User Manual 5.02 (2016-10) 3Subject to change Series FK120

FK90 re dampers

Description

Increased corrosion protection through powder coating and stainless steel

Casings coated internally and externally are recommended:

•

metal frames of the damper blades made of 1.4301 stainless steel and

– if present – the metal cover as well

•

thermal-mechanical release mechanisms with corrosion-resistant (coated) release element 70°C.

These combinations allow additional corrosion protection for harsh service conditions.

FK90 re dampers

•

Meet the hygiene requirements according to VDI 6022-1, DIN 1946-4 and DIN EN 13779

•Do not promote the growth of microorganisms 1) (fungi, bacteria).

This reduces the risk of infection for people and also the necessary

cleaning and disinfection work!

•Are resistant to disinfectants 2)

•Are suitable for use in hospitals and similar facilities!

•

Permanently perform their function under high corrosion condi-

tions.Tested according to EN 15650, annex B with 20% saline solution.

1) The corresponding resistance of the materials to fungi and bacteria was veried by testing the microbial metabolic potential under

DIN EN ISO 846 for all materials in the FR90 re dampers.

2) The resistance to disinfectants of the materials in the FR90 re dampers was tested with the disinfectant groups of active ingredients alcohol and

quaternary compounds. These disinfectants are on the list by the Robert Koch Institute, and were used in accordance with the specications in

the list of disinfectants by the Disinfectants Commission in the German Association for Applied Hygiene (VAH). It has been veried that FR90 re

dampers can withstand normal use of disinfectants and disinfection methods.

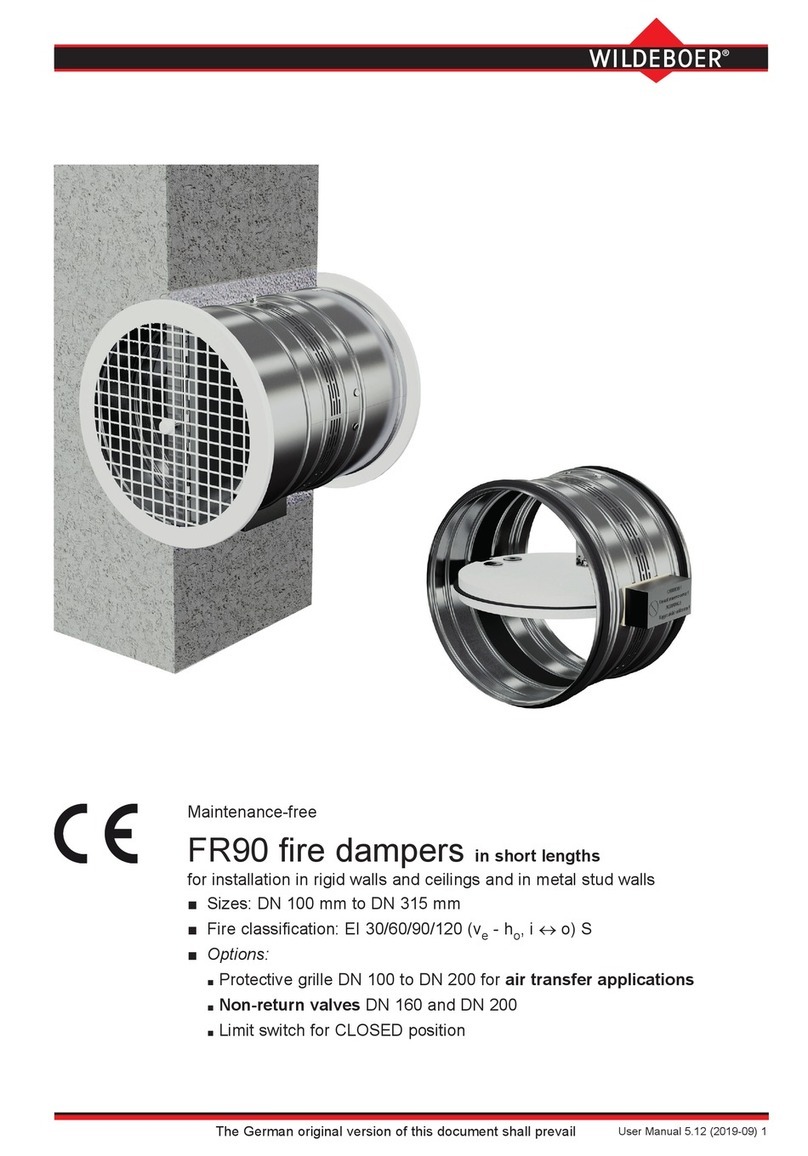

Pressure-joined casing with all-round single-piece design,

made of galvanized sheet steel, leak tightness class C

according to EN 1751. Formed connection anges, outer

beading and tapered inner beading ensure stability, free-

dom of damper blade movement, minimum pressure drop

and low noise level.

Option: Casing with epoxy resin powder coating.

Replaceable damper blade made of high-temperature-re-

sistant, corrosion-resistant and abrasion-proof calcium

silicate with galvanized metal frame and folded, wear-re-

sistant elastomer lip seals.

Options: Damper blade with metal frame made of 1.4301

stainless steel/damper blade with metal cover made of

galvanized steel/damper blade with metal cover made of

1.4301 stainless steel.

Fully enclosed, maintenance-free slider crank transmis-

sion in the area of the casing wall, as a self-locking drive

mechanism for break-proof torque transmission. Sealed

drive axles made of stainless steel, with red metal bea-

rings.

Thermal release mechanisms for 70°C, 95°C and 100°C

nominal temperature. The operation units can be actua-

ted manually or electrically.

⇒ see pages 4 and 5

Release mechanisms, operation units and electric actu-

ators are enclosed and tted with a spring return. They are

maintenance-free, can be connected in a form-locking or

force-tting manner, are easy to replace and can be easily

retrotted as required.

For installation with horizontal or vertical damper blade

axles. Air inow from any connection side. Connection to

ventilation ducts made of non-combustible or combustible

materials, including protective grilles.

Option: Additional openings on the operation side in the

casing.⇒see page 14

Widths B: 200 mm to 1500 mm | 200 mm to 1000 mm

Heights H: 200 mm to 800 mm | 200 mm to 1000 mm

Lengths: 400 mm and 500 mm

The respective width and height dimensions are available

in 5-mm increments and can be combined. ⇒ see page 14

For installing in rigid walls, ceilings and in metal

stud walls. ⇒ see pages 11 and 12

Maintenance-free FK90 re dampers according to EN 15650

Fire classications: EI 30/60/90/120 (ve- ho, i ↔o) S C10ooo ⇒see page 11

Declaration of performance: DoP no.: CPR/FK120/002

EU Declaration of Conformity according to Directive 2014/34/EU

for use in potentially explosive atmospheres

Environmental Product Declaration ISO 14025, EN 15804: EPD-WWB-20130081-IBA1-DE