WIKORA Wikosun 2010 User manual

© Wikora GmbH Page 1 Status: 27.04.2015

Errors excepted.

WIKORA GmbH

89568 Hermaringen

Phone: (07322) 9605-0

Fax: (07322) 9605-30

E-mail: contact@wikora.de

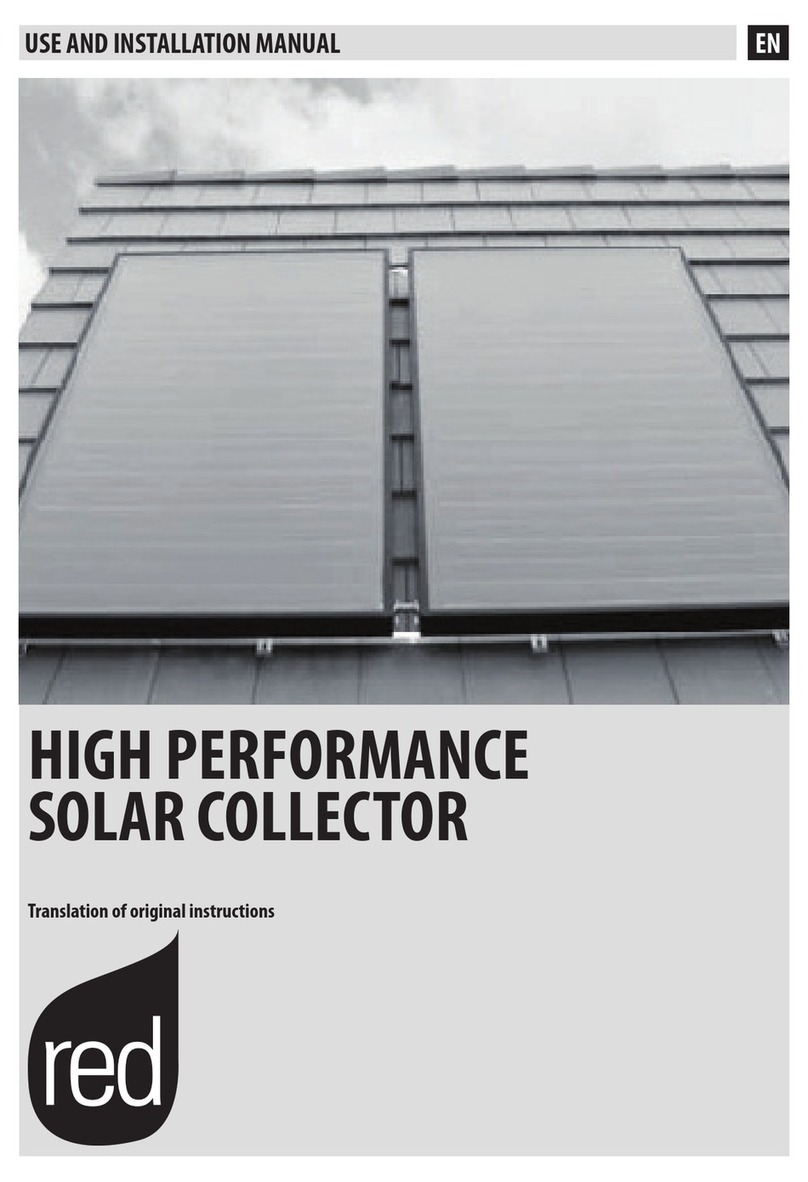

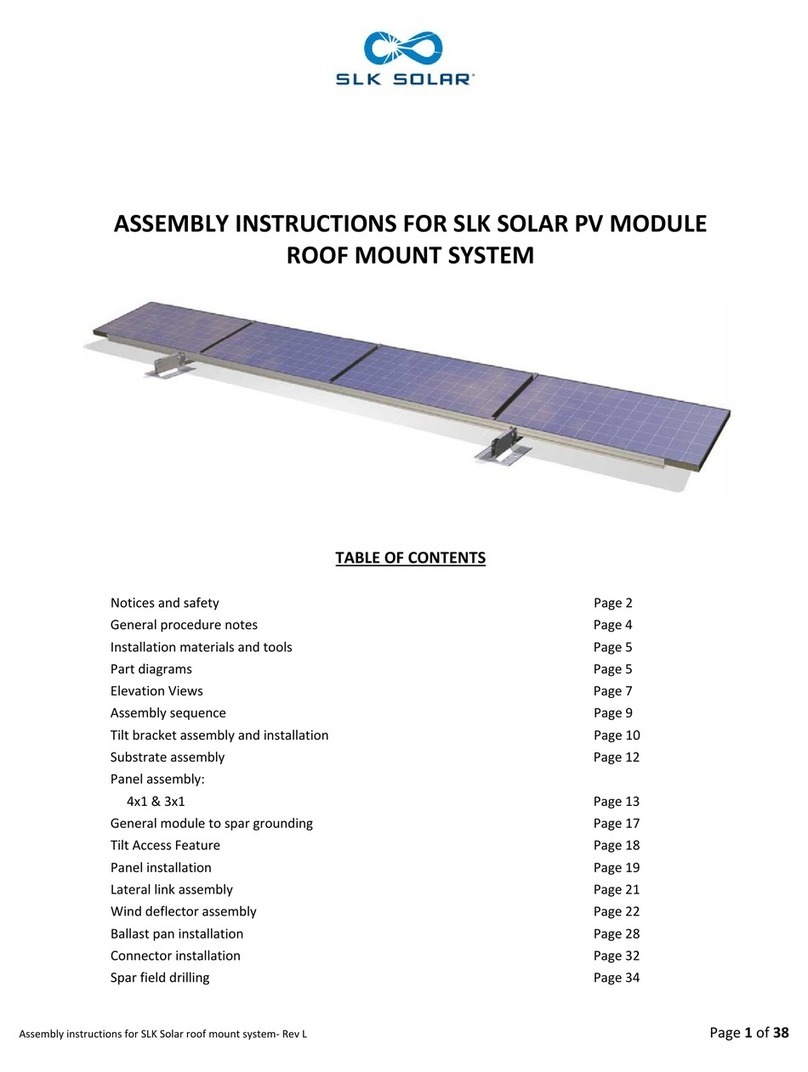

Installation manual

On roof mounting/

Flat roof mounting

Flat plate collectors

Wikosun 2010 / 2510

Installation and commissioning should be

undertaken by a specialist.

General terms and conditions of warranty state that

all installations must be performed by a suitably

trained and qualified plumber by taking into account

local norms and regulations.

Factory warranty will only be covered if the

installation instructions are followed.

Warranty does not cover any damages, caused by

non-observance of this manual.

The correct functioning is only guaranteed if the

installation instructions are followed.

The system is to be checked annually by a

specialized company. Independently, occurring

defects must be repaired immediately.

This document should be handed over to the

client on completion of works.

Index

1 Transport and storage of collectors ...........................................................................................................................3

2 Mounting accessories ...............................................................................................................................................3

3 Installation..................................................................................................................................................................5

4 Planning and layout data for collectors ....................................................................................................................12

5 Technical data..........................................................................................................................................................13

6 Safety instructions....................................................................................................................................................13

7 General operation and maintenance instruction ......................................................................................................14

8 Solar fluid .................................................................................................................................................................15

9 Warranties ...............................................................................................................................................................17

10 Installation and maintenance record ......................................................................................................................18

© Wikora GmbH Page 2 Status: 27.04.2015

Errors excepted.

Pos. Nr. Description

1

2

3

4

5

6

7

8

9

Collector Wikosun 2010 / 2510

Profile rails, aluminum

Z-clamp

Collector support bracket

Parallel compression fitting 18mm

Compression -X-fitting 18x18x12“x3/4“FD incl. air screw and sensor pocket

Insulation, on site

Compression plug 18mm

Compression-elbow 18mm x 3/4“FD

Chart 1: Part list

5

1

6

9

8

9 2

4

7

5

1

3

8

7

3

© Wikora GmbH Page 3 Status: 27.04.2015

Errors excepted.

1 Transport and storage of collectors

Collectors should be transported in their packaging horizontally (glass facing upward) or vertically. It must be ensured that

collectors can at any time be safely put down (e.g. tilting danger by wind, endangering of other people). Collectors should never

be put down over the edge! Please take special precaution while transporting the collectors on the roof. If collectors can not be

put down at any time and/or if a risk of slipping exists, auxiliary material like safety ropes should be used.

Store collectors in closed and sun-protected areas either horizontally with the glass facing upward or in an upright position. Do

not stack collectors on their connectors.

2 Mounting accessories

2.1 Fastening set “on roof mounting” – vertical / horizontal installation – roof angles from 25-60°

Various fastening sets (tile, adjustable tile, slate, plain tile, corrugated fibre cement, profiled sheeting, stair bolts, standing seam

clamp) are offered for the vertical/horizontal installation of WIKOSUN 2010 / 2510. Each fastening set consists of two mounting

anchors. The total quantity of anchors needed is defined by the number of collectors to be installed and the rafter spacing.

Fastening set

Content

ST-BFS-Z 2 roof hooks tile , 6 wood screws 8x80, 6 washers

ST-BFS-ZV 2 roof hooks adjustable tile, 6 wood screws 8x80, 6 washers

ST-BFS-B 2 roof hooks plain tile, 6 wood screws 8x80, 6 washers

ST-BFS-S 2 roof hooks slate, 6 wood screws 8x80, 6 washers

ST-BFS-BL 2 clamps for rolled steel joist , 2 screws M8, 2 nuts M8

ST-BFS-ST 2 stair bolts M10, 2 ears, 6 nuts, 2 seals

ST-BFS-T 2 roof hooks profiled sheeting

ST-BFS-W 2 roof hooks corrugated sheet iron roofs

Chart 2: Fastening sets „on roof mounting“ – vertical/horizontal installation

2.2 Fastening set “flat roof mounting – vertical installation – roof angles from 30-60°

A basic kit (for 1-2 collectors) and an extension kit (for 1 collector) are offered for the vertical installation of WIKOSUN 2010 /

2510. The basic kit consists of two carriers comprising angle sections with an adjustable tilt angle (30/45/60°), two back bars

comprising flat sections, and a screw set.

The extension kit consists of a carrier comprising angle sections with an adjustable tilt angle (30/45/60°), a back bar comprising

a flat section and a screw set.

Fastening set

Content

Basic kit for 1-2 collectors

WIKOSUN 2010 / 2510

ST-BFS-1FVG

2 Angle sections aluminum 40 x 40 mm, s = 4 mm, l = 1875 mm

2 Angle sections aluminum 40 x 40 mm, s = 4 mm, l = 2140 mm

4 Angle sections aluminum 35 x 55 mm, s = 8 mm; l = 50 mm

2 Flat sections aluminum l = 500 mm, s = 5 mm

2 Flat sections aluminum l = 1920 mm, s = 5 mm

15 Hex head screws, stainless steel M8 x 20 mm

15 Hex nuts, stainless steel M8

15 Lock washers M8

Extension kit for 1 collector

WIKOSUN 2010 / 2510

ST-BFS-1FVE

1 Angle section aluminum 40 x 40 mm, s = 4 mm, l = 1875 mm

1 Angle section aluminum 40 x 40 mm, s = 4 mm, l = 2140 mm

2 Angle sections aluminum 35 x 55 mm, s = 8 mm; l = 50 mm

1 Flat section aluminum 40x5, l = 500 mm

1 Flat section aluminum 40x5, l = 1920 mm

7 Hex head screws, stainless steel M8 x 20 mm

7 Hex nuts, stainless steel M8

7 Lock washers M8

Chart 3: Fastening sets „flat roof mounting“ – horizontal installation

© Wikora GmbH Page 4 Status: 27.04.2015

Errors excepted.

2.3 Fastening set “flat roof mounting – horizontal installation – roof angles from 30-60°

A basic kit (for 1-2 collectors) and an extension kit (for 1 collector) are offered for the horizontal installation of WIKOSUN 2010 /

2510. The basic kit consists of two carriers comprising angle sections with an adjustable tilt angle (30/45/60°), two back bars

comprising flat sections, and a screw set.

The extension kit consists of a carrier comprising angle sections with an adjustable tilt angle (30/45/60°), a back bar comprising

a flat section and a screw set.

Fastening set

Content

Basic kit for 1 collector

WIKOSUN 2010 / 2510

ST-BFS-1FHG

2 Angle sections aluminum 40 x 40 mm, s = 4 mm, l = 1100 mm

2 Angle sections aluminum 40 x 40 mm, s = 4 mm, l = 1250 mm

4 Angle sections aluminum 35 x 55 mm, s = 8 mm; l = 50 mm

2 Flat sections aluminum 40x5 mm, l = 300 mm, s = 5 mm

2 Flat sections aluminum 40x5 mm, l = 1710 mm, s = 5 mm

15 Hex head screws, stainless steel M8 x 20 mm

15 Hex nuts, stainless steel M8

15 Lock washers M8

Extension kit for 1 collector

WIKOSUN 2010 / 2510

ST-BFS-1FHE

1 Angle section aluminum 40 x 40 mm, s = 4 mm, l = 1100 mm

1 Angle section aluminum 40 x 40 mm, s = 4 mm, l = 1250 mm

2 Angle sections aluminum 35 x 55 mm, s = 8 mm; l = 50 mm

1 Flat section aluminum 40x5 mm, l = 300 mm, s = 5 mm

1 Flat section aluminum 40x5 mm, l = 1710 mm, s = 5 mm

7 Hex head screws, stainless steel M8 x 20 mm

7 Hex nuts, stainless steel M8

7 Lock washers M8

Chart 4: Fastening sets „flat roof mounting“ – horizontal installation

2.4 Profile rail sets / Connectors

Profile rail set

Content

ST-PSS-1V 2 profile rails 35x35x 1200mm, 4 Z-clamps, 4 screws M8x20, 4 screws M8x35, 8 nuts M8, 8 washers,

2 K-profiles

ST-PSS-2V 2 profile rails 35x35x 2400mm, 8 Z-clamps, 8 screws M8x20, 6 screws M8x35, 14 nuts M8, 14 washers, 4 K-

profiles

ST-PSS-3V 2 profile rails 35x35x 3600mm, 12 Z-clamps, 12screws M8x20, 8 screws M8x35, 20 nuts M8, 20 washers, 6 K-

profiles

ST-PSS-1H 2 profile rails 35x35x 1800mm, 4 Z-clamps, 4 screws M8x20, 4 screws M8x35, 8 nuts M8, 8 washers,

2 K-profiles

ST-PSS-1.1H 2 profile rails 35x35x 2400mm, 4 Z-clamps, 4 screws M8x20, 4 screws M8x35, 8 nuts M8, 8 washers, 2 K-

profiles

ST-PSS-V 2 Alu angle180mm, 8 screws M8x20, 8 nuts M8, 8 lock washers

Chart 5: Profile rails - horizontal / vertical installation

2.5 Connection accessories

Connection

accessories

Content

ST-AZV-1FK 1 cross piece 18mmxGi1/2“xGi1/2“xGa ¾“, 1 air vent ½“, 1 sensor pocket ½“, 2 end caps 18mm, 2 copper

gaskets ½“, angle 90°18mm x Ga3/4“

ST-VZV-1FK 2 DG-fittings 18mmx18mm

ST-AZH-1FK 1 cross piece 18mm x Gi1/2“ x Gi ½“ x 18mm, 1 air vent ½“ 1 sensor pocket ½“, 2 end caps 18mm, 2 copper

gaskets ½“, 1 angle 90°18mm x 18mm, 2 connecting nipples 18mm x Ga3/4“

ST-VZH-1FK 2 T-piece18mm x 18mm x 18mm, 2 end caps 18mm

Chart 6: Connection accessories - horizontal / vertical installation

© Wikora GmbH Page 5 Status: 27.04.2015

Errors excepted.

3 Installation

3.1 In general

Prior to installation:

•Check the content of the delivery with the delivery note!

•Read the installation instructions carefully and pay attention to the different steps!

•Respect the safety instructions!

This mounting material is structurally approved for assembly with collectors 2010 / 2510 up to a maximum building

height of eight metres. If the collectors are installed on roofs with high wind or snow loads (> 1.0 kN/m²), the load must

be distributed across additional mounts (see chart 2).

3.1.1 Snow/wind load

For structural analysis purposes, we recommend calculations according to DIN 1055. Calculations of the pressure

coefficients (wind) and shape coefficients (snow) are carried out with reference to DIN 1055 -100, DIN 1055-4 and DIN

1055-5. Determine the values of local snow loads according to country-specific data.

Determine the values of local wind loads according to country-specific data. The loads that exist locally (in kN/m²)

must be determined according to the nationally applicable norms. In the case of intermediate values, no interpolation

should be done; instead, the next higher value should be selected.

The values for weighting down the flat roof mounting systems to cope with the wind load can be found on page 8

(chart 8).

Necessary tools Application

Socket key or ratch with extension SW 13

Combination spanner SW 13

Open-ended spanner SW 21

Open-ended spanner SW 27

Pipe tongs

Drill d=9mm

Angle grinder

Hacksaw

Installation of carriers, profile rails and Z-clamps

Sensor pocket

Parallel compression fitting

Variable adjustment of tilt angle

Tile adjustment

Shortening of vertical angle profiles at angle of 30/45°

Chart 7: Tool list

© Wikora GmbH Page 6 Status: 27.04.2015

Errors excepted.

3.2 On roof mounting

3.2.1 Positioining of collectors

Wind loads on roofs can create suction forces on the solar

collectors. In order to minimize suction forces, the distance

between the outer edge of the roof and the collector should be

minimum 70 cm (about 3 tiles). The distance from the roof ridge

should be approx. 2 tile rows (see fig. 1).

. Fig. 1: Positioning of collectors

3.2.2 Fixation of brackets

Measure the area of the collector field on the roof and define the position of the brackets (see

fig. 2 and 3). Brackets should be installed dimensionally mediated according to the number of collectors.

The distances between the upper and lower profile rail are as follows (see fig. 4):

On roof mounting

vertical 1500 – 1600 mm (WIKOSUN 2010) 1800 - 1900 mm (WIKOSUN 2510)

horizontal 800 - 900 mm

Flat roof mounting

vertical 1705 mm (determined by drill holes in carriers)

horizontal 8155 mm (determined by drill holes in carriers)

Installation takes place in such a manner that the laces of the fastener penetrate the roofing at the deepest point of each tile.

Fig. 2: Measuring of roof area

Fig. 3: Roof opening

Fig. 4: Adjustment of profile rails

Always ensure that three rafter bolts 8 x 80 are screwed into the rafter for each bracket. The rafter bracket bolts must be

screwed at least 1 cm in from the edge of rafter timbers.

Fig. 5: Fixation of brackets

© Wikora GmbH Page 7 Status: 27.04.2015

Errors excepted.

If the rafter width is greater than 80mm, brackets can be fixed without any problems. Smaller rafters should be doubled or

trebled in width at the point where brackets are to be fixed to them (see fig. 6).

If a foil under the roof tiles exist and is harmed during installation, the opening should be sealed accordingly. Remove the

drainage area of the tiles where brackets are located and close the roofing.

Fig. 6: False edge

© Wikora GmbH Page 8 Status: 27.04.2015

Errors excepted.

3.3 Flat roof mounting

3.3.1 Mounting possibilities

Wind loads on roofs can create suction forces on the solar collectors. In order to minimize suction forces, the mounting frame

must be installed as follows.

The subsurface must be sufficiently sustainable and appropriate for the weights to be installed. Hence, it is important to verify

in advance the static appropriateness as well as the allowed distributed load.

If the mounting frame will not be connected with the subsurface (structure, roof sub-construction), a loading of at least 200 kg

per collector is required (see chart 8). Additionally, the mounting frame can be connected with wire-ropes at fixed hold points.

Support elements and fasteners must be provided by the installer. Moreover, in order to avoid wind noise to a large extent, the

mounting frame must be installed at least 1 m from the roof edge. In areas with high wind speed or big construction heights, the

loading must be unconditionally calculated.

Height of construction Horizontal installation Vertical installation

0 – 5m 200 kg 300 kg

5 – 10 m 250 kg 350 kg

10 – 20 m 300 kg 400 kg

> 20 m Calculation necessary

Chart 8 : Loading per collector

3.3.1.1 Installation of the mounting frame on mass elements e.g. concrete slab

The frame base can be installed e.g. on large concrete slabs (e.g. ST-

GWE-20) (see fig. 7). Please note that the concrete slabs (mass

elements) must be degenerated by an additional separating layer

(bitumen felt, e.g. ST-BSM-40) from the roof surface to avoid damages

or leakage.

Fig. 7 : Installation on mass elements

3.3.1.2 Installation of the mounting frame on large surface e.g. galvanized trapezoidal sheet

The charge can also be installed on a weather-resistant sheet (e.g.

galvanized trapezoidal sheet) which is weighed with pebble or substrate

(see fig. 2). Please note that the frame base must be connected with

the surface with min. power socket wrenches M8 and large discs.

Fig. 8 : Installation on large surfaces

3.3.1.3 Connection of the mounting frame with the roof sub-construction

If the mounting frame is directly connected with the roof sub-construction (not recommended), perforations must be

professionally sealed and established permanently leak proof against humidity. Damages that are caused due to storms or

unprofessional sealing are not part of the warranty.

© Wikora GmbH Page 9 Status: 27.04.2015

Errors excepted.

3.3.2 Alignment and installation

3.3.2.1 In general

The collectors should be aligned southward and show an ideal angle

according to latitude and application. The mounting frame can be

installed with different angles (30/45/60°). In addition, a variable angle

adjustment between 30 and 60°can be carried out on site.

According the angle, the measures A and B (distance of mounting

points) change. The lengths A and B for different collectors and angles

are indicated in the chart below:

Distances – vertical installation (mm)

Angle A B C D E F G H I J

30° 1840 1070 810 540

385 50 50

1825

o

r

1100

1000

or

2000

200045° 1500 1515 1070 655

60° 1065 1850 1515 920

Distances – horizontal installation (mm)

30° 1075 625 475 325

385 50 50 815 1600 160045° 875 880 625 385

60° 620 1085 880 550

Fig. 9: Lateral view with hole center distances

3.3.2.2 Mounting procedure

Define the angles of the collectors and install the mounting frame as depicted in fig 9, 10 and 11.

If the system is to be installed with another angle as foreseen, additional holes can be added. The distances of the holes must

then be calculated and measured. For roof angles smaller than 60°, the vertical angle section must be cut 25mm above the

hole.

Install the base of the frame, the cross bars and the back bars and connect the angle section according to fig. 10a. Bases’

screws should be fitted with the head on the side of the angle as shown in fig. 10b.

Define the leading edge of the mounting frame and mark the holes accordingly.

Distance of the carriers of the first mounting frame - vertical installation (I): 1000/2000mm

Distance of additional carriers - vertical installation (J): 2000 mm

Distance of the carriers of the first mounting frame - horizontal installation (I): 1600 mm

Distance of additional carriers – horizontal installation (F): 1600 mm

The holes of the vertical angle sections should be marked with the distance A in a right angle (use chalk line and angle). It is

also possible to mark the holes after the assembling of the mounting frame.

Put the mounting frame on the fixing points and tighten all screws.

The base must be connected and fixed with the surface.

The distance of the collectors from the surface should be about 20 cm to guarantee that collectors remain free from snow

during winter and that no dirt from the ground reaches the glass during strong rain.

Fig. 10 : Base mounting

FF F

GGG

H

E

HH

E E

H

JI

Fig 11 : Front view first mounting frame + extension

© Wikora GmbH Page 10 Status: 27.04.2015

Errors excepted.

3.4 Installation of profile rails and kiln furniture

After the installation of all roof hooks or carriers, the pre-mounted profile rails are aligned in the center and fixed to the long

hole of the roof hooks or, in the case of flat roof mounting, at positions E/F of the carriers with the pre-installed M8x35 bolts,

washers and nuts . Measure the distances between the mounts when installing the profile rails to ensure all carrying elements

are vertically aligned. Subsequently, roughly align the pre-mounted Z-clamps on the profile rails and hook the collector support

brackets into the lower profile at a distance of about 20 cm from the edge of the collector. These serve as provisional mounts

and will not be removed after securing.

3.5 Installation and connection of collectors

Slide the collectors down onto the collector support brackets and lower the collectors onto the top rail.

Position the collectors and fix them carefully. The collectors are connected with each other by using the corresponding parallel

compression fittings. Hand tighten the bolts and protect the connecting pipes against torsion (do not use force).

Please note that the collector arrays are always connected at diagonal corners and the throughflow is diagonal. A one-sided

connection is not permitted.

After the hydraulic pressure test, the connections should be insulated.

The collectors must not be covered in order to guarantee good ventilation.

Fig. 12: Connection of collectors, vertical Fig. 13: Connection of collectors, horizontal

3.6 Connection of additional collectors

For the installation of an additional collector, an additional connection kit is required (see mounting accessories). The profile

rails are connected with the connection accessories ST-PSS-V. Maximum 6 collectors can be installed in series.

After the hydraulic pressure test, the connections should be insulated.

The collectors must not be covered in order to guarantee good ventilation.

Bolt M8x20

Nut + washer

M8

Z

-

clamp

Z-clamp

Profile rail mounted on roof

hooks or carrier

Collec

tor

© Wikora GmbH Page 11 Status: 27.04.2015

Errors excepted.

3.7 Installation of collector temperature sensor

The collector temperature sensor is to be installed at the flow of the system (hot water side). Put the sensor into the sensor

pocket as far as it will go. Apply a heat-conductive paste onto the sensor to improve the heat transfer. Screw carefully the cable

sheet on the sensor pocket.

The 1 m cable is laid with the pipe work through the roofing. The cable can be extended in the interior

(2 x 0,75²). For the connection of the temperature sensor cable with the controller the use of an over voltage protection

(protection against over voltage damages) is recommended.

If there is a lightning protection system, the collector system is to be integrated professionally. If there is no lightning protection

system, the solar flow and return are generally to be connected to the equipotential bonding. In every case, the regulations of

the local energy provider / network operator should be observed here. Electrical and lightning protection work may only be

carried out by authorized professionals.

3.8 Installation of pipe work

Install the pipe work:

on shortest way to minimize losses.

with a complete high temperature insulation (100% according to EnEv).

rising to the collector to prevent air cushions.

3.9 Hydraulic pressure test

After a successful installation, rinse the entire collector circulation with water!

Before commissioning, the collector circulation must be checked with a water pressure of 6 bar!

If the solar heating system is not commissioned immediately after installation, the collector area must be covered!

Before filling the system with heat transfer fluid, the system must be completely purged!

Open the lower plug at the collector field to purge the system.

Subsequently, the system is to be filled with solar fluid. The liquid capacity amounts to 1,15 Liter for Wikosun 2010 and 2,2

Liter for Wikosun 2510.

Important:

Please note that only a solar concentrate released by Wikora may be refilled. Solar concentrate must be prepared according to

manufacturer’s specifications with clean, ph-neutral and lime-free water. Please use an antifreeze controller to ensure the

antifreeze capacity. If another solar concentrate is applied, the warranty expires automatically. Moreover, damages that are

due to an insufficient antifreeze protection are not part of the warranty.

3.10 Regulation of flow rate (flow regulation)

The set-up of the flow rate is important for an efficient functioning of the system. The lower the flow rate chosen, the higher

the temperature difference between collector flow and return.

When setting the flow rate, it is absolutely essential to refer to the instruction manuals of the pump groups / temperature

difference controler used (scale).

Fig. 14: Scale

© Wikora GmbH Page 12 Status: 27.04.2015

Errors excepted.

4 Planning and layout data for collectors

Recommendation:

System pressure

Primary pressure of expansion vessel

Flow rate

Switch-on temperature difference of controller

Switch-off temperature difference of controller

3,0 bar

2,5 bar

30 – 40l /m²/h

7 to 15 K *

3 to 8 K * (*internal to the plant)

Please note that for the layout of the collector circuit, the solar tube circuit and the heat exchanger circuit, the corresponding

pressure losses and the total pressure loss in combination with the desired flow rate must be considered.

Furthermore, please note that the calculation of the piping cross-sections must be carried out under the aspect of the

necessary flow velocity for solar installations from min. 0.4 m/s up to max. 1,5 m/s with the required flow rate liter/h.

Moreover, it must be considered that the hydraulic faulty wiring results in a system specific and demand specific flow rate which

involves a loss of pressure. This again has an influence on the layout of piping cross-sections, solar medium capacities, pump

pressures, flow-meter set-ups and flow-meter configurations as well as on their number.

The values indicated in chart 9 apply only for pipe works up to an overall length of 30 m and heat exchangers with a capacity of

16 l.

Number of collectors 2 3 4 5 6 7 8 9 10

External diameter of the CU-connection pipe in mm

Flow rate in l/min*

Flow rate in l/h*

Expansion vessel in l

15

3

180

18

15

4,5

270

18

18

6

360

25

18

7,5

450

25

18

9

540

40

22

10,5

630

40

22

12

720

50

22

13,5

810

50

28

15

900

80

*Valid for parallel collector connection . In the case of series connection of the same collector arrays, the flow rate is halved.

Chart 9: Reference values for pipe work size, flow rates and diaphragm type expansion vessels.

Each solar system needs an adequate and competent planning and execution. Please note that only a specialized

company is responsible for the layout of piping cross-sections, the layout of diaphragm type expansion vessel, the

determination of the solar pump group as well as the necessary flow-meter. Our data do not relieve of a special planning.

4.1 Hydraulic faulty wiring possibilities

Our warranty covers the following configurations. Up to 6 collectors can be connected in parallel (see fig. 15). In case of an

installation in two lines, up to 3 collectors can be connected in series (see fig. 16). Please always ensure that all collectors are

connected uniformly and with a diagonal throughflow. A one-sided connection is not permitted. The connections between the

collectors must be realized with copper tubes of 18mm and an appropriate insulation. The collector fittings must be prepared

with the corresponding compression.

Crimp connections in the pipe work system are allowed. Seals must be approved for use in combination with solar systems and

temperatures up to 200°C. In case of a multiple-line installation, the return (cold water connection) should be located at the

collector line on the bottom.

Fig. 15: Installation in one line (4-5l / min.)

Fig. 18: Horizontal series installation according to Tichelmann

(4-5l / min.)

Fig. 16: Installation in two lines (4-5l / min.)

Fig. 17: Vertical

installation (4-5l / min.)

© Wikora GmbH Page 13 Status: 27.04.2015

Errors excepted.

5 Technical data

Description WIKOSUN 2010 WIKOSUN 2510

System Flat plate collector

Flat plate collector

Collector gross surface 1,98 m

2

2,47m

2

Absorber surface 1,87 m

2

2,32 m

2

Aperture surface 1,87 m

2

2,32m

2

Frame Aluminum extruded profile

Aluminum extruded profile

Dimensions:

Length x width x height 1740 x 1140 x 75 mm 2170 x 1140 x 75 mm

Weight 32 kg 40 kg

Cover 3,2 mm safety glass, super transparent, hailstone safe 3,2 mm safety glass, super transparent, hailstone safe

Connections Cu-tube d=18 mm d=18 mm

Thermal insulation: 40 mm of mineral wool

40 mm of mineral wool

Absorber:

Material Aluminium plate on copper Aluminium plate on copper

Absorber coating TINOX ENERGY / Alanod Mirotherm TINOX ENERGY / Alanod Mirotherm

Pressure loss:

50\,l/h 49 Pa/collector 54 Pa/ collector

100\,l/h 120 Pa/ collector 133 Pa/ collector

150\,l/h 214 Pa/ collector 239 Pa/ collector

Efficiency η= 74,4 η= 76,1

Peak power 1380 Watt per collector 1750 Watt per collector

Capacity 1,15 Liter 1,33 Liter

Max. working pressure 10 bar 10 bar

Stagnation temperature 179 °C 197°C

Installation on-roof, flat-roof, in-roof on-roof, flat-roof, in-roof

Return:

Collectors can be returned to Wikora after use. All collector material will be recycled accordingly by Wikora.

6 Safety instructions

The installation of collector and solar components must comply with the local regulations and conditions. Technical standards

and rules have to be respected.

© Wikora GmbH Page 14 Status: 27.04.2015

Errors excepted.

7 General operation and maintenance instruction

Present operation and maintenance instruction and the compliance with it in combination with the installation and maintenance

record is part of the guarantee and warranty!

Operation

Your Wikora solar heating system is preset according to the present installation and maintenance record. In general,

there is no need of changing the preset parameters.

Please do not change the preset parameters by yourself. You will lose any warranty and guarantee claim.

If you do not conform to the preset parameters, please let them change and document by a specialist.

The various system parameters can be accessed according to enclosed instruction manual of the controller.

It is recommended to vent the solar heating system approx. 4 weeks after the initial operation. This should be

undertaken by a specialist. If you wish to vent the system by yourself, you can do it one-time at the central vent of the

solar pump group.

Venting procedure

Please switch off your solar heating system in the evening.

Open the air valve at the central vent by using a radiator vent key. Once liquid pours out, close this air valve. The

procedure is terminated.

Switch on again your solar heating system.

Please never vent at sunshine or running pump!

Please do not undertake an additional venting process. If the system’s working pressure drops later on or if the

system does not give any heat, please call a specialist.

Maintenance of solar heating system

Your Wikora solar heating system is a closed heating system. It corresponds to the safety regulations of DIN 4751,

DIN 702 and DIN 721.

Such systems have to be built and maintained exclusively by qualified and specialized companies.

Please do not refill water in case of pressure loss but call a specialist for assistance.

Only a solar concentrate released by Wikora may be refilled.

The valid system working pressure is shown in the installation and maintenance record and corresponds to 3.0 bar, in

general.

Please do never remove the drain bottle under the exhaust line of the safety valve which is to collect the blast solar

liquid in case of over pressure.

The solar heating system and the condition of the solar concentrate are to be checked and documented annually by a

specialist. Otherwise, any guarantee and warranty claim expires.

7.1 Evidence of maintenance

Date Name / Company Executed activity Kg refilled sole Color medium

1

□uncolored

□brown

□black

□cloudy

2

□uncolored

□brown

□black

□cloudy

3

□uncolored

□brown

□black

□cloudy

4

□uncolored

□brown

□black

□cloudy

5

□uncolored

□brown

□black

□cloudy

Chart 10: Evidence of maintenance

© Wikora GmbH Page 15 Status: 27.04.2015

Errors excepted.

8 Solar fluid

8.1 Product information Solarliquid ready for use (WIK-PE20)

Environmentally friendly, ready-to-use long-term antifreeze with corrosion inhibitors especially for flat plate and

vacuum tube collectors with a high thermal load (up to 260 °C).

Product data:

Appearance: clear, amber liquid

Base: superior glycol

Flashpoint (°C): > 100 (ASTM D 51758)

Boiling point (°C): > 102 (ASTM D 1120)

Density (20 °C): 1.02 – 1.04 g/cm³ (DIN 51757)

Antifreeze (crystallization point): approx. -23 °C

Antifreeze (solidification point): approx. -29 °C

pH value (20 °C): 7.5 – 8.5 (ASTM D 1287)

Viscosity (20 °C): approx. 15.0 mm²/s

Product properties:

SOLARLIQUID HT ready for use is an odorless liquid that is used as antifreeze or heat transfer fluid for thermal solar

installations (flat plate and vacuum tube collectors) with a high thermal load. The special corrosion inhibitors protect the metal

and plastic materials commonly used in construction, including aluminium, against corrosion and deposits. The sealing

materials commonly used in heating installations are not affeced by Solarliquid HT ready for use.

SOLARLIQUID HT ready for use

cannot be mixed with any other type of antifreeze

is inhibited nitrite-, amine- and phosphate-free

is biodegradable

According to the German Ordinance on Hazardous Substances, no specific labeling is required for Solarliquid L concentrate

ready for use and HT ready for use (see safety data sheet).

General information:

The systems must conform to DIN standard 4757, part 1, and be implemented as a closed system, since there must be no

atmospheric oxygen in the system. It must be ensured that the circulating pump is suitable for operation with antifreeze agents.

Before being filled, the system should be flushed with water and the tightness of all connections checked through pressure

testing. The system must be free of impurities and free of other liquids. There must be no deposits on the metal surfaces. After

pressure testing, the system must immediately be filled with Solarliquid HT ready for use. Do not allow any air to enter!

Galvanized system components should be avoided since zinc is not resistant to glycols. In the case of leakage, only top up with

the same product, never utilize different solar liquids in the same system. In our experience, Solarliquid HT ready for use can

be stored or used for several years. Nonetheless, the concentration (frost resistance) should be checked annually. In the case

of a loss of liquid, never top up with water.

Use only Solarliquid HT ready for use for topping up!

Recommendation for use:

The optimum temperature for use is between -23 °C and 230 °C. For prolonged temperatures of more than 230 °C we

recommend installing adequately large expansion tanks so that the heat transfer fluid can flow out of the collectors.

Method of testing corrosion properties:

We recommend that the solar fluid with which the system is filled be checked regularly (roughly annually). With the pH value

you can test the corrosion properties of our solar fluid. The pH value should be > 7.5. This is measured using pH test strips. If

the value is lower than this, the solar fluid should be replaced.

Method of testing frost protection:

Krüss device Refractometer

Frost

protection

Brix RI MEG scale MPG scale

-8 °C

22.3

1.3676

-17 °C

-13 °C

-15 °C

29.6

1.3807

-29 °C

-22 °C

-23 °C

35.7

1.3915

-46 °C

-35 °C

© Wikora GmbH Page 16 Status: 27.04.2015

Errors excepted.

8.2 Safety Data Sheet

According to 1907/2006/EG, article 31– extract

Printing date:: 27.02.2013 revised on: 27.02.2013

Product information:

Commercial name:

Article code:

Application:

Decomposition products::

Supplier:

Solarliquid HT gebr.

1004081523000

Antifreeze / Solar liquid of solar heating systems

Carbon monoxide and carbon dioxide

Staub & Co. Chemiehandelsgesellschaft mbH

Ostendstraße 124

90428 Nürnberg

Tel.: 0911/5482- 0

Emergency: Giftnotruf Universität Mainz - Tel.: 06131/19240

General safety and hygienic measures

The usual precautionary measures while handling chemicals are to be considered

•Soiled and soaked clothes should be taken off immediately.

•Wash your hands before breaks and after end of work.

•Don’t eat, drink and smoke during work.

•Don’t inhale gases, vapors and ensure sufficient ventilation.

•Wary perfection equipment; unprotected persons should be kept away.

•Eye protection: wear safety glasses during the filling procedure.

•Respiratory protection: wear respiratory protection during aerosol or fog formation.

•Hand protection: Use protection gloves of butyl rubber, nitril rubber/nitrillatex

The product doesn’t require any specific labeling according to the last version of the ,,Allgemeinen Einstufungsrichtlinie für

Zubereitungen der EG''.

Keep the liquid out of the reachability of canalizations or waters. It the product enters the soil, waters or canalization, please

inform the local authority in charge.

Cleaning: clean with liquid binding material (sand, kieselguhr, acid binder or universal binder). Recycle contaminated material

separately.

Keep the concentrate in a cool and dry environment. Protect against humidity and water. Provide sufficient ventilation during

work.

First aid

If the product gets in contact with the eye, a slight irritation can occur.

•After inhalation: take fresh air and consult a doctor in case of medical condition.

•After skin contact: wash immediately with water and soap.

•After eye contact: wash the open eye for several minutes. Consult a doctor in case of medical condition.

•After swallowing: rinse the mouth and drink plenty of water. Consult a doctor in case of medical condition.

•After contact with cloths: remove soiled clothes immediately.

Fire fighting

•Suitable fire extinguishing agents: CO2, solid extinguishing agent or water. Fight larger fire with water jet or alcohol-

steady foam. Cool tanks at risk with water jet. Collect contaminated fire water separately. It must not reach

canalization.

•Combustion products: carbon monoxide (CO); carbon dioxide (CO2).

•Special protection equipment: carry protective respirator that is not depending on the ambient air.

Recycling

Recycling must be carried out according to local regulations. The waste code number (according to AVV) is to be determined

separately.

The product is only designated for commercial processing / use. The data is based on our today’s knowledge but does not

represent any confirmation of product properties and does not constitute a legal position.

All data according to manufacturer data of Fa. Staub & CO Chemiehandelsgesellschaft mbH

© Wikora GmbH Page 17 Status: 27.04.2015

Errors excepted.

9 Warranties

Warranty conditions for Wikora flat plate collectors. All deliveries and services are carried out according to

our general terms and conditions.

1. The warranty period for the collector function amounts to 10 years. Within that period, all parts proven to be useless or

considerably reduced in their usability due to production or material defects are repaired or replaced ex works. At

expiration of the legal warranty period, we have the choice between rectification or replacement.

2. The warranty begins with the delivery of the collectors to the end user and under condition that the system has been

installed and setup by a specialised company according to our installation and operating instructions as well as the

locally valid norms and regulations. Further, the warranty is dependent on a carefully completed installation and

maintenance record which must be filled out by the installer and kept by the system owner.

3. The guaranteeing implies that

the collectors are transported, installed, operated and maintained according to our installation and operating

instructions

the collector system is exclusively operated with our solar liquid.

4. The guaranteeing does not refer to dammages due to

wear and tear, excessive wear, inappropriate operation or inappropriate use,

use of a unsuitable solar fluid or results of corrosion provoced by a solar fluid,

chemical or electro-chemical influences,

incorrect system layout.

5. Moreover, the warranty does not apply for

•damages as a result of an inappropriate storage of the collectors prior to installation and

•damages that are ascribed to force majeure,

•The warranty regarding the safety glass refers to its condition, and here only to manufacturing and material defects.

The cullet security is examined in the context of the inspection requirements for collectors and ensured only

according to these requirements.

6. The warranty expires

if arising and obvious defects are not notified in writing within 10 days after receipt or hidden defects immediately

after emerging. In case of hidden defects it is only valid for the warranty exceeding the legal warranty period,

if the collectors are changed or maintained by non-spezialised persons or companies or undertaken without our prior

agreement,

if the possibility to peer the entire system is not granted or if the collectors are removed without our agreement,

if original Wikora components are exchanged by other components or if inappropriate installation material and

system components as well as nonauthorized solar fluid are used,

if the annual inspection is not realized within the time limit. The proper execution is to be documented by the

specialized company in charge.

7. Transport damages are to be notified immediately, stipulated on the delivery note and signed by the sub-contractor.

§447b BGB remains untouched.

8. After the expiration of the legal warranty period, the warrantee must provide the necessary aide in case of reparation

work and is obliged to assume the necessary services like transport, installation etc. In the event of warranty, we

recompense

for on-roof installation max. 200,00 € + VAT for the first collector and max 80,00 € + VAT for each additional

collector, incl. all consumables.

for in-roof installation max 300.00 € + VAT fort he first collector and max. 90.00 € + VAT for each additional collector,

incl. all consumables.

9. This warranty does not justify claims exceeding the legal liability for physical or personal injuries that have been caused

by the defects of the purchased object. Redhibitory actions and abatements exceeding legal regulations are not justified

either.

10. Other legal claims for warranty and damages in respect of BGB and ProdHaftG remain untouched by this warranty.

11. The exchange or rectification of the collectors or other parts of the solar system must be carried out by the installer and

only after having consulted Wikora. Otherwise an entitlement to compensation does not exists.

12. Notifications of claim are to be announced in writing to WIKORA GmbH and by presenting the installation and

maintenance record as well as the respective proofs immediately after the damage is occurred.

13. Solar accessories are subject to the legal warranty.

*)

flat rate only valid for Germany

© Wikora GmbH Page 18 Status: 27.04.2015

Errors excepted.

10 Installation and maintenance record

Please complete carefully.

The installation and maintenance record is part of the warranty and will be requested in case of complaints with the corresponding invoice.

□Installation □Maintenance

Contact Data

Name

Company

Street No

ZIP / Town

Phone

Mobile

E-mail

Date

Installer

Brand

(designation)

Type

(serial no.)

Material

Yes No Anode type

Vol. l m

2

□□

Vol. l m

2

□□

I II III

Vol. l

Max.

temperature

Difference in

temperature

Hystere =

Delta t off

°C K K

°C K K

°C K K

°C K K

°C

°C Target : l/min Actual: l/min

System working pressure at

°C bar Target : bar Actual : bar

Visual control

Brand / type

Actual value □rinsed

Filling capacity

Liter ph-value □filtered

Mixing ratio

% antifreeze upto □purged

yes / no

yes / no

yes / no

□with AIR-Stop in the solar circuit

□wiht quick vent valve at collectors

Primary pressure exp. vessel

°C

Type

Cooling function * from

□colour unchanged □brown □black □cloudy

Flow rate

Ø , m

System - settings

(Controller setting = *)

Consumer 1* = e.g. DHW

Consumer 2* = e.g. buffer tank 1

System

Minimum value

7

-25°C

Insulation

Thickness mm

Solar liquid

Consumer 3* = e.g. buffer tank 2

Consumer 4* = e.g. swimming pool

Max. collector temperature*

Backup heat target temperature*

Material overview

Characteristics

(dimensions)

Collector

Pipeline (single)

Tank 2

Controller

DHW system

Heat exchanger

Expansion vessel

Installer

First installation Last maintenance

Solar pump

Level

Final customer

Tank 1

For stainless steel tank(s):

Additional corrosion protection needed?

(please consider indications of the local

water supplier)

In case of quick vent valve, please add drawing.

How is the solar ventilation system designed?

Space heating

DHW-mixing valve

Number of collectors

S / SE / SW / E / W ca. Grad

Mounting type

OR / IR / FR / horizontal / vertical

single row / double row / parallel / series

Hydr. connection

Orientation/Pitch

© Wikora GmbH Page 19 Status: 27.04.2015

Errors excepted.

□ok □ok

□ok □ok

□ok □ok

□ok □ok

□ok □ok

Meter reading

Pump 1 h Pump 2 kWh

□yes

□yes

□annually

Remark : Please add proof of invoice.

Inspection interval

□no

□no

General checklist

System is grounded

Collector fastening is stable

User has been instructed

Maintenance contract

Operation of pumps checked

Temperature sensores indicate realistic values

Collector interior is not fogged

Collector is clean

Date, signature and stamp of solar company Datum, signature of customer

Return valves

DHW-mixing valve

Solar liquid for re-filling is available

Anode(s) checked

h Heat quantity meter

Drawing of collector array

□every 2 years, no later than

This manual suits for next models

1

Table of contents