WILKINS, a ZURN company

1747 Commerce Way, Paso Robles, CA 93446 Phone:805-238-7100 Fax:805-238-5766

3

DIAPHRAGM MOVEMENT CHECK

1. The diaphragm movement check can be determined during

the diaphragm check or it can It can also be performed with the

use of a valve position indicator model ZPI.

2. Replace cover plug and open pilot ball valves on inlet and cover.

3.Closingtheoutletisolationballvalveswilldirecttheowto

the cover causing it to close. NOTE: Slow or delayed closing

of main valve is normal and is due to the time requirements

to ll, pressurize cover, and stretch the diaphragm into the

closed position. This normal delay is not mechanical bind-

ing of the valve assembly.

4. Using the valve position indicator, make note of the closed

position on the indicator. Compare distance of the open mark to

the close mark and compare to Table 3.

5. Verify that the main valve is closed, by opening a down-

stream source (not the outlet isolation ball valve on the main

body).Ifwatercontinuouslyows,thenthemainvalveisnot

sealing properly. Double check the valve movement matches

the values in Table 3 and refer to the disassembly procedures

section if it does not. This is an indication that the main valve

is not sealing due to an obstruction between the seat and

thesealoradamagedseal.Ifwaterdoesstopowingand

the measured valve movement does not match Table 3, then

there is possible damage under the cover. Remove cover to

identify obstruction and replace parts as necessary

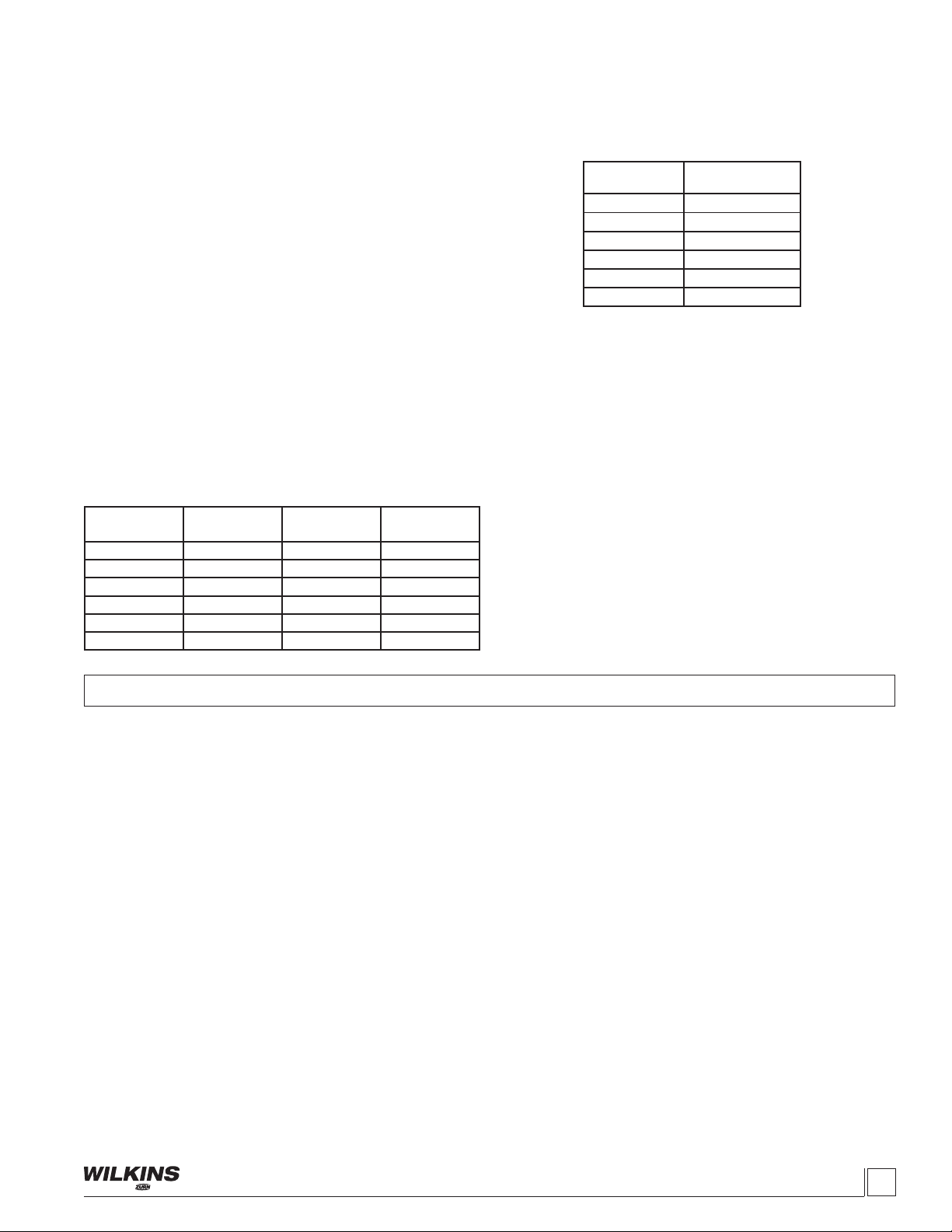

TABLE 3. VALVE STEM TRAVEL

VALVE SIZE

(in)

VALVE SIZE

(mm)

STEM TRAVEL

(in)

STEM TRAVEL

(mm)

2" 50 0.7 18.0

2-1/2" 65 0.8 21.3

3" 80 0.9 23.4

4" 100 1.1 28.8

6" 150 1.7 43.4

8" 200 2.4 59.7

6. For smaller valves (6” and below) diaphragm checks can

be performed by hand with the use of a valve stem tool. The

valve stem tool can be made using Table 4 to create a “T” bar

handle with the appropriate threads on the opposite end of the

“T” handle.

TABLE 4. VALVE STEM THREAD SIZE

VALVE SIZE

(in)

THREAD SIZE

UNF INTERNAL

2" 10 - 32

2-1/2" 10 - 32

3" 1/4 - 20

4" 1/4 - 20

6" 3/8 - 20

8" 3/8 -16

7. To perform the diaphragm check using the vale stem tool,

rstremoveallpressureinthesystemandventthecover.

Then remove the center plug on the cover and insert tool into

the top of the stem threads. Once the tool is inserted, the

valve can be lifted up and the valve movement can be mea-

sured by creating marks on the tool in the opened and closed

positions. The distance between marks is the valve stem

travel. Replace or repair any parts as necessary.

SEAL CHECK

1. To check the seal of the valve disc, an additional pressure

gauge will be needed downstream of main valve.

2.Withthevalveowing,slowly,closepilotoutletballvalves

to apply pressure to cover and allow to close.

3. Open downstream source and monitor the pressure on the

inlet and installed outlet gauge, for one min. The pressure on

the outlet side should remain zero. If the pressure matches inlet

pressure or increases, the main valve is leaking or the outlet

ball valve on the pilot system is allowing pressure to creep by.

Either way it is recommended that the valve be disassembled

and inspected (refer to “Disassembly” section).

Maintenance Instructions

PREVENTATIVE MAINTENANCE

The Zurn Wilkins ZW200 models require minimal maintenance.

However, it is highly recommended to schedule annual inspec-

tions and to have a repair kit on hand before work begins.

DISASSEMBLY

Warning: Because of the ability to perform inspections and

maintenance without removal from the system, it is very

important that all shut off valves be closed and all pressure

relieved in the valve before beginning disassembly. Failure

to do so can result in personnel injury or equipment damage.

1. Verify that all pressure sources are closed up and down-

stream of valve.

2.Removepressureinpilotsystembylooseningthetubet-

tings to the valve body and cover. When all pressure has been

vented, continue to disassemble the pilot control valve and

cover tubing. NOTE: Taking a picture before tear down can help

with re-assembly of pilot system.

3. Next remove the cover by loosening and removing the

cover bolts. If the cover does not come off easily it may be nec-

essary to loosen the cover using a brass chisel and rubber mal-

let. Apply the chisel under the cover pointing upward away from

valve body and tap bottom of cover with the chisel and mallet to

loosen the cover. Once the cover is loose, pull cover straight up

to avoid damaging the stem and stem bearing in the cover. On

larger valves 8” and up, eye bolts and a hoist are recommended

due to the weight of these larger covers.

4. With the cover removed the diaphragm assembly can be

removed. To avoid damaging the seat bushing, grab the stem

and lift straight up. For larger valves 8” and up it is recommended

that an eye bolt with the proper stem threads be used with a

hoist to lift the assembly out of the valve (see Table 4 for ap-

propriate stem threads).

5. Next it is recommended that the diaphragm assembly be

placed in a vise with the bottom hex nut secured. Once secured

remove the spring and stem nut. While removing the nut inspect

the stem threads. Clean stem with a wire brush if mineral de-

posits or corrosion are present.

6. After inspecting the stem and removing the nut the diaphragm

assembly can be dismantled. If the valve has not been serviced

in awhile it is possible that the assembly will require the use of a

rubber mallet or pry bars to dismantle the assembly. If this is the

case gently tap or pry the components until the components are

free to move. When disassembling be sure to clean, inspect, and

save all components. Replace any damaged components as

necessary.

7. The last component to inspect is the seat which is in the body

of the main valve. During inspection of the seat, clean and polish

asnecessarywithnegritwet/drysandpaper(400gritorhigher).

Typically, if after cleaning there is no visual damage or excessive

wear the seat should not require removal. If damage is present

or the seat is excessively worn the seat should be replaced.