6 )

USER/STUDENT DIRECTIONS

Student Account

Prepare to Weld

1. Connect the guideWELD VR workstation to a computer with VR software installed

2. Select the welding gun (MIG or Stick)

3. With the workstation powered o, attach the selected welding gun

4. Power on the workstation and launch software and login with Student Account

information. Note: The default password is “PASSWORD”

5. Determine the coupon (tee, lap or butt joint) to be used for the assignment and

place chosen coupon on the workstation

6. In the main Student Screen, choose an assignment and click on the Practice button.

Chosen assignment should match welding gun and coupon

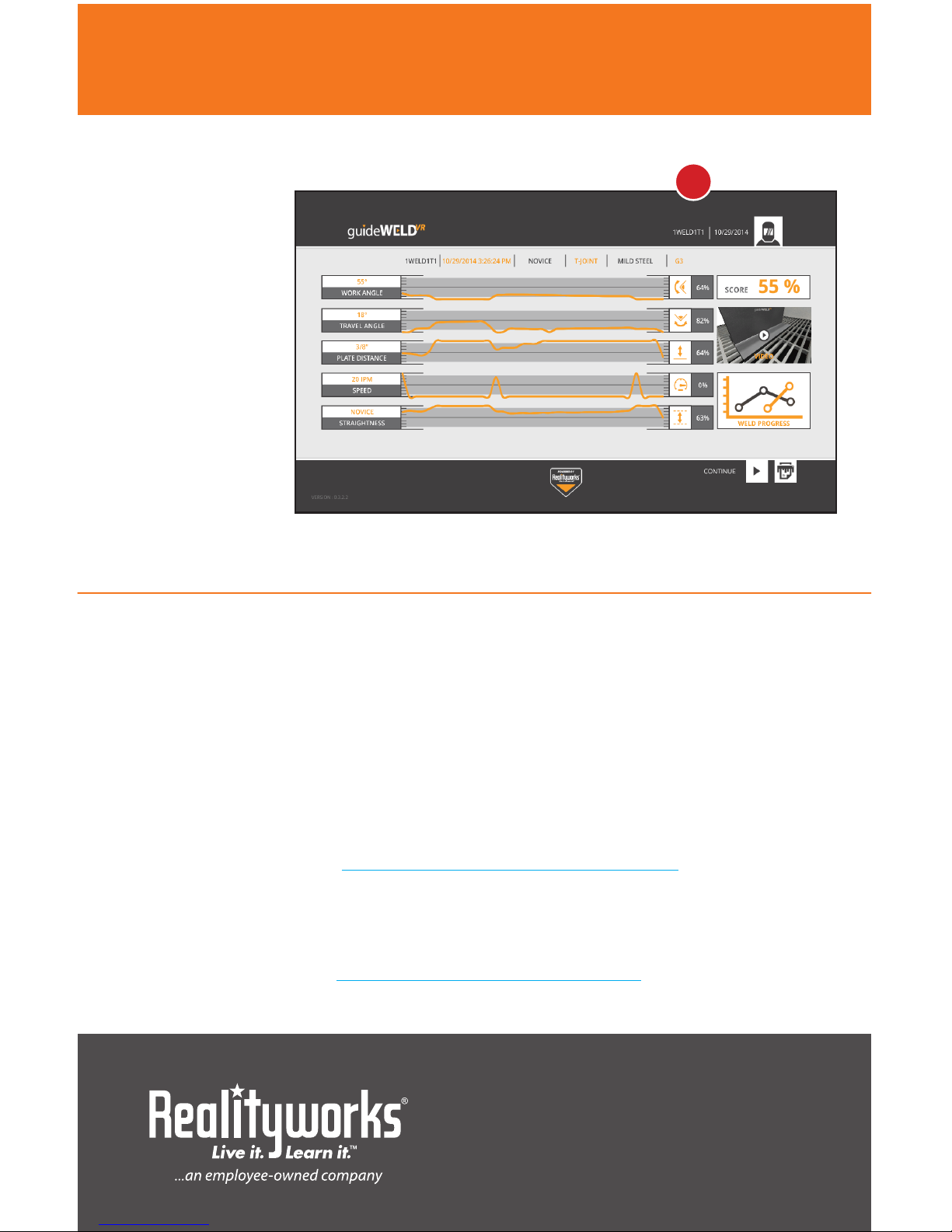

Test vs. Practice Mode

Practice mode allows use of the technique guides, while Test mode does not. Test

mode is available only after a student achieves a grade of 50% or higher while in

Practice mode.

Optional corrective technique guides include:

Note: An equal sign will display when performing proper technique

1. WORK ANGLE: TOP LEFT CORNER – if an up arrow shows, move the butt

of the welding gun up. If a down arrow shows, move the butt of the gun

down. The nozzle or tip of the electrode should remain on path (Fig. 6A)

2. TRAVEL ANGLE: TOP RIGHT CORNER – if a right arrow shows, tilt the

gun to the right. If a left arrow shows, tilt the gun to the left. (Fig. 6B)

3. SPEED: IN FRONT OF WELDING GUN AND COUPON – displays the

travel speed and gives a plus sign when speed should increase and

a minus sign when speed should decrease (Fig. 6C)

4. NOZZLE TO PLATE DISTANCE: ON WELDING NOZZLE/ELECTRODE –

displays correct distance from the work coupon and the gun nozzle.

If positioning is correct, a green circle will appear, while a red arrow

will appear when out of position (Fig. 6D)

5. STRAIGHTNESS: ABOVE AND BELOW THE METAL – the dotted line

shows right location on the work coupon (Fig. 6E)

Tacking the Coupon (prior to each weld)

Tacking the coupon needs to be complete on the main welding screen

1. Ensure the message TACK LEFT SIDE OF PLATE AS SHOWN is displayed

2. Bring the physical welding gun into the same position as the virtual welding gun

shown on the screen. The nozzle of the MIG gun or tip of the electrode of the Stick

gun must be centered on the far left edge touching the coupon, with the same

work angle as the virtual welding gun (Fig. 7A)

6A

6B

6C

6D

6E