WILHELM KELLER GmbH & Co. KG

Herdweg 1 · D-72147 Nehren · phone: +49 (0)74 73 9449-0 · fax: +49 (0)74 73 9449 49

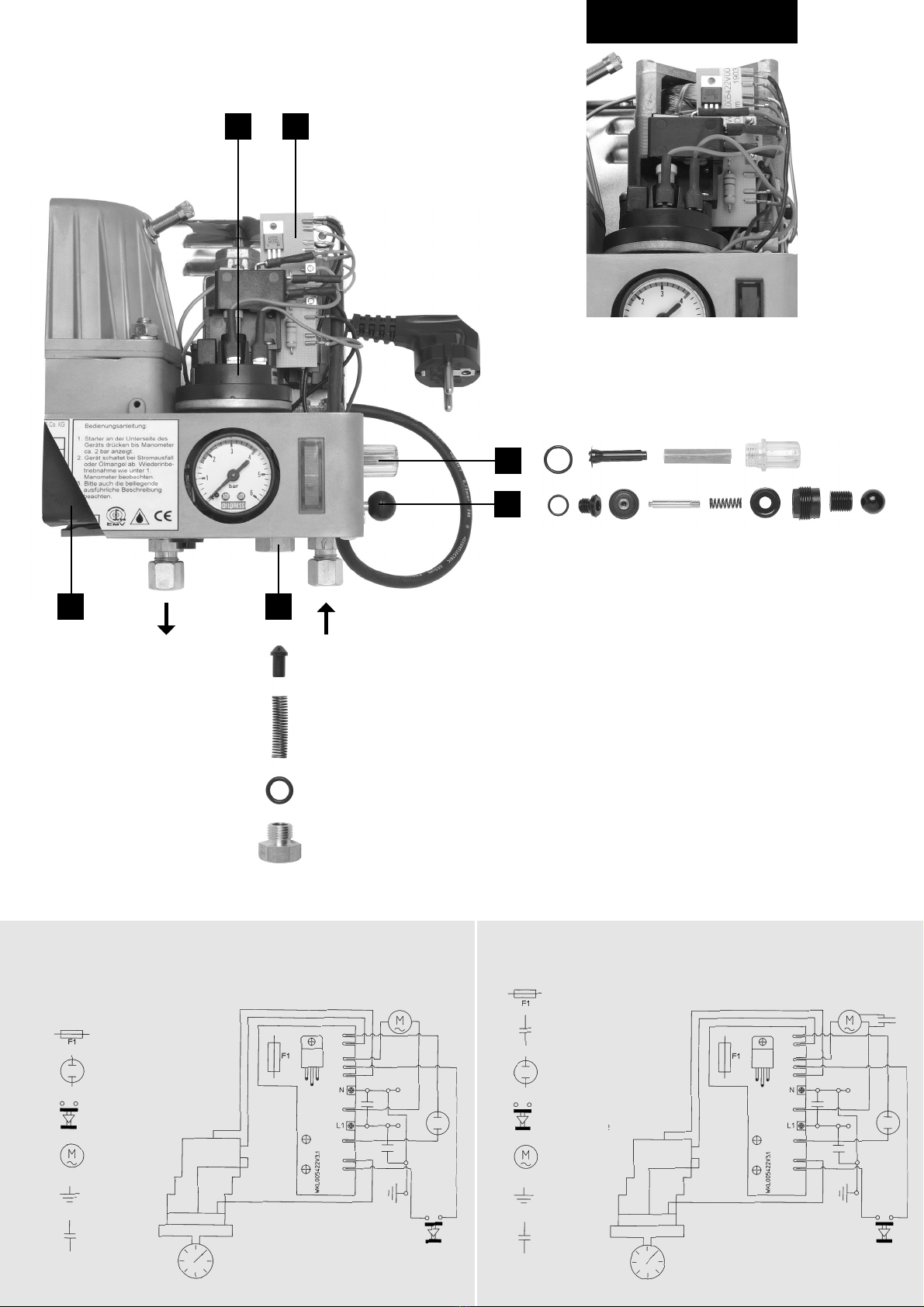

Test, over-pressure and

drain valve

The test, over-pressure and drain valve is the

cut-off point between the supply line and

suction line. When opened, it connects the

pressure and suction areas. No non-return

valve may therefore be installed in the

suction line. The over-pressure valve comes

into operation when the maximum set pres-

sure of 4 bar is exceeded. The proper

operation of the valve can be checked by

actuating it manually. It also enables the

pressure to be relieved in the complete

piping system and the storage vessel, and

the draining of the unit via the suction line.

Non-return valve

The non-return valve is fitted by means of

the plug screw. This prevents return flow or

loss of pressure in the oil already pumped

into the pressure storage vessel and the

supply line. To ventilate the unit, the plug

screw is removed complete with the non-

return valve.

Pressure switch

The pressure switch switches the motor on

at a lower working pressure of approx. 1.6

bar, and switches it off again on reaching the

upper working pressure of approx. 2.6 bar.

The pressure range can be regulated upward

in the case of supply heights of over 15 m.

This is done by screwing in the pressure set-

ting screw, using a small screwdriver or

small pin of max. 1.5 mm diameter in the

four slots of the pressure setting screw. The

safety cut-off must in this case be adjusted

to the lower working pressure of minus 0.1

bar. The pressure for the safety cut-off is

reduced by screwing the cross-head screw

in, and increased by screwing it out. In the

event of a drop in pressure to below the set

pressure as a result of a power failure, lack

of oil or break in the line, the safety cut-off

switches to “fault”, and the control lamp

lights up.

The installation, connection and testing of

heating oil supply systems must be carried

out in accordance with DIN 4755 Part 2. The

unit can be installed up to 1.5 m below the

upper tank level. The maximum suction head

of 3 m must not be exceeded. About 1.0 m

of suction head must be deducted for every

10 m of horizontal suction distance.

Example:

Calculating the suction head

Tank floor - unit = 1.5 m W1.5 m vertical

Horizontal = 2.0 m W0.2 m vertical

suction distance

Calculated suction head 1.7 m

The unit is mounted horizontally against the

wall. The unit is easy to adjust by means of

the movable assembly plates.

The leak detection system LS 1 (Art. No.

800.912) with collecting trough must be

mounted under the device.

If the pressure storage vessel is operated

with a double-walled safety tank or a GFK

tank, the pressure relief valve DV 1 (Art. No.

754.912) must be installed in conjunction

with leak detection system LS 1.

Suction line

The installation of a filter in the suction line is

not necessary, since a filter of adequate

capacity with a mesh size of 0.1 mm is already

built into the unit. The suction line should ter-

minate at least 5 cm above the tank floor.

No non-return valve may be

installed in the suction line.

The tank connection 041.912 for individual

tanks fulfils this requirement. In the case of

normal suction lines for plastic PE and PA

battery tanks, the rocker-lever non-return

valves must be replaced by rocker-lever

shut-off valves. In the case of OILPRESS

suction lines, rocker-lever shut-off valve can

be ordered under article no. 594.912.

Supply line

OILPRESS pressure storage units allow the

use of a single-line supply system (see

Piping diagram). The line can be laid in any

way required. Oil pressure regulators must

be installed so that the permissible pressure

range of the oil regulator of 125 mm – 3000

mm of oil is not exceeded at the combustion

point. The line from the oil pressure regulator

to the oil regulator should be laid at an

incline. When used for the supply of atomis-

ing burners, the user must check whether a

pressure regulator should also be installed.

178.822/07/15

The installation and maintenance instructions

are intended only for qualified technicians!

1. Open all valves in the system, including

the inlet valve at the oil regulator.

2. Insert the plug into the socket. The control

lamp will light up.

3. Unscrew the plug screw with the complete

non-return valve .

4. Press down the push button on the

underside of the unit until oil flows without

air bubbles.

5. Refit the plug screw with the complete

non-return valve .

6. Press down the push button until the

pointer of the manometer has reached the

green area (this may take up to 10 min.).

The unit then starts to operate automatical-

ly. On reaching the upper cut-off pressure

(approx. 2.6 bar), the unit switches off.

7. For testing purposes, the button of the

over-pressure valve is now slightly

withdrawn until the motor starts again.

Note the starting pressure, which should

be approx. 1.6 bar.

following lack of oil or power failure

Check whether the manometer is still

showing any pressure, and if so, press the

starter button until the motor continues to

run automatically. If the manometer shows

no pressure, restart as described under

“Starting and ventilation”.

The installation and electrical connection of

the unit, commissioning and maintenance,

must be carried out by a qualified technician.

In the event of maintenance work, and before

removing the cover hood, the unit must be

disconnected from the power supply by

removing the plug, and the pressure in the

pressure storage vessel must be relieved.

The operating instructions must be kept in

the vicinity of the system following installation.

An essential requirement for smooth opera-

tion of the pressure storage units is proper

installation in accordance with the technical

rules applicable to the planning, installation

and operation of the complete system.

The pressure storage units and the corre-

sponding pipes must be installed so that

they are protected against frost.

Heating oil is a material harmful to water.

Spilt or leaked heating oil must be disposed

of properly. All components which have

come into contact with heating oil must be

disposed of properly in accordance with

applicable disposal regulations.

This device is not intended for use by people

(incl. children) with restricted physical, sen-

sory or intellectual abilities or lack of expe-

rience and/or lack of knowledge, unless they

are supervised by a person responsible for

their saftey or received, from this person,

instructions about how to use the device.

Children should be supervised to ensure that

they do not play with the device.

If the device’s power cable is damaged it

must be replaced by the manufacturer or the

manufacturer’s customer service or a simi-

larly qualified specialist.

Pressure setting

screw

Cross-head screw

E

F

B

Installation Starting and ventilation

F

F

E

Restarting

Instructions

Maintenance work

Replacing the filter

In case of contamination and during mainte-

nance work, the filter should be replaced, in

order to ensure trouble-free operation.

D