CAUTIO

Whilst fitting these mudguards:

• Confirm they are large enough for the tyres fitted to your bicy-

cle. 38mm” mudguards are suitable for Whyte Cambridge,

Cambridge Varsity, Carnaby, Charing Cross, Cornwall, Devon,

Dorset, Kings Cross, Pimlico, Portobello, Shoreditch, Somerset,

Stirling, Suffolk, Sussex, Victoria & Whitechapel models (Rigid

forks). 46mm” mudguards are suitable for Whyte Caledonian,

Chiltern, Coniston, Malvern & Ridgeway models (Suspension

Forks) and Fairfield (Rigid forks). The Montpellier & Stowe

models have no suitable mounting points for mudguards.

• Check that there will be at least 6mm clearance around the

tyre when they are fitted correctly.

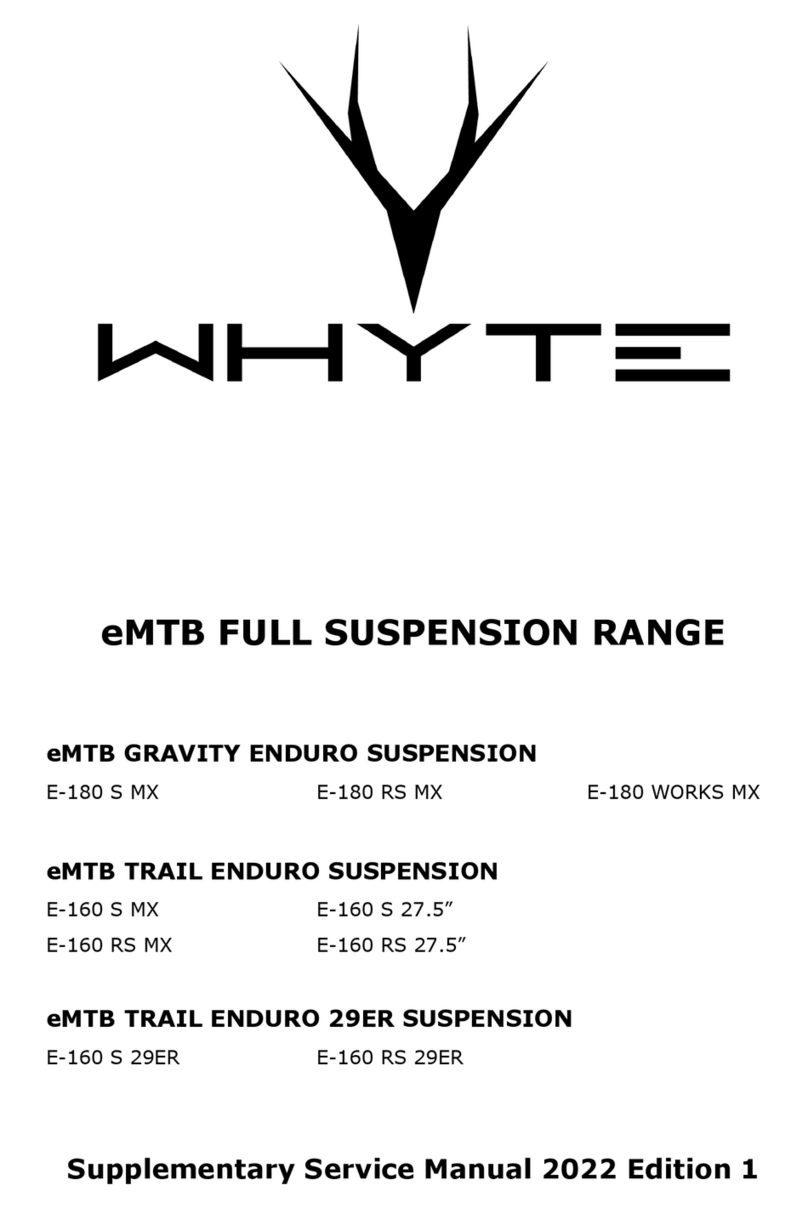

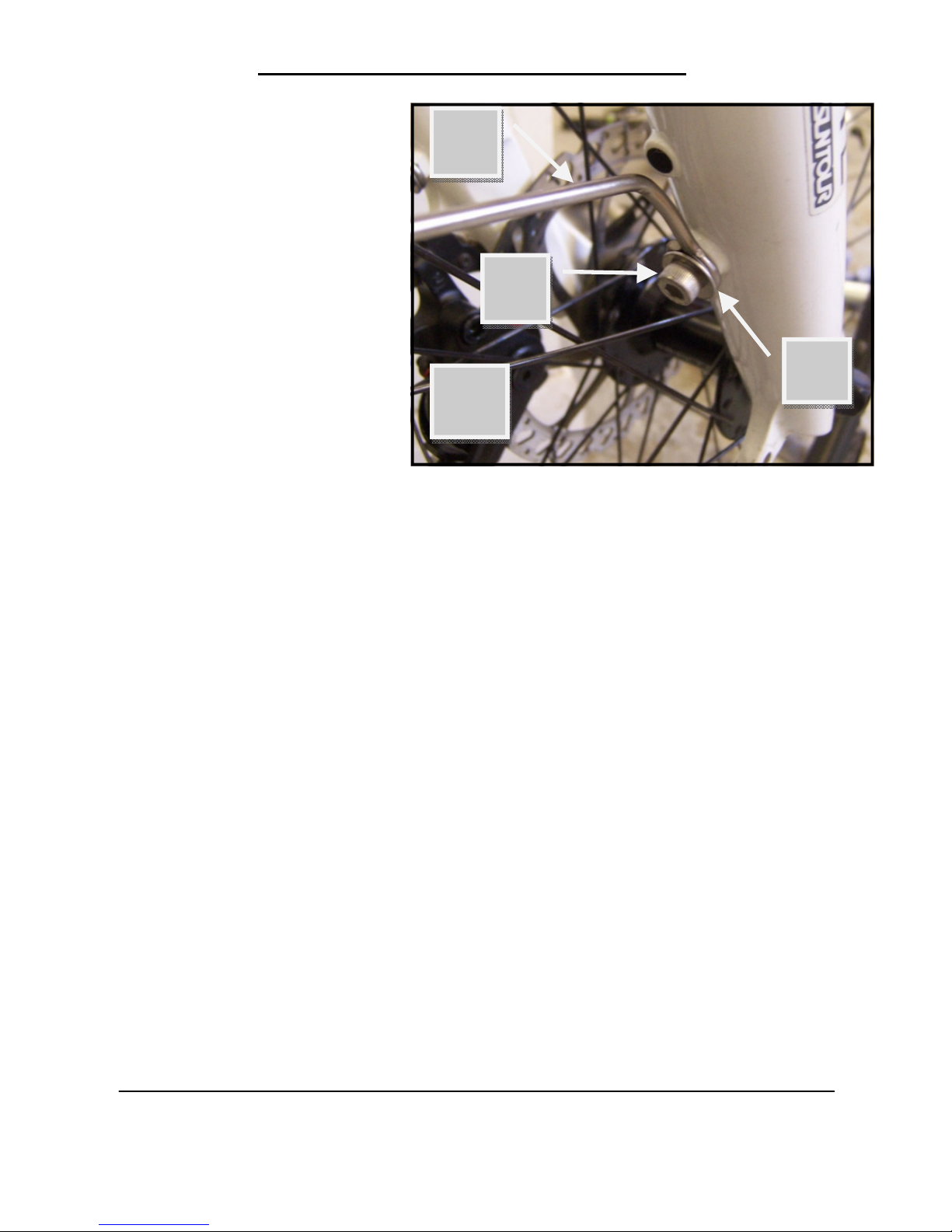

• It is recommended to apply Loctite 243 Thread-Locker or simi-

lar thread adhesive to the threads of all screws that hold the

stays to either the fork or frame. This will help to ensure they

will not come loose. Carefully follow Loctite’s own assembly

instructions.

• SAFETY CHECK – CO FIRM THE CORRECT OPERATIO OF

THE BRAKES A D GEARS AFTER FITTI G THE MUD-

GUARDS. If in doubt either consult the manufacturer’s user

instructions or contact your Whyte Bikes dealer.

Before each and every ride:

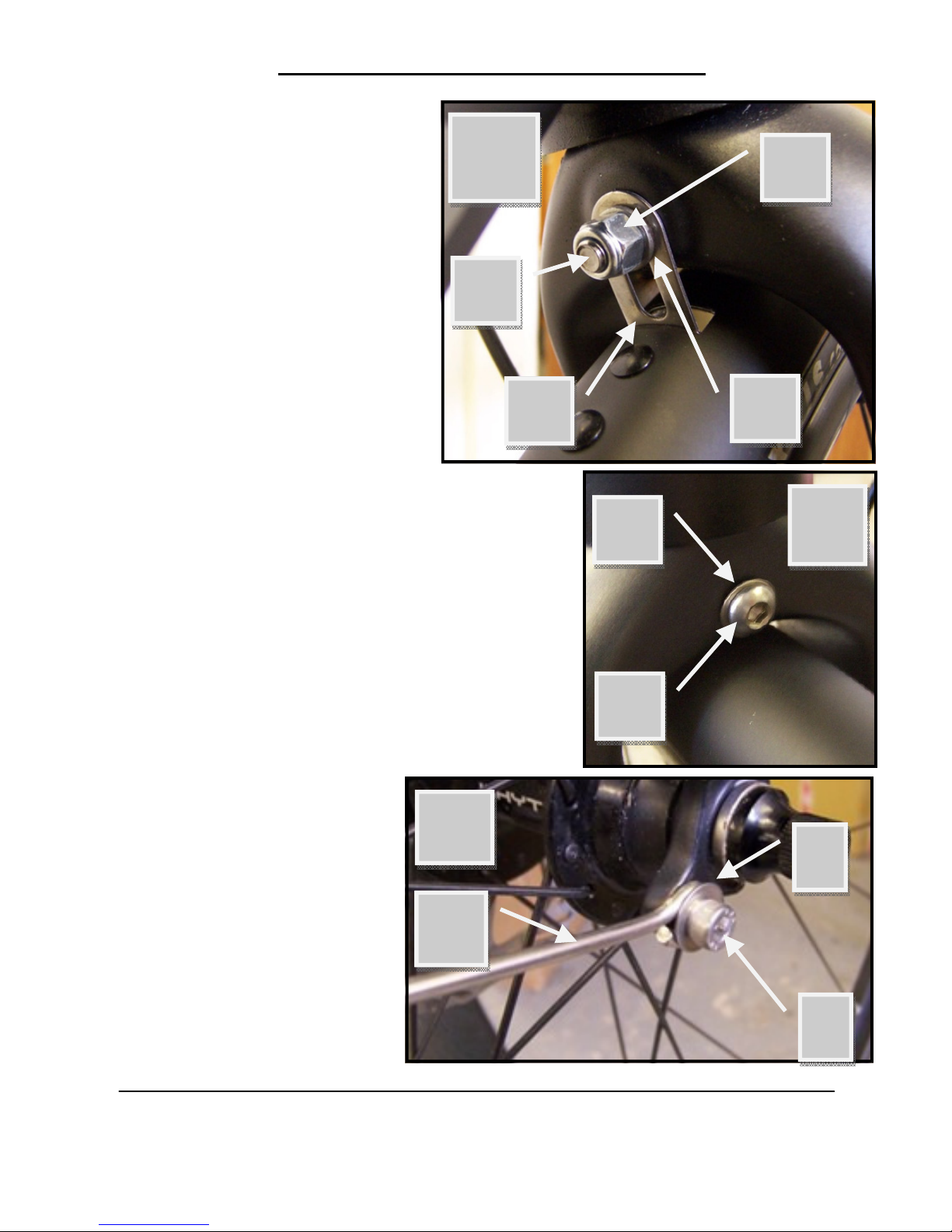

• Check that all the fasteners holding the mudguards in place are

still tight.

• If necessary, clean and dirt or road debris from the inside of

the mudguard, since this will reduce the clearance to the tyre.