WWW.WIDDDERTOOLS.COM®7

(203) 777-5395

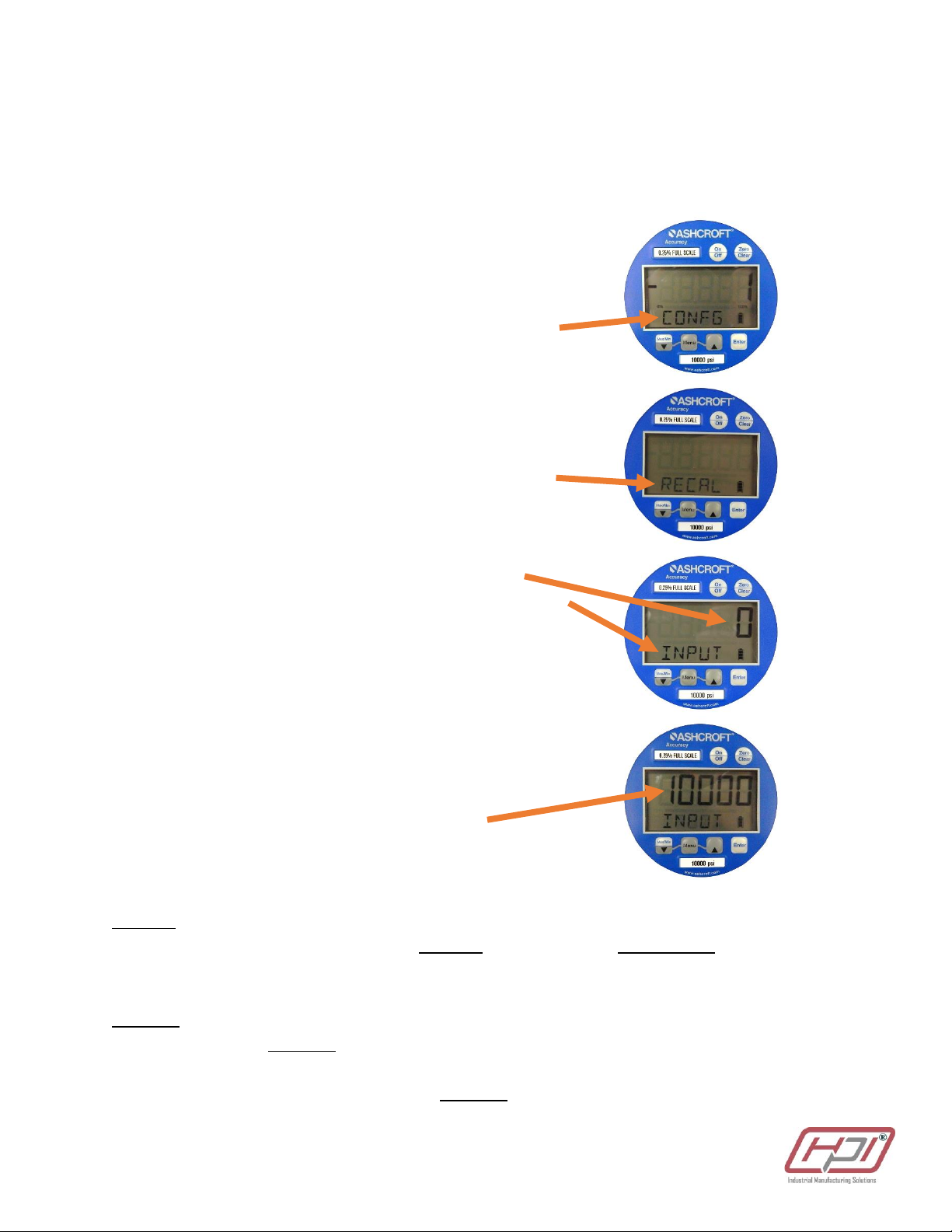

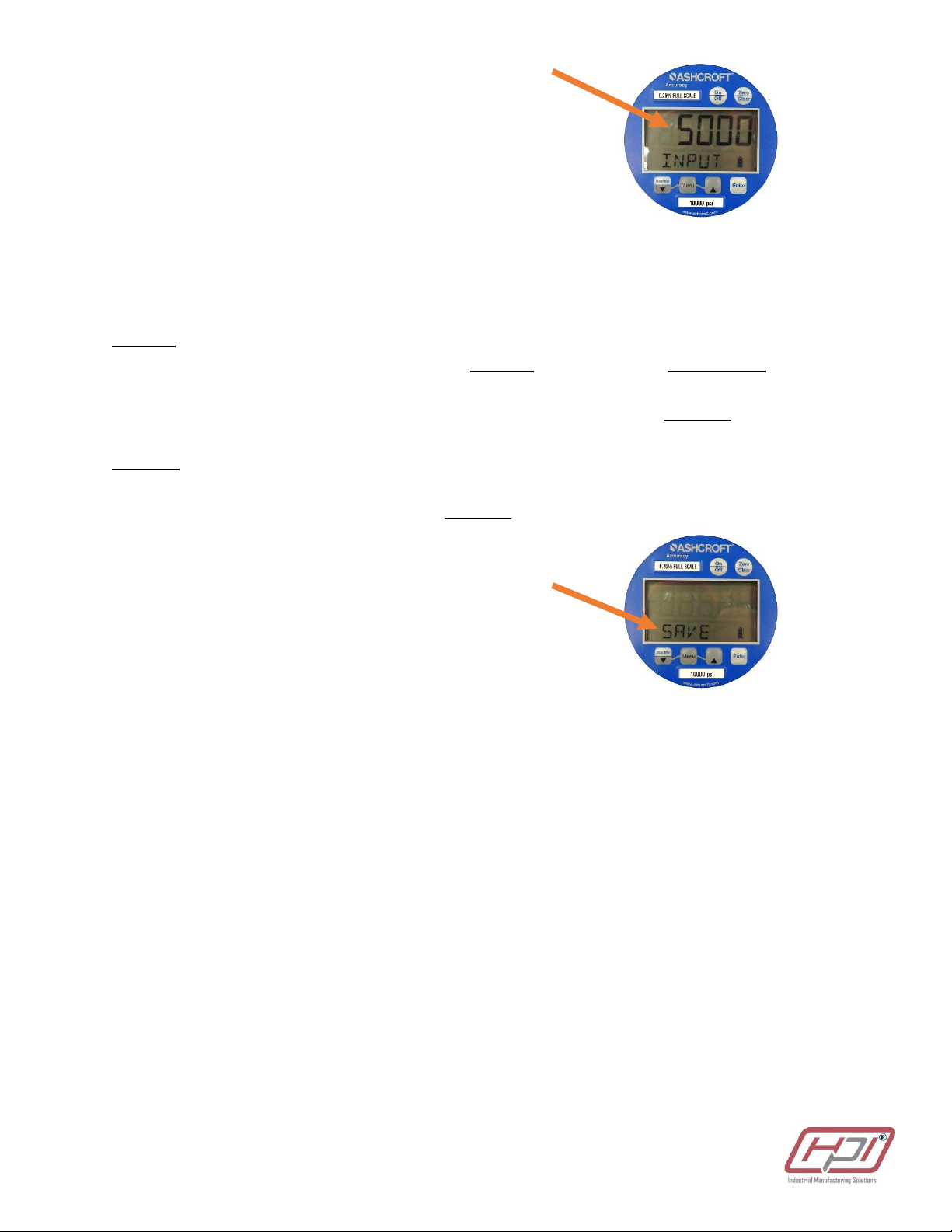

17. The HPIC unit gauge will now display 5000 on the top line

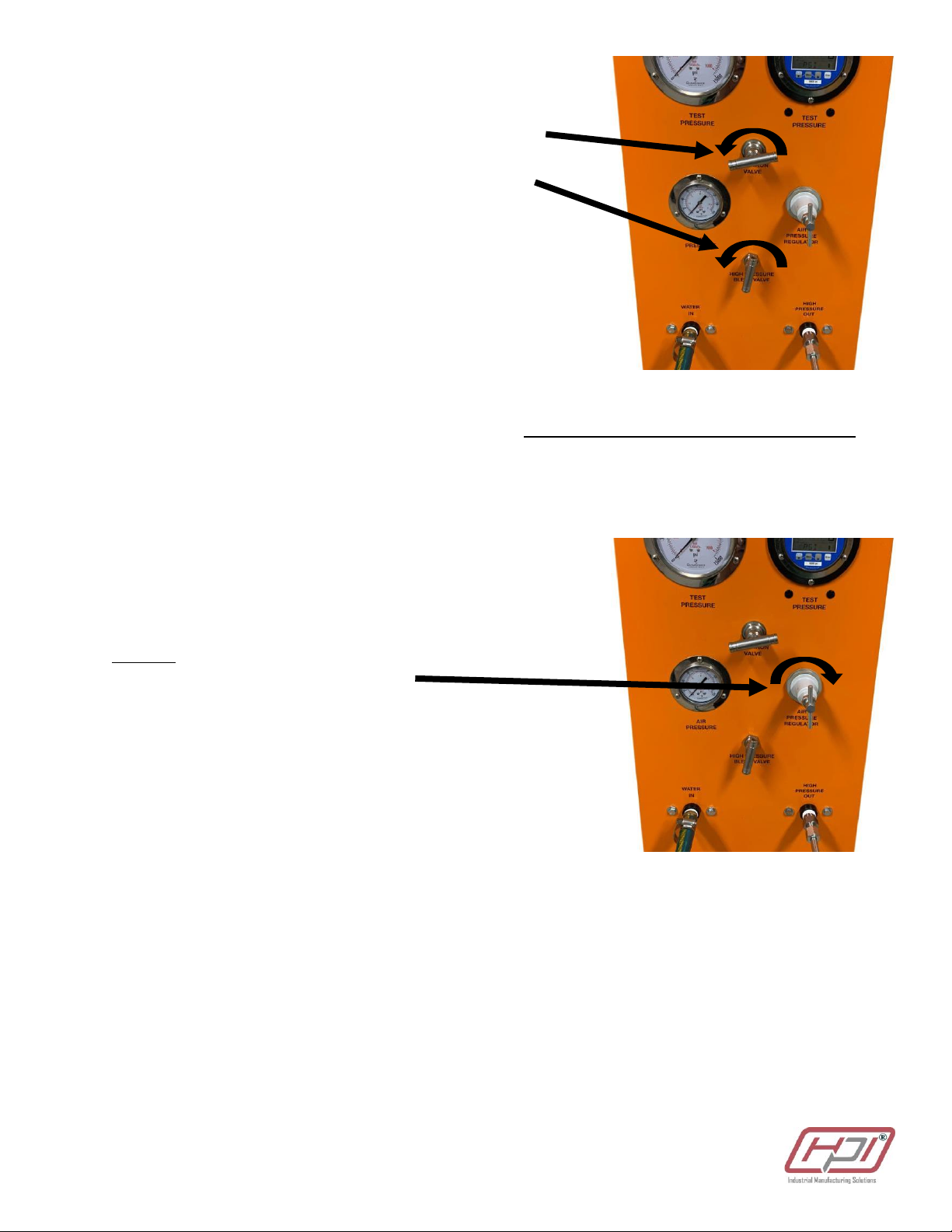

18. Back off the Air Regulator all the way (counter-clockwise)

19. Back off the Fine Adjustment Knob all the way (counter-clockwise)

then rotate 1 full turn clockwise

20. Open the bleed valve on HPIC Unit to relieve all pressure in the system

21. Close the Bleed Valve

22. SLOWLY increase the system pressure to about 4900 psi

Again, it is very important that the pressure be SLOWLY increased and to NOT EXCEED 5000 psi

23. From 4900 psi use the Fine Adjustment Knob to increase the pressure to EXACTLY 5000 psi (again, give

the system a few seconds to settle and perform and fine adjustments needed to get the system to

EXACTLY 5000 psi)

24. Be sure the Calibration System gauge reads EXACTLY 5000 psi and press ENTER on the HPIC unit gauge

(the mid-scale pressure point is now set)

25. The word SAVE will appear on the HPIC Unit gauge screen

26. Press ENTER to finalize the calibration process

27. Continue to Disconnecting HPIC Unit

F. Disconnecting HPIC Unit

1. Back off the Air Regulator all the way (counter-clockwise)

2. Disconnect the air supply line from the HPIC Unit

3. Turn off the water supply and open the Bleed Valve to relieve all pressure in the system

4. Disconnect the water supply from HPIC Unit

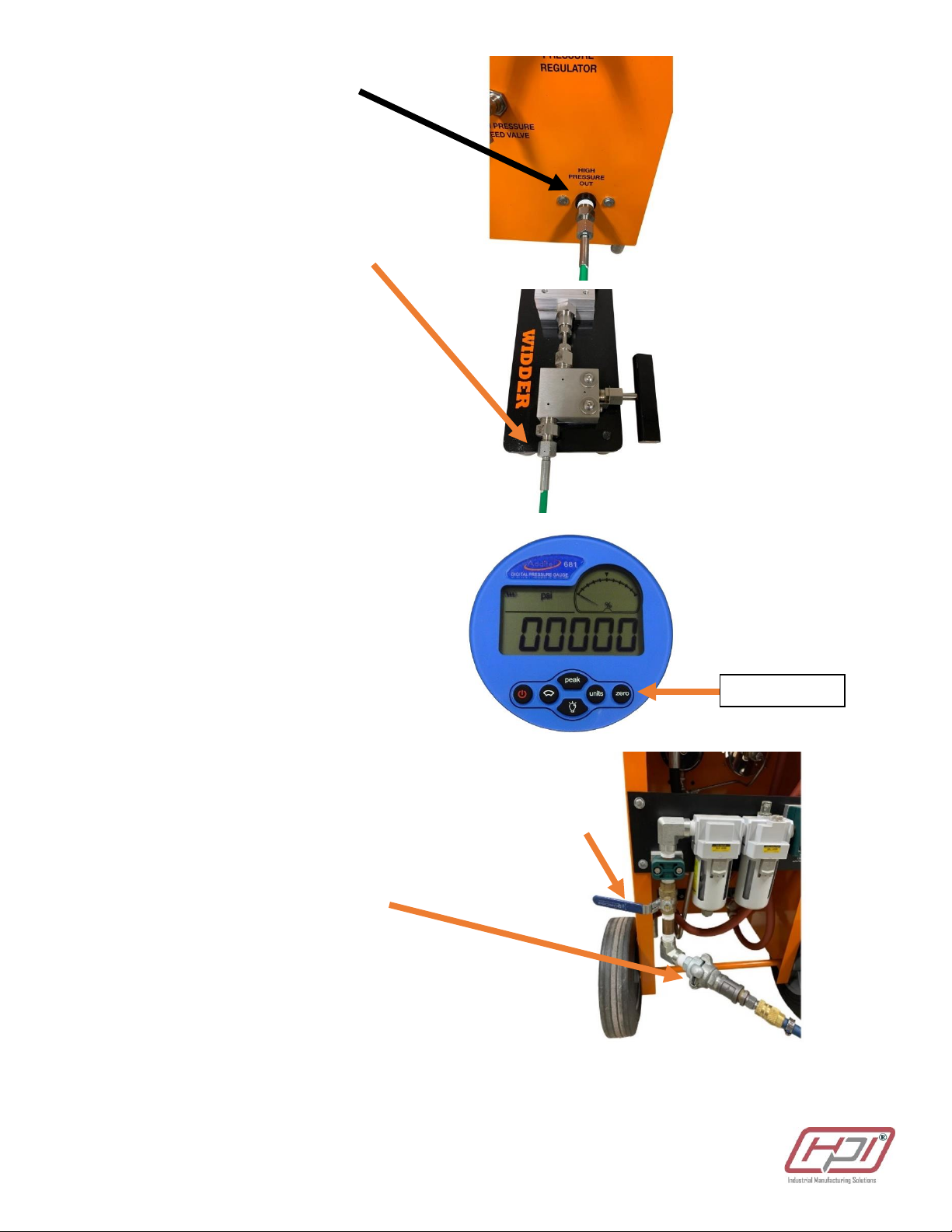

5. Using two wrenches disconnect the green hose from the outlet adapter in HPIC Unit

6. Remove the adapter from the OUTLET

7. If performing tests on multiple units it is acceptable to leave green hose attached to Calibration System

8. If needed, remove the green hose from the Calibration System with two wrenches (making sure the

adapter on the Calibration System does not spin)