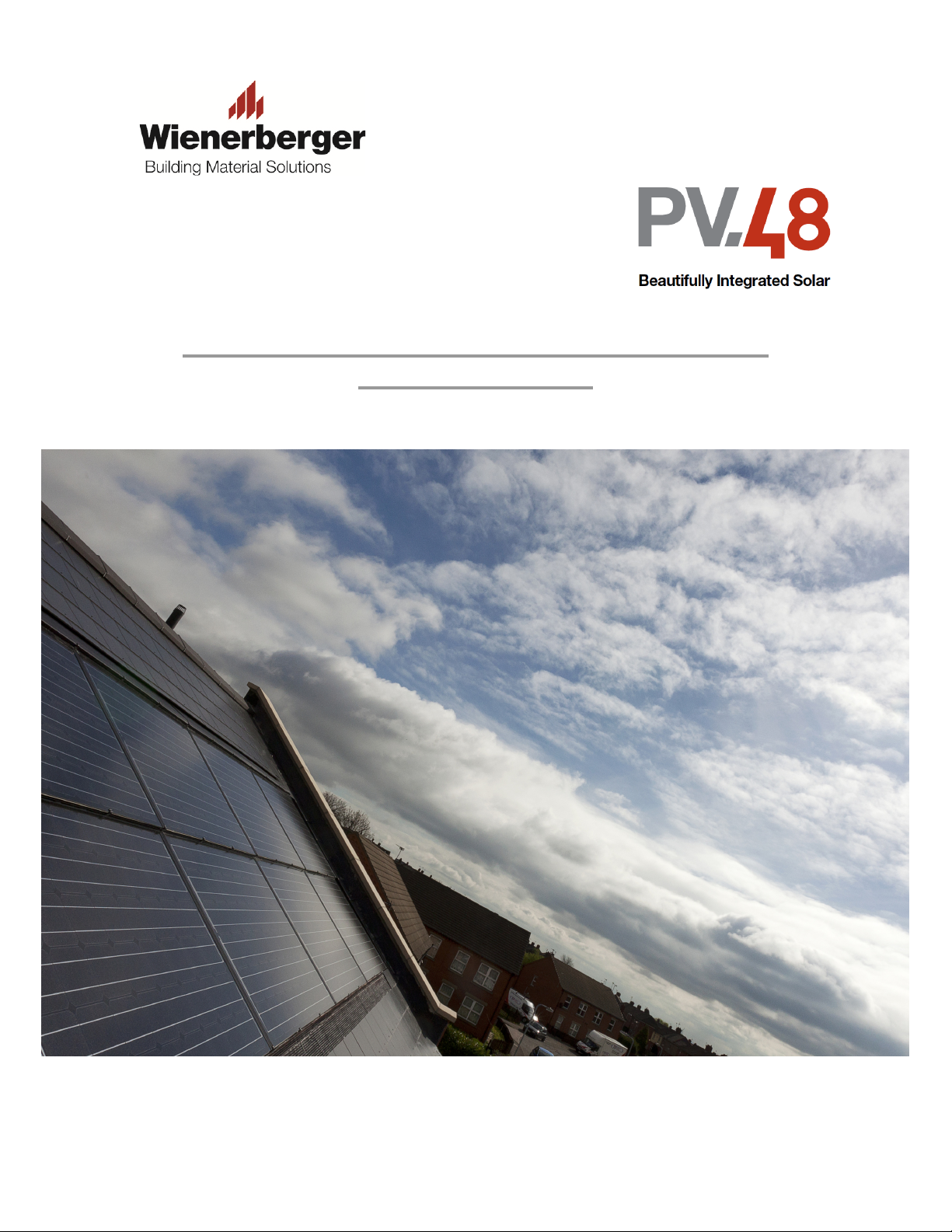

Wienerberger PV48 User manual

Sandtoft PV48 Solar System – Step By Step

Installation Guide

**PLEASE READ THESE INSTRUCTIONS CAREFULLY**

2

Health and Safety Guidance Notes

General

General construction site training must be followed

Ensure safe working at heights practice is adhered to

Manual handling safe practice should be followed at all times

All health and safety regulations must be adhered to at all times

Avoid installing the system in severe adverse weather conditions

All roof work to be in accordance with British Standard 5534

Follow the installation guide to ensure a weather tight finish

Electrical Hazards

Extreme care must be taken not to cut or damage any cable during

installation

Solar Panels produce a DC voltage whenever they are exposed to light. DC

voltage generated from the solar panels cannot be switched off.

The solar panels are fitted with un-exposed connectors to prevent accidental

electrical shock during general handling

All aspects of any installation MUST be carried out without connection to the

mains supply

Ensure all connectors are protected from the weather at all times and that they

are clean and dry.

3

Installation Preparation

Follow the installation guide

Store the solar panels in a safe and weatherproof environment

Use two people to carry the panels by supporting both the underside and side

edge, or where possible use suction lifters where practical

Ensure that any uninstalled solar panels are protected from wind to avoid

damage

The solar panels have a tempered glass surface, and although this is strong,

avoid walking on, or dropping any tools or materials onto the surface as this may

cause the glass to shatter.

Remember to

Work Safely

Wear all relevant Personal Protective Equipment

Keep the work area free from trip and fall hazards

Use correct manual handling methods

Plan your work correctly to avoid accidents

Work in a clean and tidy environment

Sandtoft’s installation guide has been written with the roofer in mind

Done correctly, it will allow the installer to ‘set out’ for the panels, fit the flashing

kit and tile around the designated area before fitting the solar panels.

This will give the installer somewhere to stand (in the battens), thus avoiding the

need to work over or around installed panels.

4

Component Checklist

Please check that you have the following items and leaflets in order to complete

the installation:

Component Pack

Solar Panels Ventilation Strip

Solar panel fixing brackets Side Flashing Interlock fillers 70mm Screws

Fixing Bracket spacers Side Flashing fixing clips 45 mm Screws

Sikaflex sealant Koraflex 30mm Screws

Connection cables Flashing Kit 20mm Screws

Expanding Foam strips (for profiled tiles only) Wiring Diagram

In addition you may also have an electrical pack from Sandtoft.

5

Starter Kit

Sandtoft PV48 Template

Volt meter

9 Volt battery

Suction Lifter

Tools for the job

Bull nosed pliers Lead dresser Tape measure

String line Power drill

Stanley knife Glue gun

6

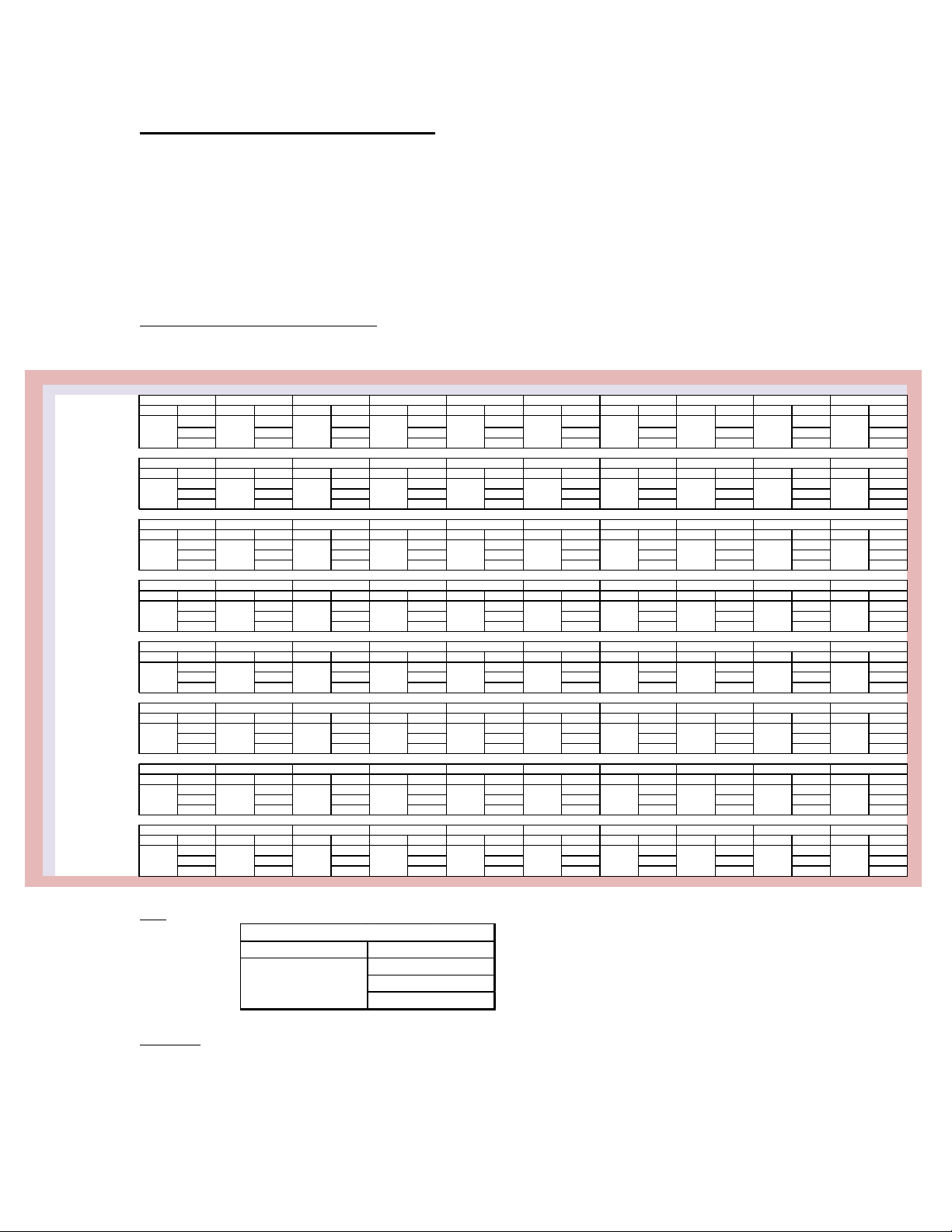

Counter batten length

number required / total x6 7 x9 10 x12 14 x15 17 x18 20 x21 27 x24 27 x27 31 x30 34 x33 37

Support Battens (m) 4 7 9 12 15 18 20 23 26 29

In-Fill Battens (m) 2 5 7 9 12 14 17 19 21 24

Total (m) 13 21 30 38 47 59 64 73 81 90

Counter batten length

number required / total x6 13 x9 19 x12 26 x15 32 x18 38 x21 45 x24 51 x27 57 x30 64 x33 70

Support Battens (m) 4 7 9 12 15 18 20 23 26 29

In-Fill Battens (m) 2 5 7 9 12 14 17 19 21 24

Total (m) 19 30 42 53 65 76 88 99 111 122

Counter batten length

number required / total x6 19 x9 28 x12 37 x15 47 x18 56 x21 65 x24 75 x27 84 x30 93 x33 103

Support Battens (m) 4 7 9 12 15 18 20 23 26 29

In-Fill Battens (m) 2 5 7 9 12 14 17 19 21 24

Total (m) 25 39 54 68 83 97 112 126 141 155

Counter batten length

number required / total x6 25 x9 37 x12 49 x15 62 x18 74 x21 86 x24 99 x27 111 x30 123 x33 135

Support Battens (m) 4 7 9 12 15 18 20 23 26 29

In-Fill Battens (m) 2 5 7 9 12 14 17 19 21 24

Total (m) 31 48 66 83 100 118 135 153 170 188

Counter batten length

number required / total x6 31 x9 46 x12 61 x15 76 x18 92 x21 107 x24 122 x27 138 x30 153 x33 168

Support Battens (m) 4 7 9 12 15 18 20 23 26 29

In-Fill Battens (m) 2 5 7 9 12 14 17 19 21 24

Total (m) 37 57 77 98 118 139 159 180 200 220

Counter batten length

number required / total x6 37 x9 55 x12 74 x15 92 x18 110 x21 128 x24 147 x27 165 x30 183 x33 201

Support Battens (m) 4 7 9 12 15 15 15 23 26 29

In-Fill Battens (m) 2 5 7 9 12 12 12 19 21 24

Total (m) 43 66 90 113 137 155 174 207 230 253

Counter batten length

number required / total x6 43 x9 64 x12 85 x15 107 x18 128 x21 149 x24 170 x27 192 x30 213 x33 234

Support Battens (m) 4 7 9 12 15 15 15 23 26 29

In-Fill Battens (m) 2 5 7 9 12 12 12 19 21 24

Total (m) 49 75 101 128 155 176 197 234 260 286

Counter batten length

number required / total x6 49 x9 73 x12 97 x15 121 x18 146 x21 170 x24 194 x27 218 x30 242 x33 267

Support Battens (m) 4 7 9 12 15 15 15 23 26 29

In-Fill Battens (m) 2 5 7 9 12 12 12 19 21 24

Total (m) 55 84 113 142 173 197 221 260 289 319

4321

5095mm5095mm5095mm

5

98765

8

7075

7

6085mm6085mm

6

5095mm 5095mm 5095mm

4105mm

5095mm 5095mm 5095mm 5095mm

4105mm 4105mm4105mm 4105mm 4105mm 4105mm

4

4105mm 4105mm

7075

8065 8065

4105mm

3115mm 3115mm 3115mm 3115mm 3115mm 3115mm

2125mm 2125mm 2125mm 2125mm

3

3115mm 3115mm 3115mm 3115mm

1135mm 1135mm

2

2125mm 2125mm 2125mm 2125mm 2125mm 2125mm

10

1

1135mm 1135mm 1135mm 1135mm 1135mm 1135mm 1135mm 1135mm

Number of panels - Horizontal

6085mm 6085mm 6085mm 6085mm6085mm 6085mm 6085mm 6085mm

7075 7075 70757075 7075 7075 7075

Number of panels -Vertical

8065 8065 8065 80658065 8065 8065 8065

7075

in-fill batten total

Total (m)

Length of counter batten (mm)

number required counter batten total

support batten total

Positioning the Solar Panel Array

For best visual effect, it may be necessary to position the panel array with equal

distance from eave to ridge, and centrally from verge to verge. Use the counter

batten table overleaf to calculate the vertical height of the array. Use the sum of

fitted solar panel widths plus one overall panel width for the total width of the

array. E.g. for a three panel wide system the sum is 1377mm + 1377mm +

1394mm = 4148mm.

Counter batten requirements

Key

Example

If you have 3 vertical panels and 3 horizontal panels, you will need 12 x 3115mm counter battens,

(37.38m of batten in total).

The vertical height of the array is 3115mm

The total width of the array is 4148mm.

7

Visual Guide to the use of the Sandtoft PV48 template

8

Preparing the roof

Firstly prepare the area where the solar panels are to be fitted. This may involve

stripping off the existing roof covering, if this is the case, the existing tiles may

need to be lowered to ground level, stacking some aside for re-use as required.

In order to counteract wind uplift the existing battens in the area where the panels

are to be fitted must be screwed to the rafters. Use the 70mm screws provided.

If installing a new roof, batten out the roof as usual, and screw to the rafters as

previously stated.

Additional battens need to be fitted to support the solar panel’s front apron

flashing and counter battens are needed to support the solar panels.

The first additional batten is fitted 100 -150mm above the tile batten (depending

on tile profile). A second batten is fixed directly above it. Use a chalk line to

ensure the batten is perfectly parallel with the tile batten.

Fix these battens to the rafters with 70mm screws.

9

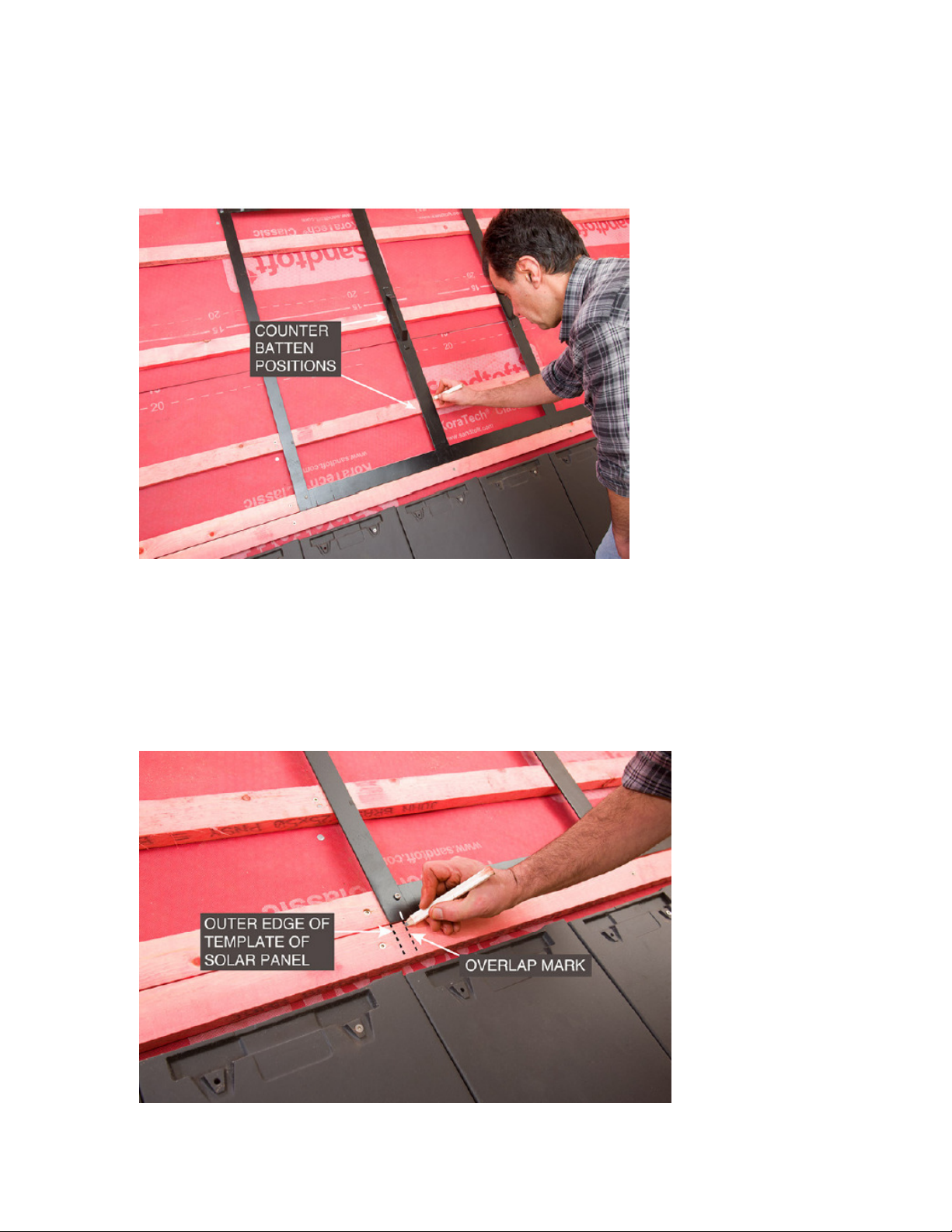

Marking out the Counter battens

Position the template at the bottom right hand corner of the designated solar

panel area. Lay the template onto the battens to enable you to mark where the

counter battens will be fitted. See photo below.

Installation tip: screw the template to the top batten to help keep the template in

position and perfectly square while you mark the edge of the template.

Mark the batten at the bottom of the template where the edge of the template

ends. This represents the junction between the flashing and the panel.

Make a second mark on the batten at the bottom of the template 50mm (counter

batten position) in and make a third at 50mm (counter batten position)

10

Mark the counter batten positions onto all the battens where the template's cross

bars lay across them. Mark both left and right hand edges of the template’s cross

bars.

At the left hand corner of the template mark the outside edge of the template

which indicates the outer edge of the solar panel.

Make a second mark which indicates the overlap of the adjacent solar panel.

11

Now moving up the template - make a mark only where the inside edge of the

template cross bar rests on the batten. This indicates the inside right edge of the

counter batten.

THE ACCURACY OF THIS MARK IS CRUCIAL TO THE INTEGRITY OF THE

INSTALLATION - AS IT ENSURES THAT THE FIXING BRACKET IS

POSITIONED CENTRALLY ON THE COUNTER BATTEN.

12

Move the template across to the left.

Position the bottom right hand edge of the template with the overlap mark you

have made on the batten (not the outer edge mark). Screw the template to the

battens for continued accuracy. Do not mark for counter battens at this corner.

Mark on all the battens where the template cross bars lay across them, both at

the left and right hand edges of the template’s cross bars. This indicates where

the counter battens are to be positioned.

Only ever mark the outer edge of the template if this coincides with the outer

edge of the designated panel area. Otherwise mark the inside counter batten

line as previously stated.

13

Note: These instructions are based on a 2 x 2 panel configuration, and so

this point is the bottom left hand corner of the solar panel array. IF YOUR

ARRAY IS WIDER THAN 2 PANELS PLEASE REPEAT AS PER PREVIOUS

PAGE FOR EACH ADDITIONAL PANEL.

At the bottom left hand corner of the designated panel area:

At the bottom left hand corner, mark the outside left hand edge of the template

Mark the batten (50mm) from the outer edge and make another mark (50mm).

These marks represent the counter batten positions for the left hand side of the

designated panel area.

Also mark the left hand outer edge of the template where the template's cross

bars lay across the battens.

14

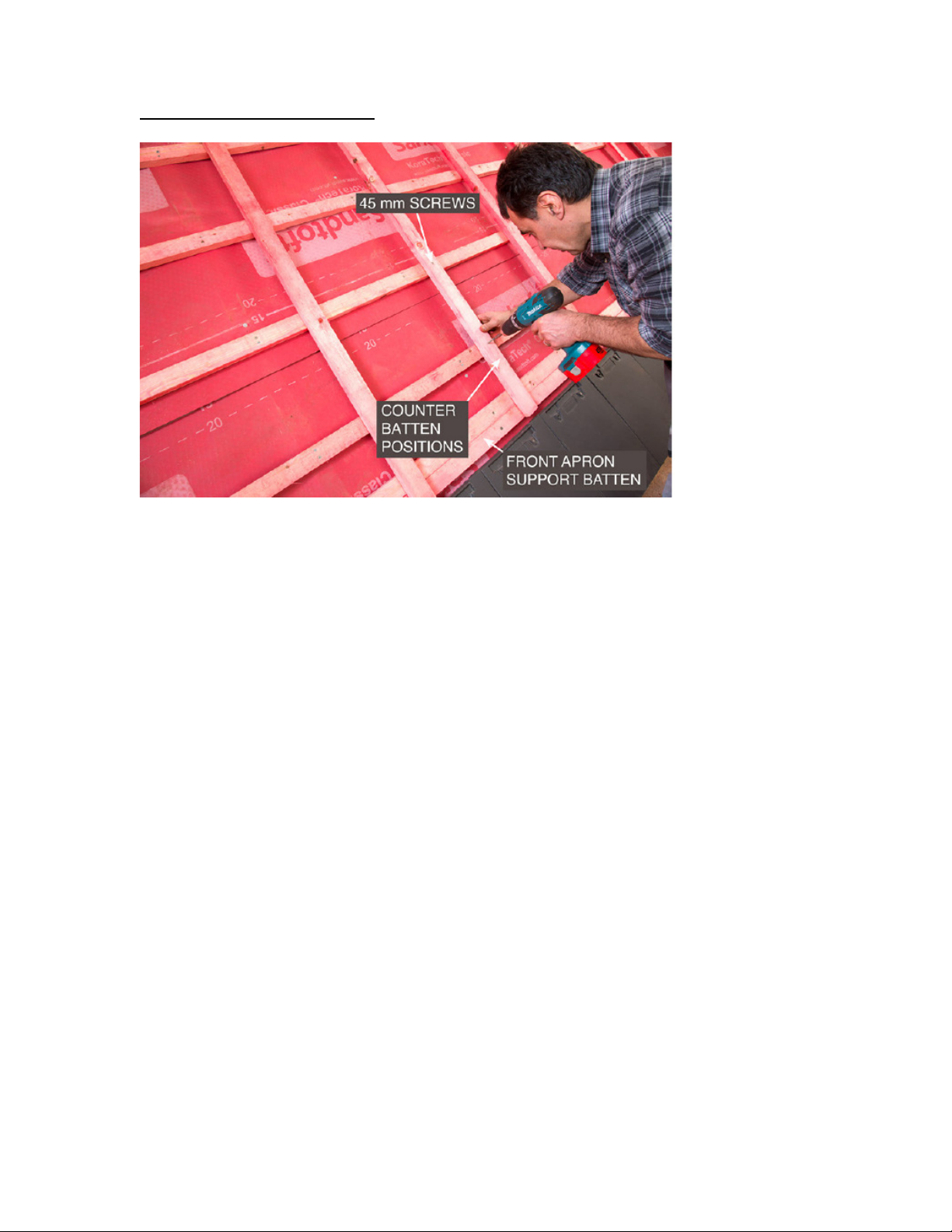

Fitting the counter battens

Position the bottom of the counter batten to line up with the bottom of the front

apron support batten. Fix the counter batten to the battens with 45mm screws, for

the height of the template only. Do not continue up the roof at this stage.

Fit a second counter batten adjacent to, and on the inside of, the first counter

batten. This will carry the fixing bracket fixings for the solar panel. This

configuration of two battens is required only at the outside edges of the

designated panel area. Screw the second counter batten to the battens for the

height of the template only.

Continue to fit counter battens to the roof to match the markings made on the

battens.

Screw all counter battens to the battens in the area of the template only. This

allows for the re-alignment of the unsecured length of the counter battens at a

later stage.

Note: The counter battens need securing approximately every 300 - 400mm with

the 45mm screws provided

At the left hand edge of the designated panel area fit a final counter batten to the

outer marks.

Fit an additional counter batten to the inside of the final batten. This

configuration of two battens is required only at the outside edges of the

designated panel area. Screw the second counter batten to the battens for the

height of the template only. This additional counter batten will carry the fixing

bracket fixings for the outer left hand edge of the array of panels.

15

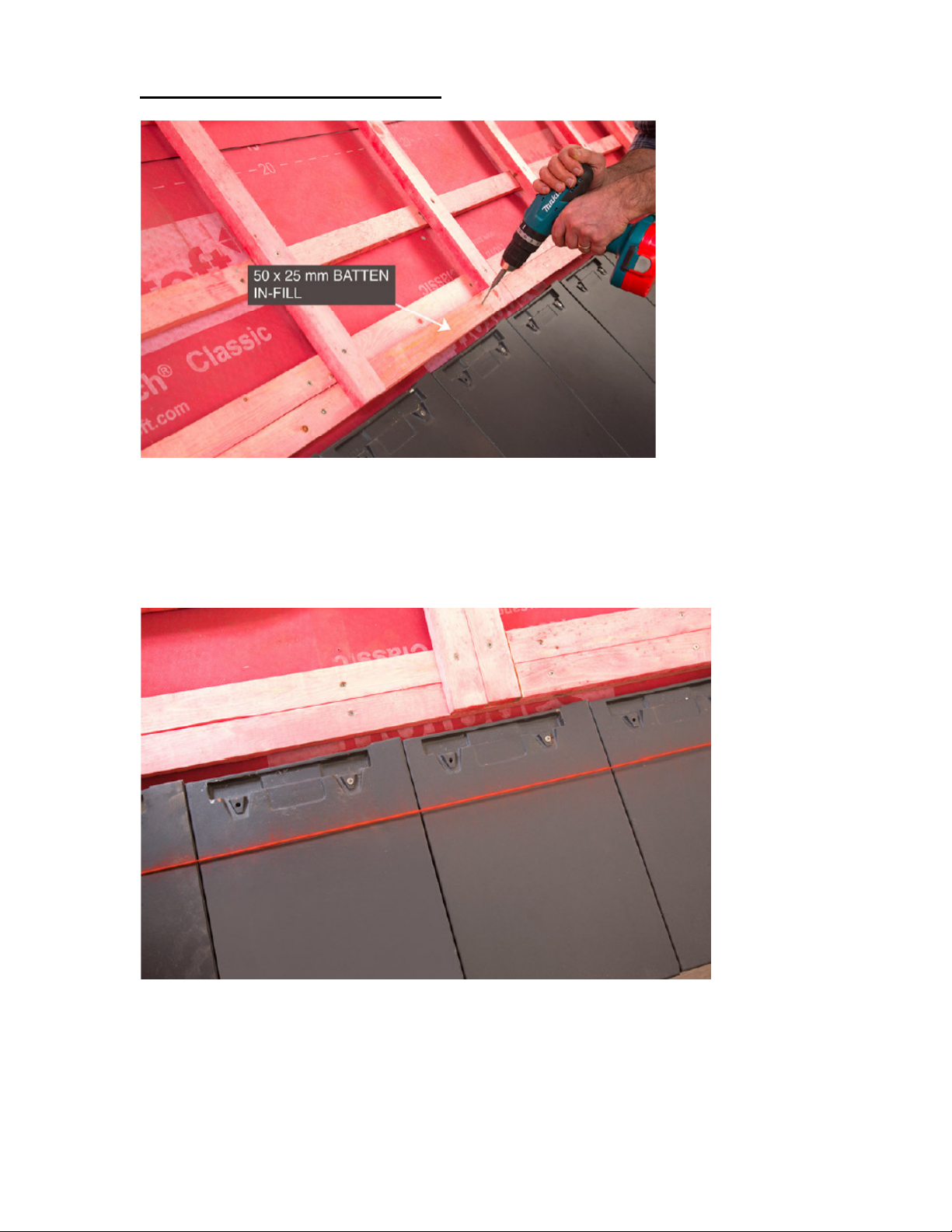

Preparing the front apron flashing

The gaps between the counter battens can now be in-filled. Use 50 x 25mm

battens cut to size and screw them into the battens. Use two fillers per gap. This

creates a support for the apron flashing which is to be created using Koraflex.

Note: Koraflex is an aluminium roll, fully coated with a butyl adhesive backing.

Strike a chalk line to mark the bottom of the apron flashing. Allow for a minimum

of 100mm cover over the head of the tile/slate. This leaves 220mm of Koraflex

to be dressed up over the front apron support battens.

16

Cut a piece of Koraflex 150mm wide and fit it at the bottom outside corner (not

pictured). Repeat the process at the bottom left hand corner. This will create a

double layer of Koraflex at the front corners for added protection..

Measure a length of Koraflex for the front apron so that it has a minimum side-lap

of 175mm at both the left and right hand sides.

This measurement allows for a 25mm upstand at the side of the counter batten

whilst maintaining a 150mm sidelap.

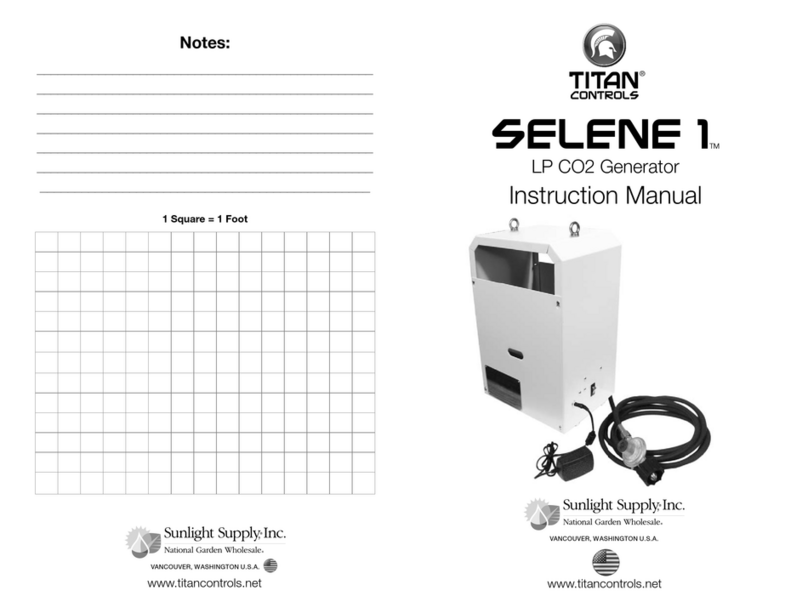

Secure the Koraflex onto each counter batten 40mm down from the top edge,

using 20mm galvanized clout nails. Dress the Koraflex firmly onto the tiles.

Tip: Use the square edge of a lead dresser to ensure that the upstand is clearly

visible.

17

After dressing the Koraflex, carefully remove the lower backing strip from the

Koraflex and dress into final position on the tiles.

Installing the Sandtoft ventilation strip

Measure down from an existing batten, mark both left and right and strike a line

between.

Position the Sandtoft ventilation strip over the Koraflex, ensuring correct

orientation. Fix with 20mm galvanized clout nails or 20mm screws through the

upper flat edge of the strip. See photo below. You may need to cut the final piece

of Ventilation strip to size.

Tip. Avoid fixing the screws where there is a counter batten as this may coincide

with a panel fixing bracket which will be fitted later

18

Use the template to check that the ventilation strip is at right angles to the

counterbattens.

Create a ‘welt’ by turning the top and side edges of the Koraflex flashing over,

this will stop any wind driven rain from entering the batten cavity.

Place the template in line with the extreme right side counter batten.

In the bottom left hand corner of the template, mark the outer edge and overlap

marks onto the ventilation strip. This indicates the position of the fixing bracket

which will later be located centrally between them.

19

Fit the fixing brackets with the spacers* in the configuration shown, centrally to

the counter battens, on top of the ventilation strip. Use the 30mm screws

supplied. Continue to fit the fixing brackets and spacers along the length of the

ventilation strip.

The butyl backing of the Koraflex will self-seal the screw holes.

* The fixing bracket spacer is supplied at size 140 mm however it is designed to

be used in two different lengths during the installation. The spacer is scored to

allow it to be broken into a shorter length piece of 80mm for use where specified

in this guide. See photo below.

The shorter length 80 mm spacers are to be used only at the bottom of the array

i.e. at the ventilation strip. Full length 140 mm spacers are used everywhere else

on the array.

Tip: Be careful to break the correct quantity of spacers

into short lengths 80mm. i.e. only those that will be required at

the ventilation strip at the bottom front edge of the array of

panels.

20

The photo below shows the fixing brackets and plastic spacers fixed to the

counter battens above the ventilation strip. The template is resting on the fixing

brackets in preparation for the fixing of the next row of fixing brackets.

Table of contents

Popular Inverter manuals by other brands

Scheppach

Scheppach SG1200 Translation from the original instruction manual

Giandel

Giandel PS-3000QBR user manual

Sunlight Supply

Sunlight Supply Titan Controls Selene 1 instruction manual

Kohler

Kohler 99EOZDJ installation instructions

Siemens

Siemens SINAMICS G120P manual

Cyber Power

Cyber Power CPS1000EILCD user manual

ring

ring PowerSourcePure Series instruction manual

Mitsubishi Electric

Mitsubishi Electric F700 instruction manual

Tripp Lite

Tripp Lite PV1000FC Features & specifications

Winco

Winco WL22000VE/A Installation and operator's manual

INHENERGY

INHENERGY HI-3K-SL user manual

Mastervolt

Mastervolt WHISPER 9.5 ULTRA installation manual