Electricalconnection

Electrical Shock Hazard

Electrical ground is required on this range.

Do Not connectto the electrical supply until

the range is permanently grounded.

Disconnectthe power to the junction box

before makingthe electrical connection.

This range must beconnected to a grounded,

metallic, permanent wiring system or a

grounding connector should be connected to

the grounding terminal or wire lead on the

range.

Failure to follow these instructions could

resultin death or serious injury.

Pull coverdown

and remov_7

2mounting

tabs,

screws

Remove theterminal block cover screws

located onthe backof range. Pullcover

down and towards you to remove cover from

range.

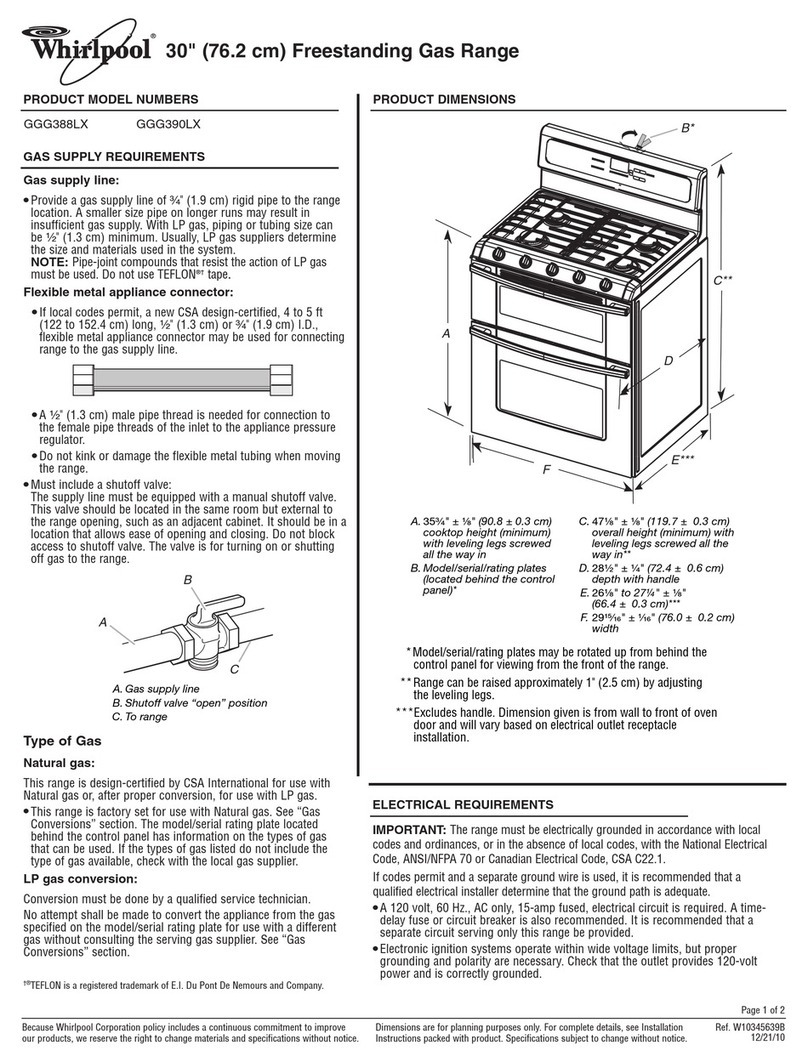

Depending on your electrical supply,

•make the three-wire or four-wire

connection following the "Power supply cord

method" or "Direct wire method" instructions.

This range is manufactured with the neutral

terminal connected tothe cabinet. Use a three-

wire, U.L.-listed, 40-ampere power supply cord

(pigtail); or if local codes Do Not permit

grounding through the neutral, use a four-wire

power supply cord rated at 250 volts, 40-amperes

and investigatedfor use with ranges. (See "Four-

wire electrical connection.")

remove knockout//_ing for

for40-ampere \._._ _conduit

power cord and _=::::_r,.-_"_ _ connector

U,L listed strain _,, _.,_,....._..._

rehef

1,Disconnect the power supply.

2. Remove the knockout for the 4g-ampere

power supply cord.

3. Assemble a U.L-listed strain relief in the

opening.

4. Insert the power supply cord through the

strain relief, allowing enough slack to easily

attach the wiring to the terminal block.

5, Use only ring-type terminals to connect the

power supply. To secure the power supply

cord, use the 3/8' brass terminal nuts attached

to the inside of the terminal block cover, Be

sure nuts are installed tight.

6, Complete electrical connection according to

your type electrical supply ("Three-wire

electrical connection" or "Four-wire electrical

connection.')

Three-wire electrical connection:

silver-colored

terminal

block screw..,,

link

(center wire)

U,L-listed strain relief

and 4a-ampere range

power supply cord

Figure3

Usethis method ONLY if local codesPERMIT

connectingcabinet-grounding conductorto neutral

wire of power supply cord.

7. Use the brass terminal nuts attached to the

inside of the terminal block cover to connect the

neutral wire (center wire) to the silver-colored

terminal screw on the terminal block.

See Figure 3,

8. Connect the other two wires to outer terminal

screws on the terminal block. See Figure 3.

9. Do Not loosen factory-installed nuts already on

the terminal. Tighten nuts with 3/8' nut driver

for proper electricalconnection.

10.Tighten the strain relief screws.

11,Replace the terminal block cover.

12. Plug power supply cord into grounded electrical

outlet.

Four-wire electrical connection:

i_rounding-

nk

Figure4

grounding

9roundingJink

screW

silver-colored

terminal

neutral wire

(canter wire)

reerl

grounding wire

line 2

Figure5

U.L listed strain relief

and 40-ampore range

power supply cord

Usethis method for mobile homes and whenever

four-wire installation is required,

7. Remove the grounding-link screw from the

range frame, Save the grounding-link screw.

Bend up the grounding link so that it does not

contact the range. See Figure 4.

8. Connect the green grounding wire from power

supply cord to the range using the grounding-link

screw, The groundingwire must be attached first

and must not contact anyother terminal.

See Figure5,

9. Connectthe neutral wire (center wire) to the

center, silver-coloredterminal screw on the

terminal blockusing the brassterminal nuts that

are attached to the inside ofthe terminal block

cover, See Figure5,

10.Connectthe othertwo wires to the outer

terminals on theterminal block.See Figure5.

11.Do Not loosenthe factory installed nuts already

on the terminal. Tighten nutswith 3/8' nut driver

for proper electricalconnection.

12.Tighten the strain relief screws.

13. Replacethe terminal blockcover.

14. Plug power supply cord into grounded electrical

outlet.

This range may be connected directly to the fuse

disconnector circuit breaker box; or with a U.L.-listed,

4a-ampere range power supply cable, Depending on

your electrical supply, make the required three-wire or

four-wire connection.

1.Disconnect the power supply.

2. Remove the knock-out for the

power supply cable.

3. Assemble a U.L.-listed conduit

connector in the power supply

cable opening.

4. Strip outer covering back 3 inches

from end, exposing wires.

,

6.

U.L-listed conduit

connector,

Strip the insulationback

1inch from the end of _1-3"-_

each wire.

Form the bare wire into a "U"

shaped hook. _1, -'_J _--

Insert the power supply cable

through the conduit connector, allowing enough

slack to easily attach the wiring terminal block.

Complete electrical connection accordingto your

type electrical supply ("Three-wire electrical

connection" or "Four-wire electrical connection.")

Three-wire electrical connection:

grounding

link

silver-colored

screw

line neutral

o (white wire)

Figure 6 connector

and power supply cable.

Usethis method ONLY if local codesPERMIT

connecting cabinet-grounding conductorto neutral

wire ofpower supply cable.

8. Use the brassterminal nuts attachedto the inside

of the terminal block cover to connect the neutral

wire (white wire) to the silver-colored terminal

screw on the terminal block. See Figure 6.

9. Connect the other two wires to outer terminal

screws on the terminal block. See Figure 6.

10. Do Not loosen factory-installed nuts already on

the terminal. Tighten nutswith 3/8" nut driver for

proper electricalconnection.

11.Tighten the locking ring and clamping screws of

the conduit connector.

12. Replacethe terminal blockcover.

Four-wire electrical connection:

grounding-

link

Figure7

screw

,ailver-colored

_H}"_"- \\U /t=:rremiwnalblock

_neutral wire

bare wire _ (white wire}

from power II

line 1fu.,.listed

connector and

Figure8 __ powersupply

cable

Usethis method for mobile homes and whenever

four-wire installation is required.

8. Remove the grounding-link screw from the range

frame. Save the grounding-link screw, Bend up

the grounding link so that it does not contact the

range. See Figure 7.

9. Connect the bare grounding wire from power

supply cable to the range using the grounding-

link screw,The grounding wire must he attached

first and must not contact any other terminal.

See Figure8,

10,Connect the neutral wire (white wire) to the

center,silver-coloredterminal screw on the

terminal block usingthe brassterminal nutsthat

are attachedto the inside of the terminal block

cover,See Figure 8.

11. Connectthe othertwo wires to the outer

terminals on the terminal block.See Figure8.

12. Do NOT loosenthe factory installed nuts already

on the terminal. Tighten nutswith 3/8' nut driver

for proper electricalconnection,

13. Tighten the lockingring and clamping screwsof

the conduitconnector.

14, Replacethe terminal blockcover,

Page3