ii

Table of contents

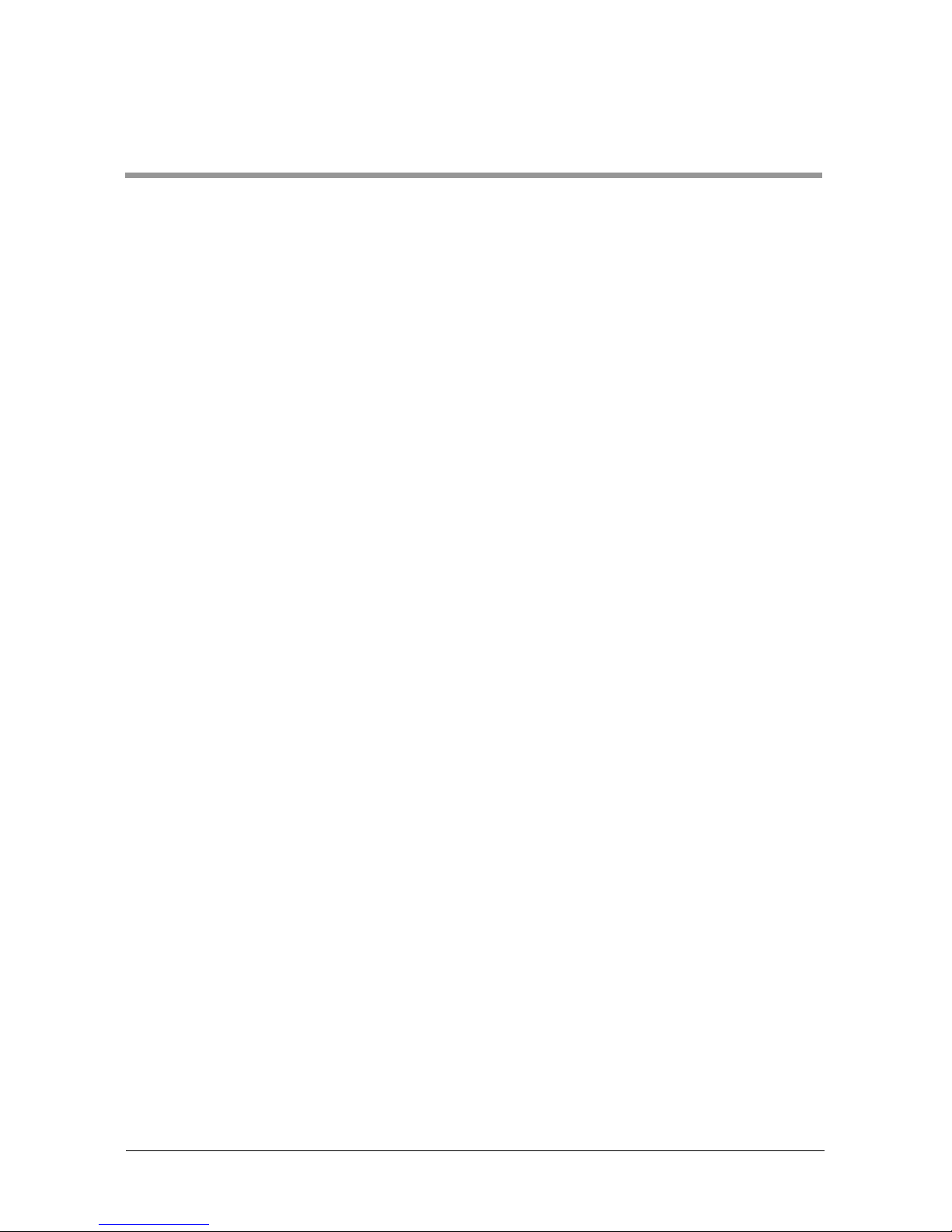

4.5 Setting Frequency with Operation Panel ................................ 51

4.6 Setting Forward/Reverse Run with Operation Panel ............... 52

4.7 Operating with Operation Panel ............................................... 54

5. Control Status Monitor..............................................................69

5.1 List of Control Status Monitor Items ...........................................70

5.2 Introduction of Monitor No ..........................................................72

6. Function Parameters ...............................................................81

6.1 Setting and Changing Function Parameters .............................. 82

6.2 Function Parameter List ............................................................. 86

7. Custom Mode ...........................................................................95

7.1 Allocating Parameter No............................................................. 96

7.2 Setting and Changing Parameters .............................................98

8. Setting Modes and Copy Functions of Built-in Memory ........101

8.1 Setting Modes and Copy Functions of Built-in Memory ........... 102

8.2 Setting Built-in Memory Parameters ....................................... 103

8.3 Parameter Upload Function (CPY1) ........................................ 105

9. Troubleshooting......................................................................113

9.1 Safety Precautions ............... ........................................ .......... 114

9.2 Abnormality Diagnostic Function and Resetting Method ......... 114

9.3 Handling Abnormalities .................... ....................................... 118

8.4 Parameter Download Function (CPY2) ................................... 107

8.5 Parameter Verification Function .............................................. 109

8.6 To Display or Conceal Built-in Memory Setting Mode ............. 111