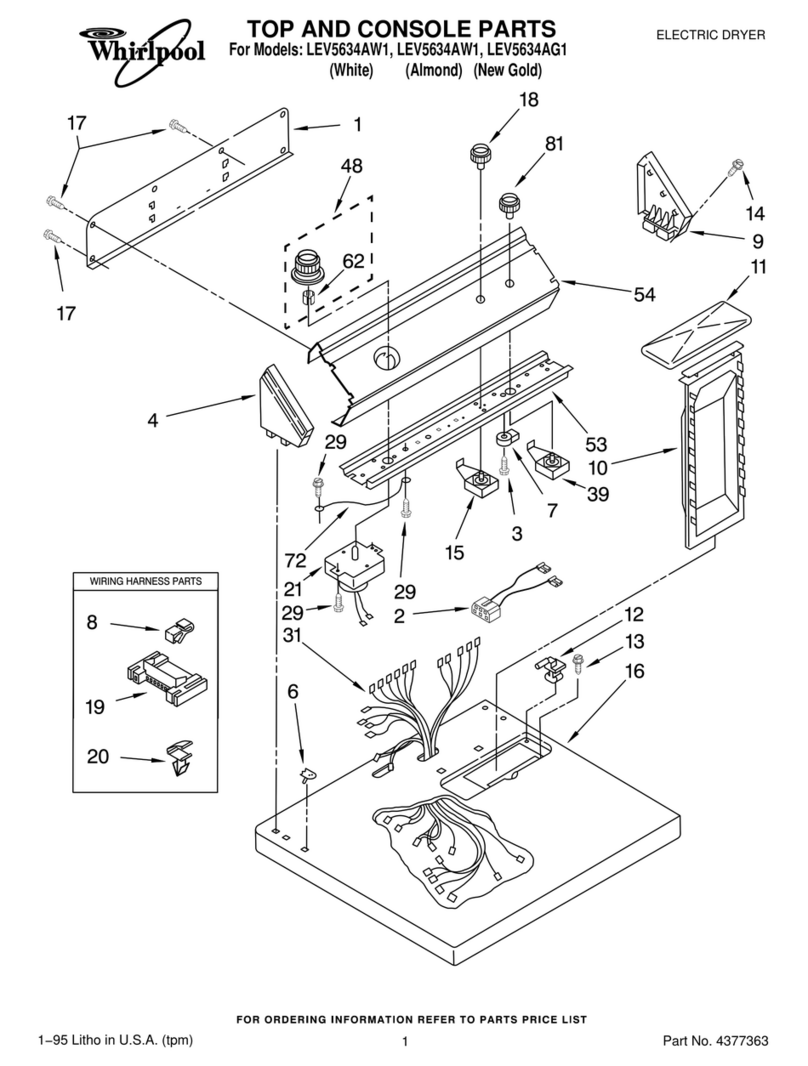

Electrical

requirements

Observe all governing Codes

and Ordinances.

1 A two wire, single phase, 220 Volt,

50 Hz, AC only, electrical power

supply is required on a separately

fused 15 Ampere circuit. [Time

delay fuse or circuit breaker is

recommended.)

2. An adequate electrical ground is

required within 4 feet of the

appliance location when using the

grounding wire supplied.

3. THEDRYERMUSTBECONNECTED

TOCOPPERWIREONLY.Aluminum

wire must not be used to avoid

potentially unsatisfactory

connections.

4. Local codes may permit the use

of a flexible type electrical power

supply cord (pigtail). A suitable

strain relief must be provided at the

point the power supply cord enters

the appliance.

5. The appliance may be connected

directly to the fused disconnect (or

circuit breaker) box through flexible

armored or non-metallic sheathed

cable. Allow two or three feet of

slack in the line between the wall

and the appliance so that it may

be moved if servicing is ever

necessary A suitable strain relief

must be provided at each end of

the electrical power supply cable

(at the appliance and at the

junction box). Wire sizes and

connections must conform with

the rating of the appliance

(15Amperes). DO NOT use an

extension cord.

Electrkaf

Connection

220 Volt - Single Phase -

2-Wire Connection

Electrical ground is required on

this appliance.

This appliance is manufactured with

the neutral terminal NOT connected

to the frame.

CONNECT GROUND

TO FUSED DIS- n

WIRE TO APPROVED

CONNECT BOX

OR APPROVED

WIRING DEVICE

FOR POWER

/ (15AMPERES)

Connect the power supply cord

as follows:

1.

Remove the terminal block cover

2. Connect the two wires of the power

supply cord to the outer terminals of

the terminal block. See Figure 1.

For connecting plain-end field wire,

see Figure 2,

3. Replace terminal block cover

NOTE: Plain-end fieid wires must be

fastened between the terminals of

the terminal block and the nuts of the

terminal block screws as shown in

CONNECT GROUND #ii n

Figure 2

POWER SUPPLY (

(WITH STRAIN RE

(15AMPERES)

WIRE TO APPROVED

GROUND

4. Connect a separate copper’

grounding wire (No. 10 minimum] to

a grounded cold water pipe* by

means of a clamp and then to the

frame of the appliance at the

external grounding connector Use

Part No. 685463 grounding wire and

clamp assembly. Do not ground to

a gas supply pipe. Do not connect

PANEL

B

the power supply cord to electric

power supply until appliance is

permanently grounded.

must have metal contfnuiy

to electrical ground and not be

Figure 3

Metrupted by plastlc, rubber or other

electrically nsulatlng connectors (fncludlng

water meter or pump] wIthout addlng a

jumper we at these connectlam

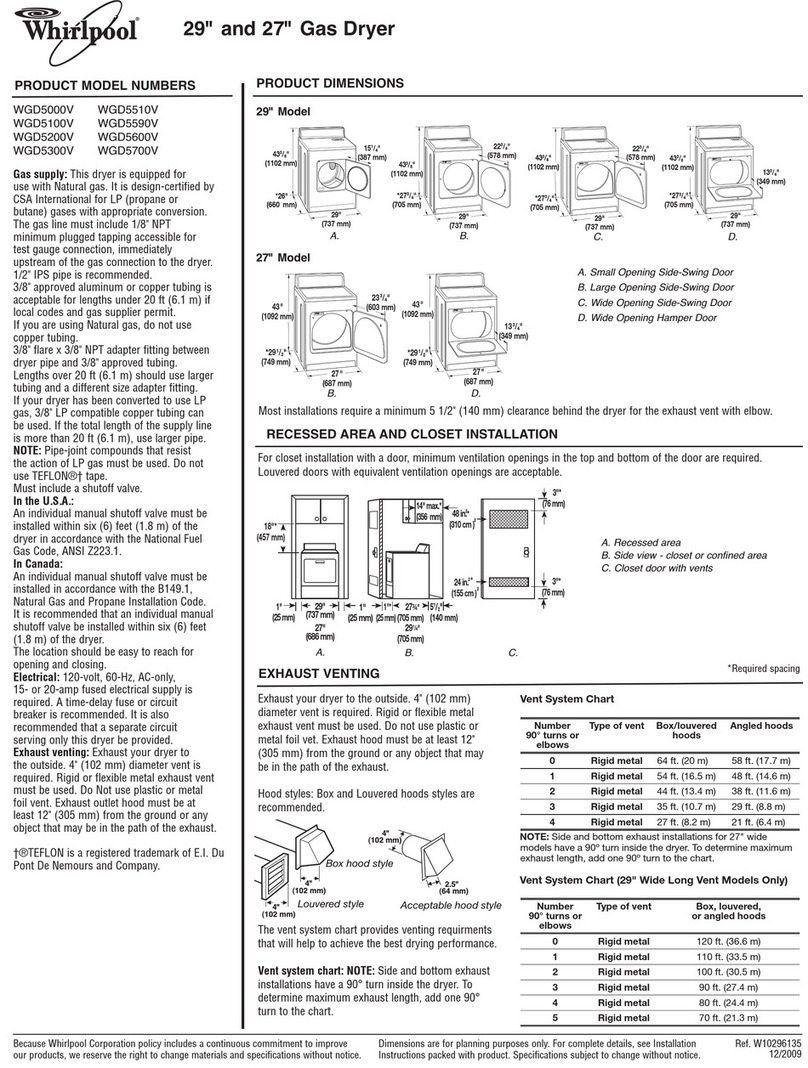

Exhaust

requirements

WARNING:

Metal

flexible duct may be used.

Non-metallic flexible duct is

not

recommended since it is a potential

fire hazard.

For Safety:

Do not exhaust dryer into a chimney,

furnace cold air duct, attic or crawl

space, or any other duct used for

venting. Accumulated lint could

become a fire hazard or moisture

could cause damage.

Clean the exhaust system

periodically, at least every 2 years.

Never install flexible duct

concealed in walls,

ceiling or under flooring.

Four Inch Metal Exhaust

Duct

is recommended.

(Do

not

use 3-inch exhaust due

Use Duct Tape

to seal all joints.

Exhausting the dryer outside

is

recommended. If you cannot exhaust

the dryer to the outside, use Exhaust

Deflector Kit LCK4000 available from

your Whirlpool dealer

of the dryer back.

The

Exhaust Duct

can be routed

up, down, left, right or straight out

the back of the dryer.

Metal Flexible Duct

must be

fully extended and supported

when the dryer is in its final

position. DO NOT KINK OR

CRUSH THEDUCT

An Exhaust Hood

should cap the

exhaust duct to prevent exhausted air

returning into dryer The outlet of the

hood must be at least 12 inches from the

ground or anything else that may be

in the path of the exhaust.

A 2% inch outlet Exhaust Hood

should

be used with short systems only. [This

outlet creates greater back pressure

than other hood types.)

Exhaust Hoods

with magnetic latches

should

not

be used.

The

Maximum Length

of the exhaust

system depends upon the type of duct

used, number of elbows and type of

exhaust hood. The maximum length for

both rigid and flexible duct isshown

in chart.

EXHAUST HOOD TYPE I

Exhaust Systems

longer than specified

will:

l

Shorten the life of the dryer.

l

Reduce the performance in ways

such as causing longer drying times

and increasing the use of energy.

l

Accumulate lint.

For

Exhaust Systems

not covered by

the exhaust length chart, see Whirlpool

Service Manual, Exhausting Whirlpool

Dryers, Part No. 603197 available from

your Whirlpool parts distributor The

back pressure in any exhaust system

used must not exceed .6 inches of water

column measured with an inclined

manometer at the point that the exhaust

system connects to the dryer

There are

Exhaust Kits

available that

allow you to direct filtered exhaust air

inside to conserve energy during winter

months. Whirlpool has a Heat-Humidity

Saver Part No. 279427 which can be

used with Whirlpool dryers providing

their use does not violate national

or local codes. If you use one of these

kits, be aware that excessive moisture

in the home can cause many

problems and that you may see an

increase in the time required to dry

a load. Also, you must regularly clean

the filter to avoid excessive lint

build-up which can affect the dryer’s

performance.

NOTE:Do not

use this kit on a dryer

installed in a bedroom, bathroom, or

closet.

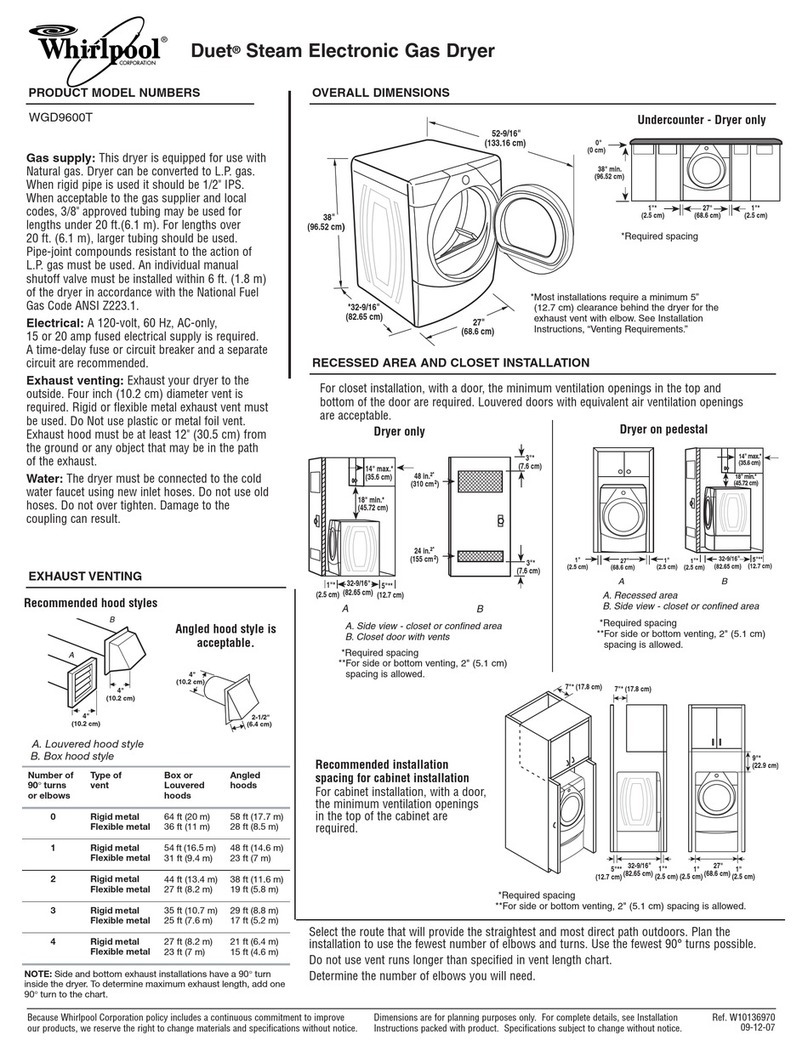

RecessedArea

Instructions

INSTRUCTIONSFORRECESSEDOR

CLOSETINSTALLATIONS

The following installation spacings

and door air openings for the dryer

are possible when installed and

exhausted as noted. [Spacing as

indicated is in inches and is minimum

allowable. For ease of installation and

service, additional spacing should

be considered.)

TO PREVENTLARGEAMOUNTS

OF LINTAND MOISTUREFROM

ACCUMULATING AND TO MAINTAIN

DRYING EFFICIENCY,THISMACHINE

MUSTBEEXHAUSTEDOUTDOORS.

MINIMUM INSTALLATIONSPACING

RECESS INSTALLATION A B C ‘r E

NON-EXHAUSTED (DEFLECTOR . O O 4 -

LCK4000 REQUIRED)

EXHAUSTED

Unobstructed air openings required for laundry

equipment when door is installed.

*Shelf or cabinet is not permitted above dryer

when non-exhausted

**Louvered door with equivalent air openings

is acceptable.

***“D” Dimension must be measured from dryer

cabinet rear panel.

Companion appliance spacings

should be considered.

Detailed space requirements can be

found on the label located on the

back panel of dryer

NOTE: No other fuel burning appliance

may be installed in the same closet.