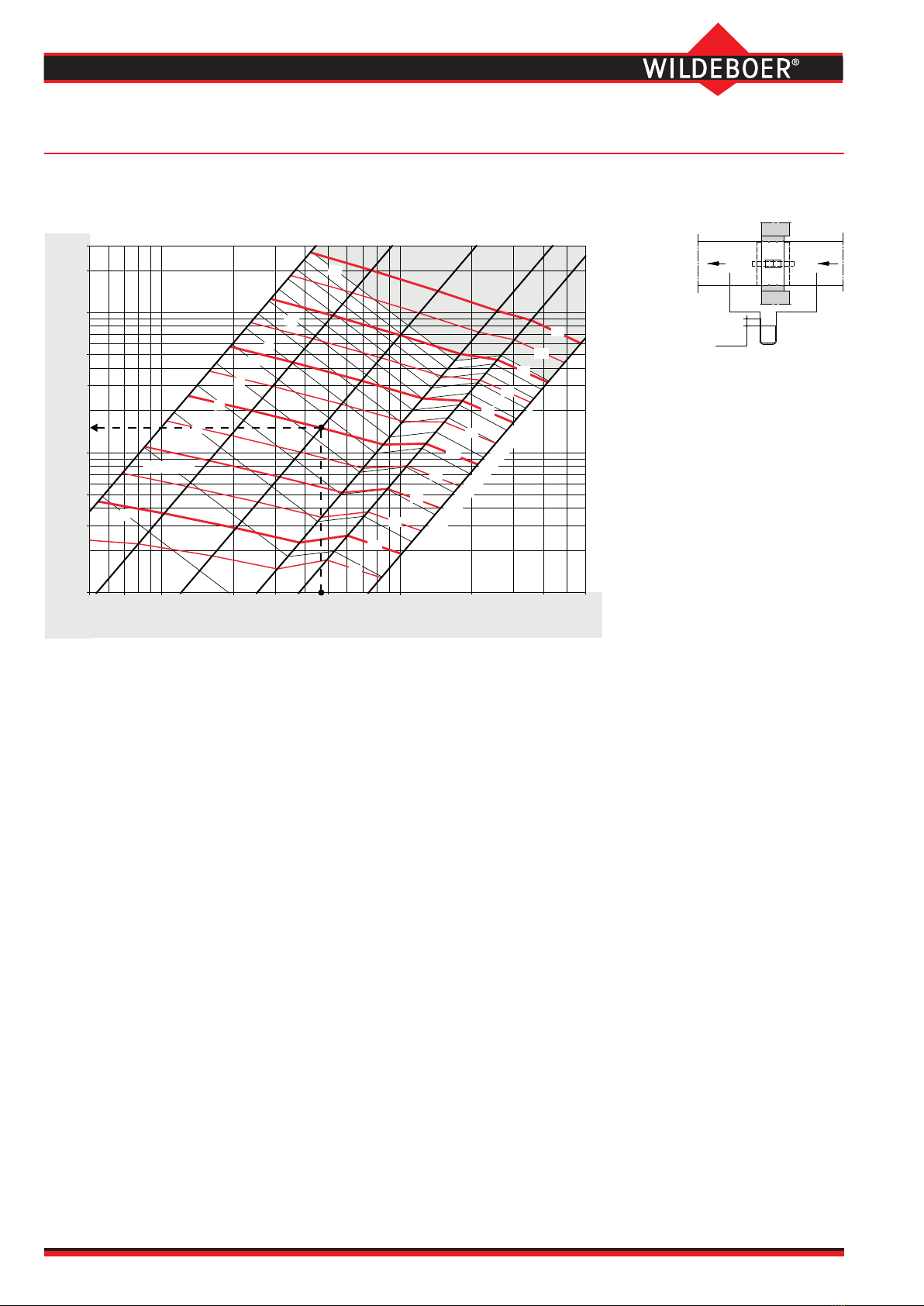

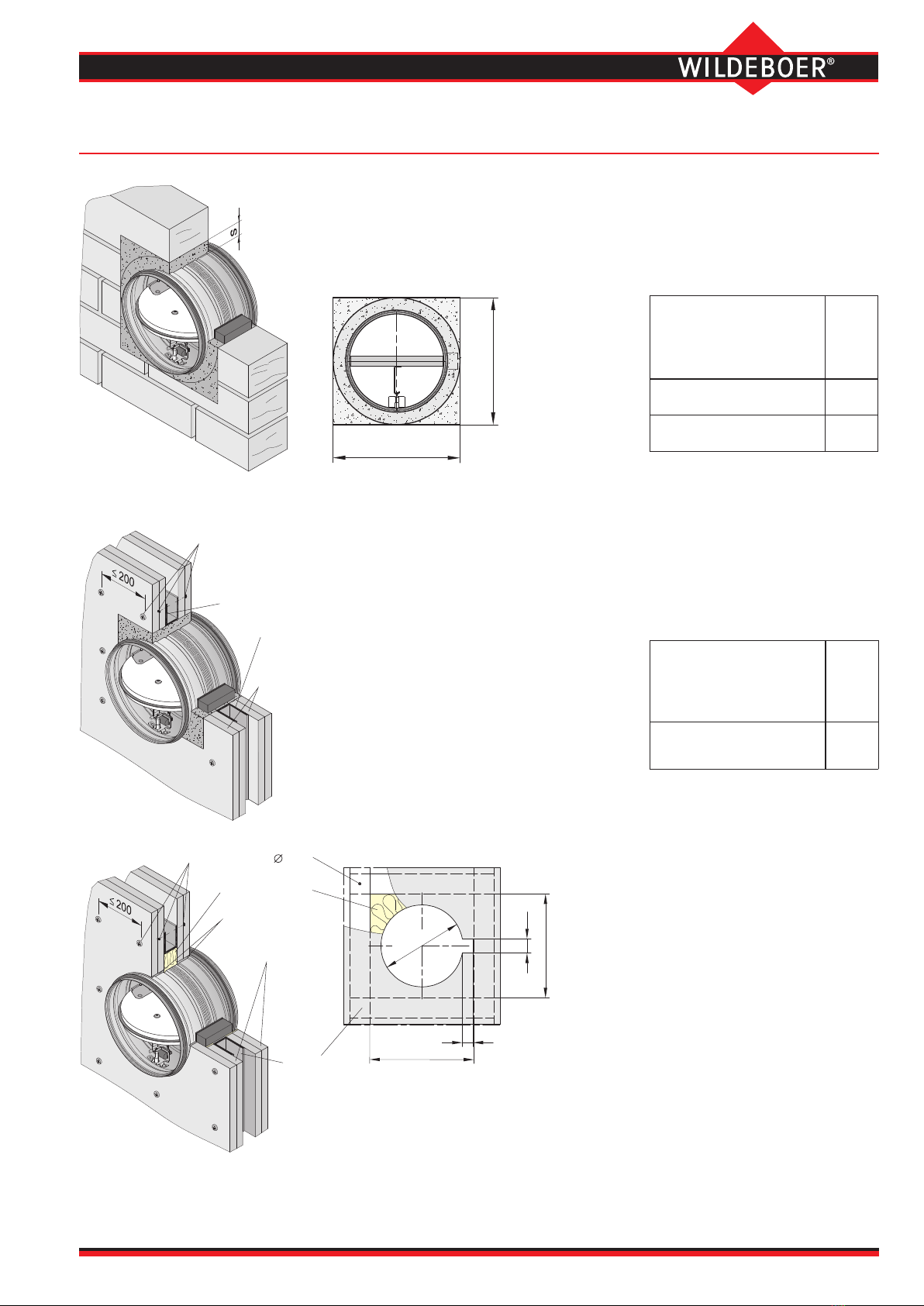

25 25

150

100

d

2

8

7

3

10

1

L1

L2

8

User Manual 5.12 (2019-09) 3

Subject to change Series FR92K

FR90 re dampers in short lengths

Description

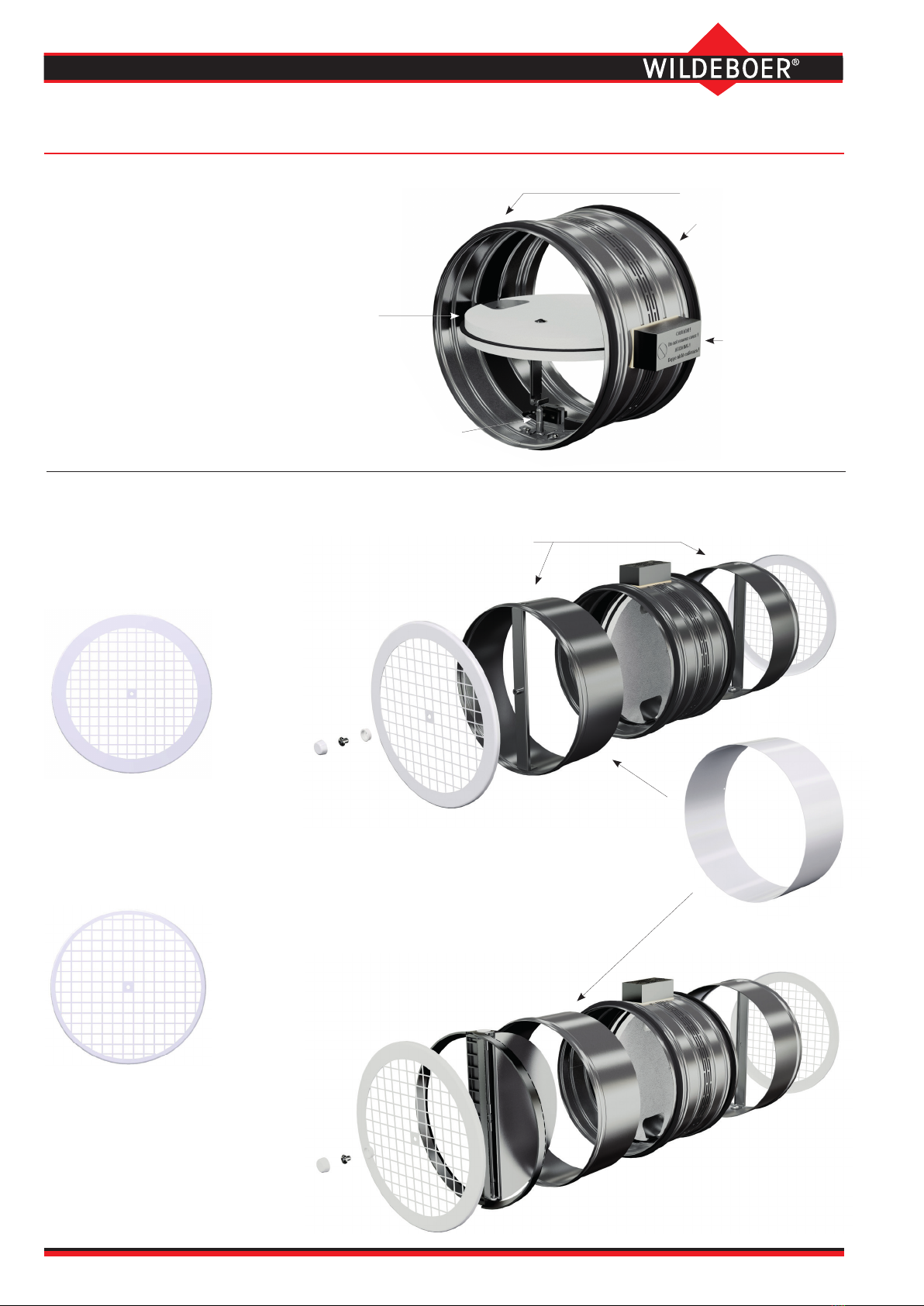

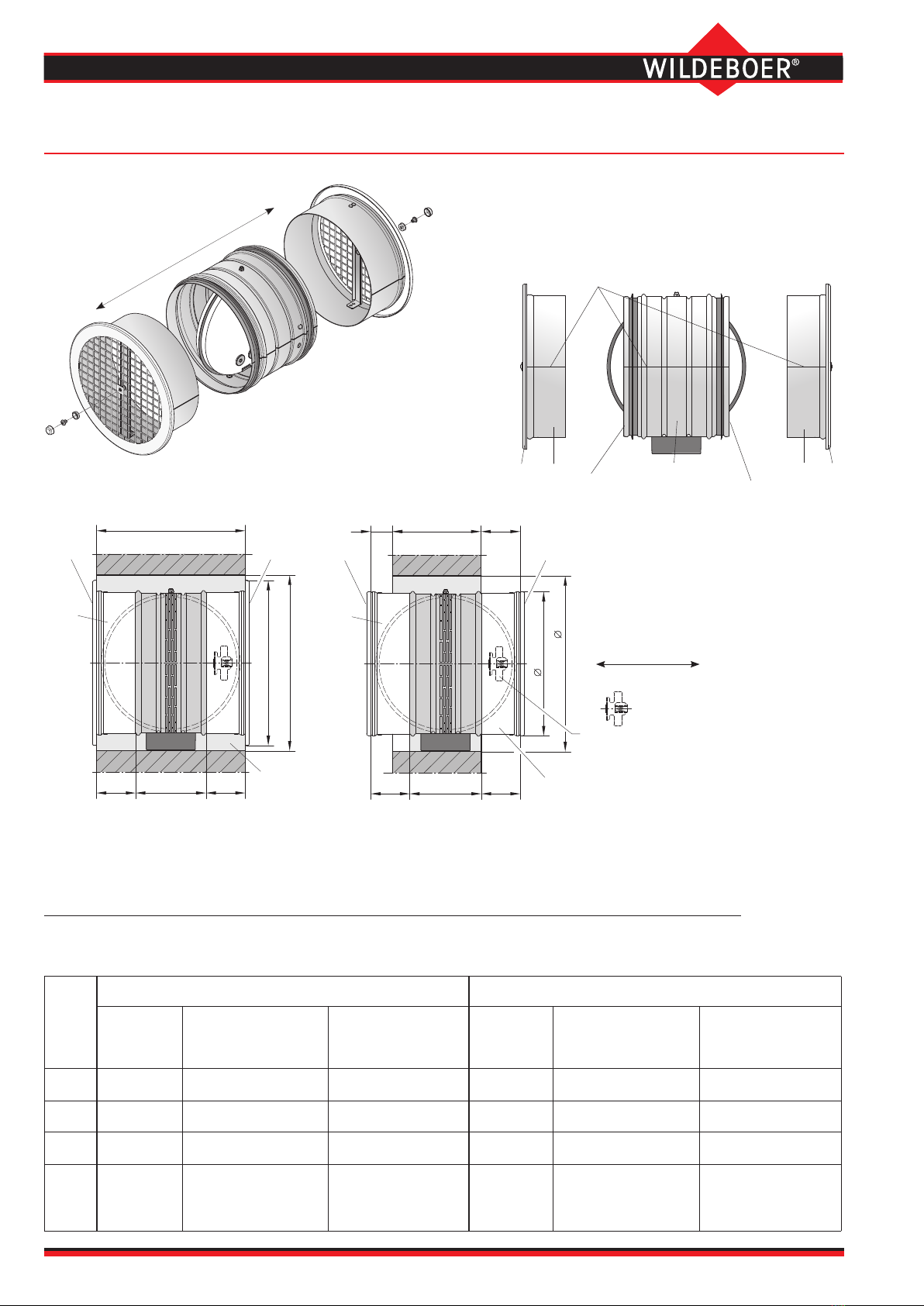

1 Casing

2 Damper blade

3 Damper blade seal

4 Release element with

pipe fusible link 70°C

5 Fusible link holder

on the casing

6

Enclosed

closing spring actuator

7 Bearing axis

8 Plug connection with

lip seal

9 Limit switch (optional)

10 Fusible link holder on

damper blade

DN

Fire damper Protective

grille

Afree

[m2]

∅ d

[mm]

U

[mm]

AA

[m2]

Afree

[m2]

Weight

[kg]

100 99.3 00.0068 0.004 0.565 0.0049

125 124.3 00.0110 0.008 0.685 0.0081

160 159.3 5 0.0185 0.014 0.865 0.0138

200 199.3 25 0.0293 0.024 1.105 0.0221

250 249.3 50 0.0465 0.038 1.715 -

315 314.3 85 0.0747 0.064 2.415 -

Maintenance-free FR90 re dampers according to EN 15650: FR92K series, short length 150 mm

Fire classication: EI 30/60/90/120 (ve- ho, i ↔ o) S

Declaration of performance: DoP no.: CPR/FR90/003

• FR90 re dampers are essentially made from non-combustible building

materials. Certication: Certicate MPA-BS 6000/593/18

•Use in air transfer applications is based on compatibility for approval in accordance

with the building code in each individual case. Approvals are no longer issued.

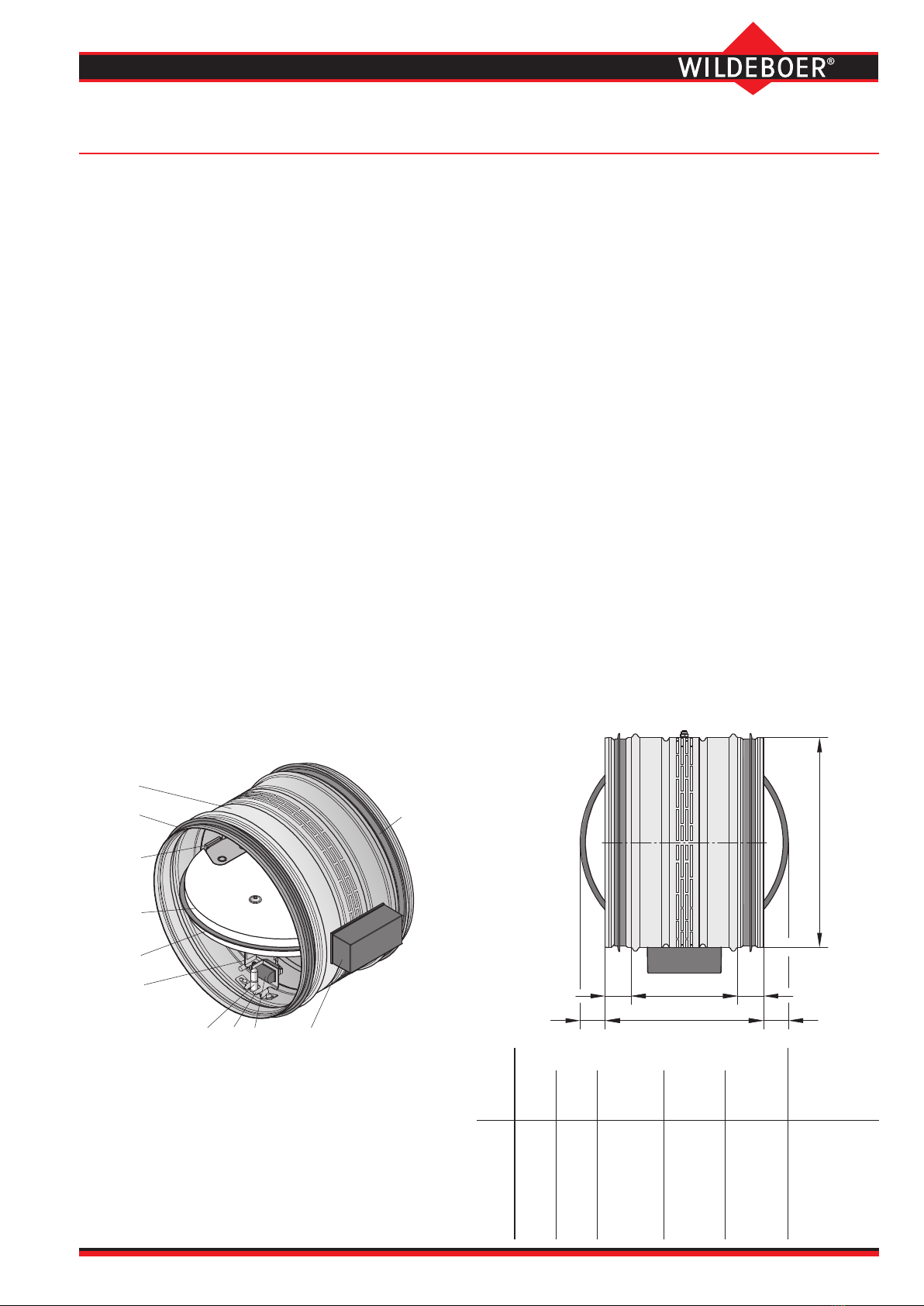

Optional accessories:

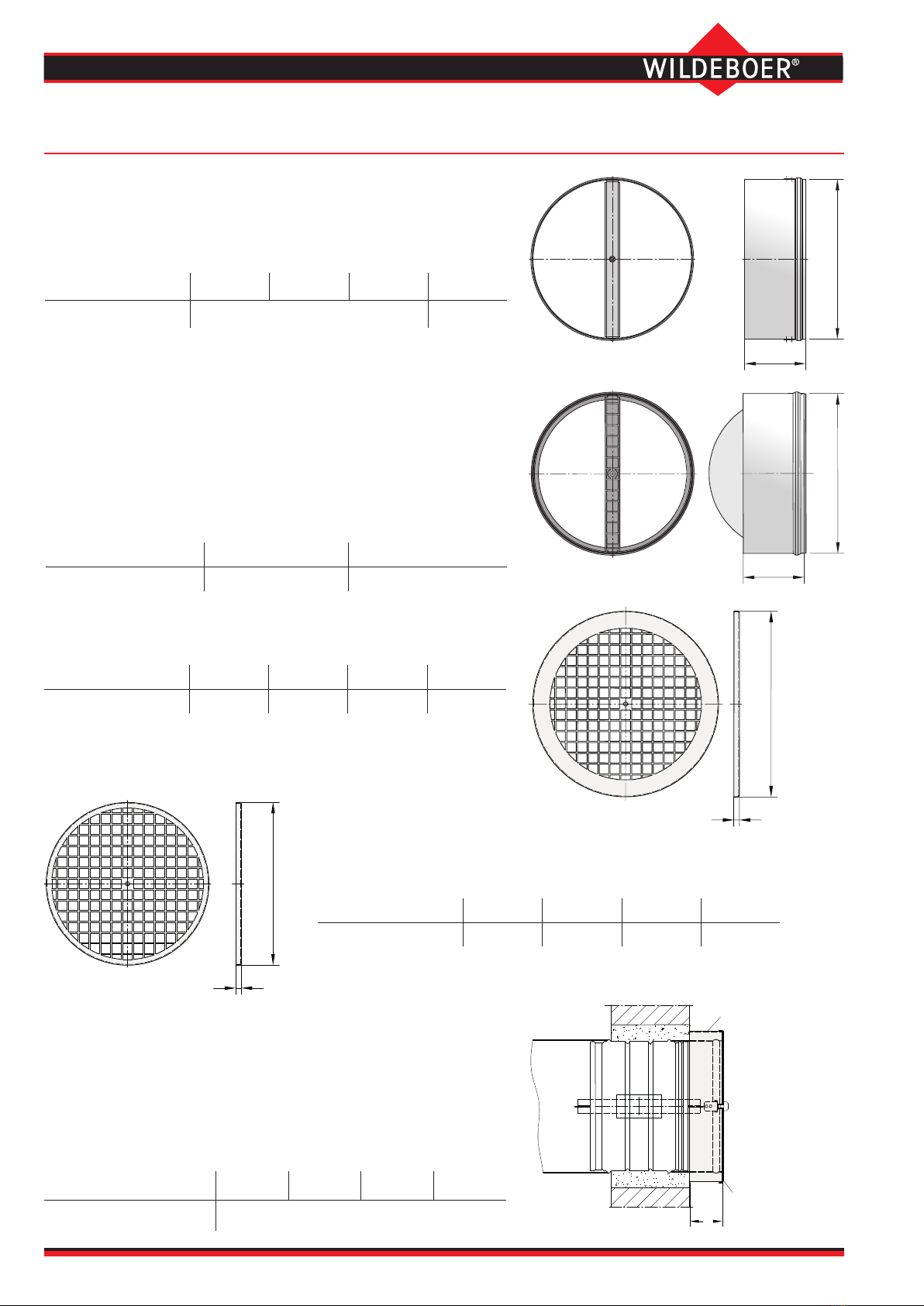

•Connecting piece AS with traverses for screw fastening

the protective grille SG1 or SG2 to the operation side

L1 or non-operation side L2. Sizes DN 100 to DN 200.

⇒ see pages 2 and 8 to 10

• Connecting piece AR with non-return valve and trav-

erse for screw fastening the protective grille SG1 or SG2

on the non-operation side L2. Sizes DN 160 to DN 200.

⇒ see pages 2, 8 to 10

•Protective grille SG1 with wide edge for installation

ush with the wall or in combination with the duct frame

RB. Sizes DN 100 to DN 200.⇒ see pages 2 and 8 to 10

•Protective grille SG2 with narrow edge for installation

ush with the connecting piece AS. Sizes DN 100 to

DN 200. ⇒ see pages 2, 8 to 10

•Duct frame RB for covering connecting piece and pro-

tective grille SG1 which protrude from the wall. Sizes

DN 100 to DN 200. ⇒ see pages 2 and 8 to 10

Single-piece casing made of galvanized sheet steel with

plug connections and lip seals on both sides.

Release element for 70°C nominal temperature.

Casing leak tightness class C according to EN 1751.

Enclosed, maintenance-free drive mechanism outside

the casing wall, sealed drive axles made of stainless

steel, with red metal bearings.

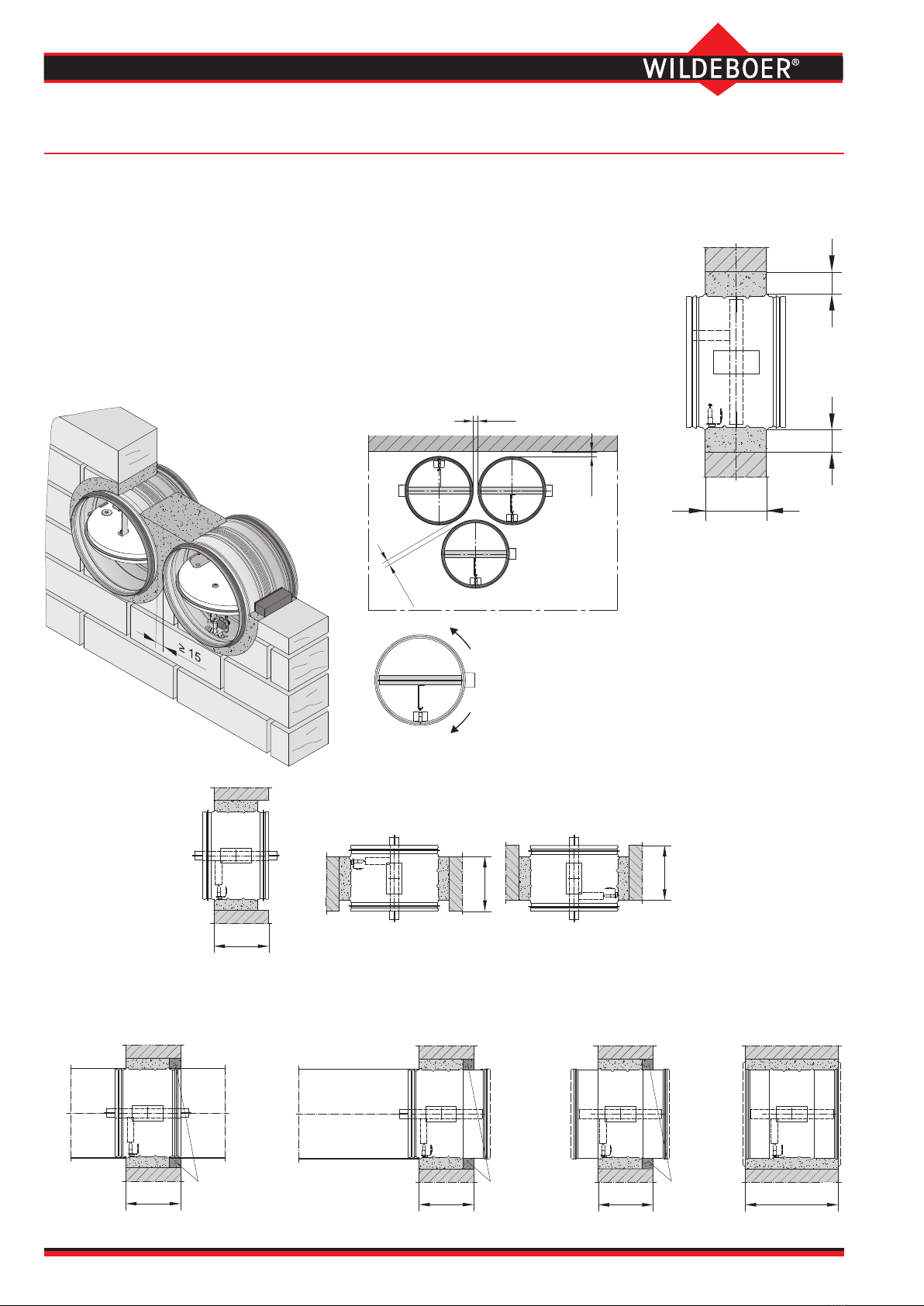

For installation in rigid walls and ceilings with a thickness

of at least 100 mm and in metal stud walls with a thick-

ness of 95 mm or more. Installation can be carried out

with the damper blade axis in the vertical or horizontal

position, or anywhere in between. Installation with the

connecting piece AR and non-return valve must be in a

vertical axis position.

Connection to ventilation ducts made from non-combus-

tible or combustible materials, or with protective grille.

Optional accessories:

•

Limit switch for damper blade position CLOSED. ⇒ see page 11

Nominal sizes DN [mm]

100 - 125 - 160 - 200 - 250 - 315