3.3: SET UP OF FORK

Tools Required: Good Quality Shock Pump

Small Ruler

IMPORTANT SAFETY NOTE: Always stop riding when making adjustments of any kind to the bicycle!

The front suspension fork fitted to your Whyte bike will be pre-set with the standard settings. Before riding, you may need to

adjust these setting. First is the Sag setting on the fork. This is to ensure the forks are set-up correctly for your own body

weight, so the fork will perform as intended.

To set Sag on the front fork, you need to measure the amount the fork compresses when you sit on the bike in the normal rid-

ing position. See the table for our recommendation of front fork sag on your Whyte bike. To achieve this you will need to adjust

the air spring pressure inside the fork.

Refer to the specification table in this manual, and then to the relevant fork manufacturers set up instructions to find how to

adjust the air spring pressure in the fork. Using a shock pump, either add or remove air until Sag is correctly set.

Please note that for the detailed instructions for servicing and all matters relating to the forks fitted to your Whyte bike, please

refer to the manufacturers instructions.

Rebound Damping adjustment:

This adjustment fine-tunes the speed at which the wheel returns to its normal ride height after hitting a bump. Refer to the

relevant manufacturers instructions to find out how to adjust the rebound damping. To demonstrate the effect of this function,

turn the adjuster to its slowest setting. Press down on the handlebars to compress the forks, then release the load. The

suspension recovers very slowly to its original position.

Repeat the above with the adjuster turned to the fastest setting and the difference will be seen immediately the load is

released. We recommend the optimum setting is to adjust the re-bound damping to be as slow as possible, but not so slow that

the normal ride height is not recovered. On very rough terrain, if the bike becomes progressively lower as more bumps are hit

then the re-bound damping is set too slow. On the other hand if the bike feels choppy and not plush then the re-bound

damping is too fast. A bit of trial and error is needed to get the exact setting.

3.4: SET UP OF REAR DAMPER

Tools Required: Good Quality Shock Pump.

Small Ruler

IMPORTANT SAFETY NOTE: Always stop riding when making adjustments of any kind to the bicycle!

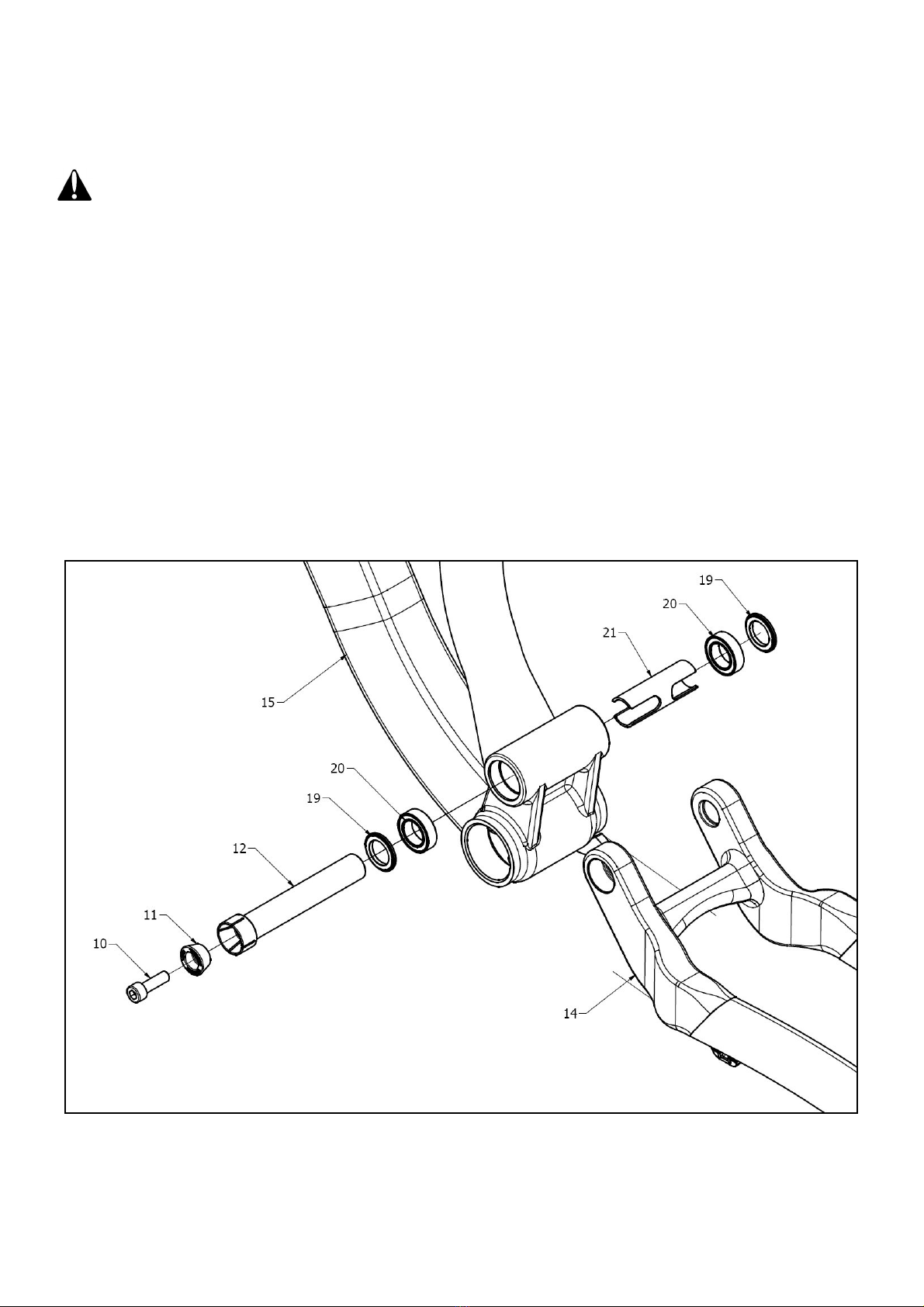

Your Whyte bike is fitted with an air spring rear shock absorber. This means that the air pressure in the shock absorber

determines the spring rate. The correct ‘sag’ can be found using the sliding ‘O’ ring fitted to the shaft of the shock piston. Slide

the ‘O’ ring against the shock body. Then gently sit on the bike in your normal riding position and with normal riding gear,

including back pack if applicable, and also raise your feet off the floor. Carefully dismount and measure the distance the ‘O’ ring

has moved away from the shock body.

The optimum distance for the Quad-Link rear suspension system is shown in the table. If there is less than that distance fit a

shock pump and release air pressure. Conversely if there is greater than that distance, fit the shock pump and increase air.

Repeat the ‘sag’ test until the recommended sag distance is achieved.

Rear Suspension Set-up - Rebound Damping:

When the damper unit is being compressed, this is known as the compression stroke. As the suspension unit recovers from

compression back towards its full length, this is called the re-bound stroke. All the shocks fitted as standard to the Whyte full

suspension mountain bikes have factory set compression damping, and manually adjustable rebound damping.