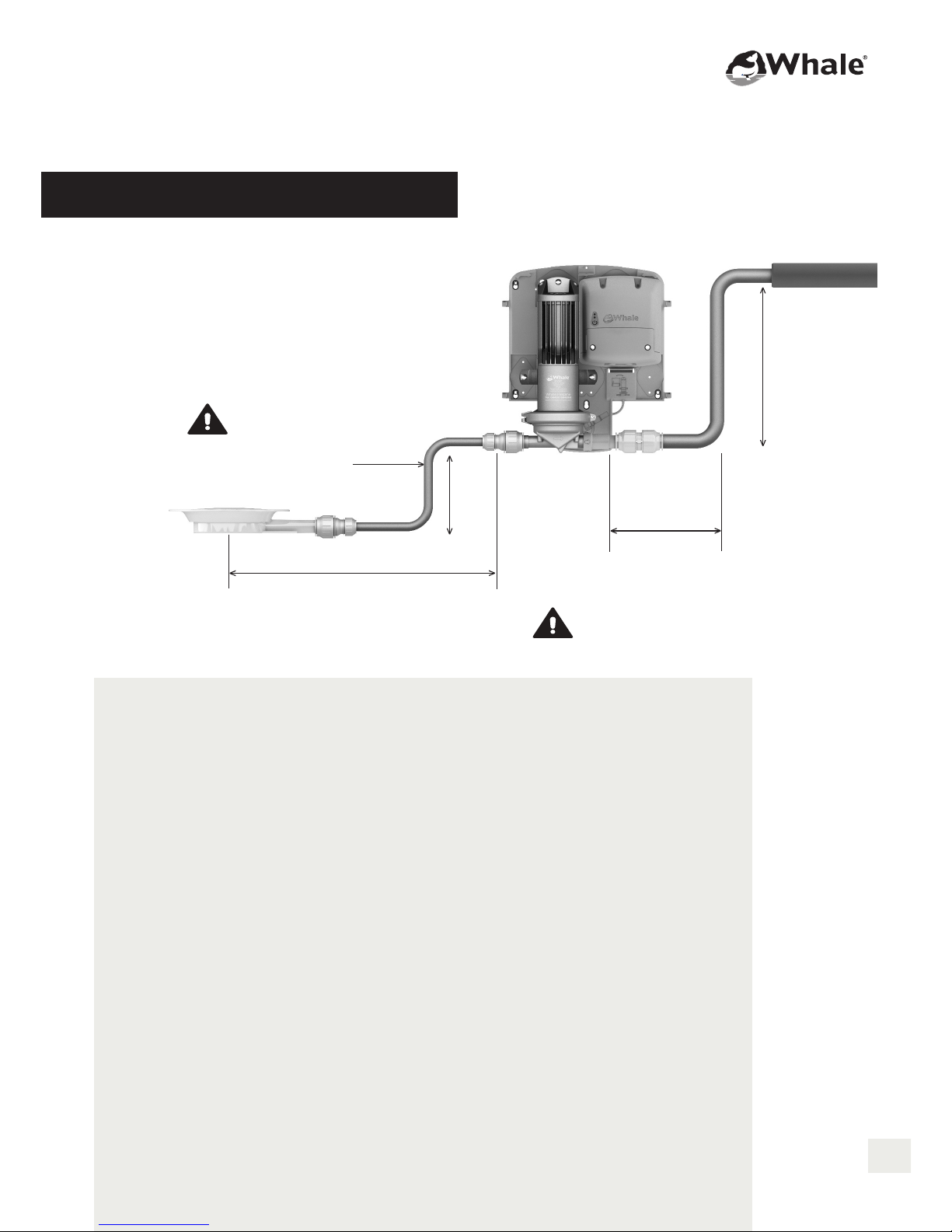

• The Whale Instant Match® with Bluetooth® wireless technology is designed to work on shower bases with a minimum

of a 1:40 fall to the gulley. Where the fall is insufficient, the water will not refill the gulley rapidly enough and so suction

noise will be increased. We recommend the use of a shower former as this eliminates the risks of pooling caused by

insufficient fall to the gulley.

• Forming a shower base by hand is a highly skilled task and should be carried out by a trained installer. Do not

attempt this if you are unsure and seek professional advice.

• The maximum flow rate of the shower that the pump is designed to work with is 8 ltrs/min.

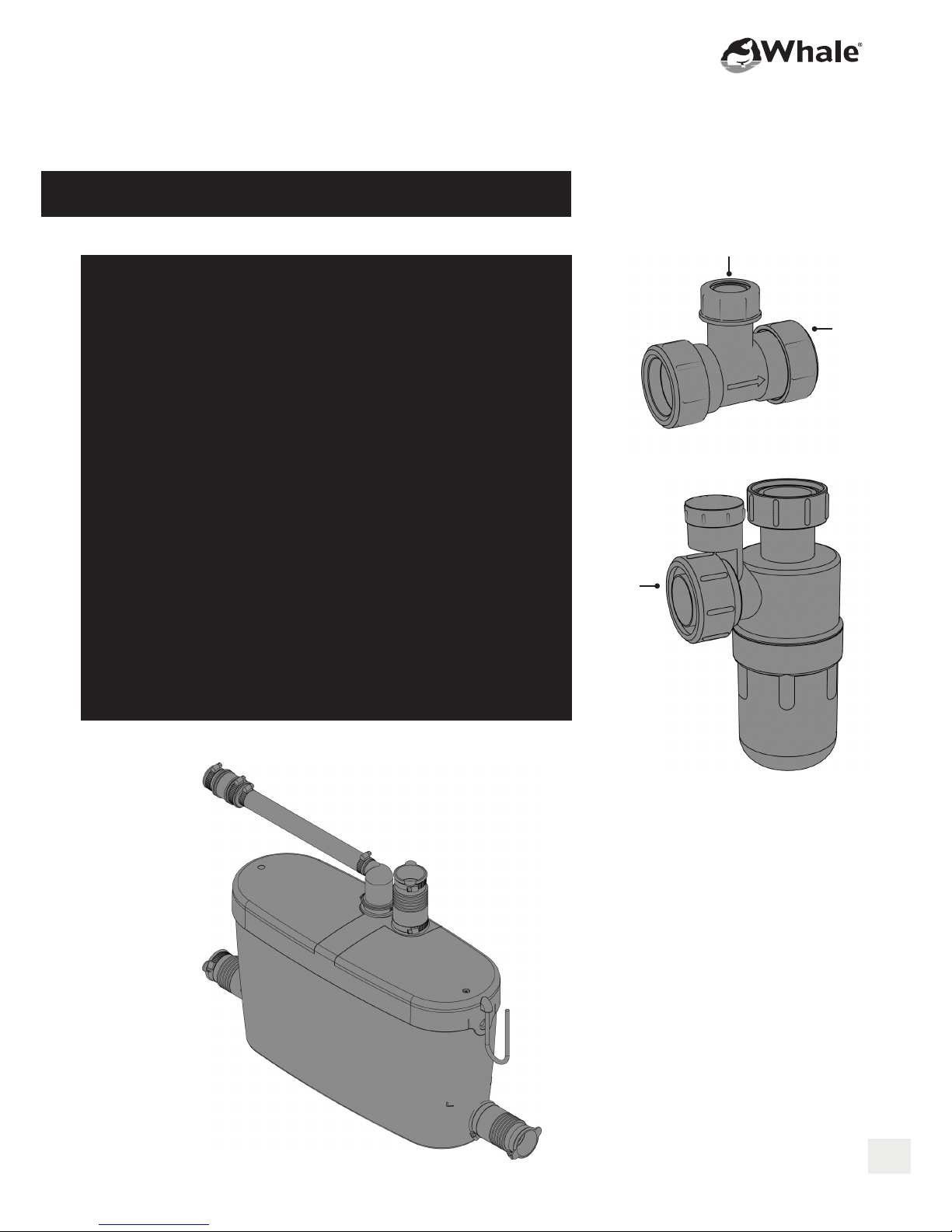

• Avoid plumbing the pump outlet into the waste piping that other appliances drain into as there is a risk of

induced syphoning. Use an anti-syphon trap in these situations. (See page 7)

• In installations where the floor is being formed in the screed, we recommend the following minimum falls:

40mm in 1m, 20mm in 500cm,10mm in 250cm.

• Plumbing must comply to latest WRAS standards.

• The electrical wiring must conform to EU wiring regulations BS7671:2008 Part 7 (17th Edition).

• Pipework must be secured to prevent vibration and noise.

• Ensure that the water fall from the shower head is as close to the gulley as possible.

WARNING

3