Installation and operating instructions Wilo-DrainLift S 29

PRODUCT DESCRIPTION English

The lifting unit must not be used for pumping

• Debris, ash, garbage, glass, sand, plaster, cement,

lime,mortar,brousmaterials,textiles,paper

towels,wet‑wipes(e.g.eececloths,moisttoilet

paper wipes), nappies, cardboard, coarse paper,

synthetic resins, tar, kitchen waste, grease, oil

• Slaughterhouse waste, disposal of slaughtered

animals and animal waste (liquid manure, etc.)

• Toxic, aggressive and corrosive substances, such

as heavy metals, biocides, pesticides, acids, bases,

salts, swimming-pool water

• Cleaning agents, disinfectants, dishwashing or

laundry detergents in excess amounts, and such

which have a high degree of foam formation

• Sewage from drainage objects which lie above the

backowlevelandcanbedrainedbymeansof

gravity(acc.toEN12056‑1)

• Explosive media

• Drinking water

be used.

The system must be installed in accordance with

thegeneralrulesasdetailedinEN12056and

DIN1986‑100.

Intended use includes compliance with this man-

ual. Any other use is regarded as non-compliant

with the intended use.

3.1.1. Application limits

DANGER due to overpressure

Exceeding the application limits can result in

excessive pressure in the collection reservoir

if the unit malfunctions. This can cause the

collection reservoir to burst! There is a health

risk due to contact with sewage polluted by

bacteria (faeces). Always comply with the

application limits and ensure that the inlet is

blocked if the unit malfunctions.

The following application limits must be observed

strictly:

• Max.intake/h:600l

The maximum inow must always be less than

the volume ow of the pump at the respective

duty point.

• Max.suctionhead:5m

• Max.permittedpressureinpressurepipe:1.5bar

• Max.uidtemperature:40°C,60°Cformax.

3min

• Max.ambienttemperature:40°C

• Operatingmode:S315%,120s

The unit is not designed for continuous duty!

The maximum volume ow applies to intermit-

tent periodic duty according to EN60034-1!

• Also comply with further information in the

“Technical data” section!

3.2. Set-up

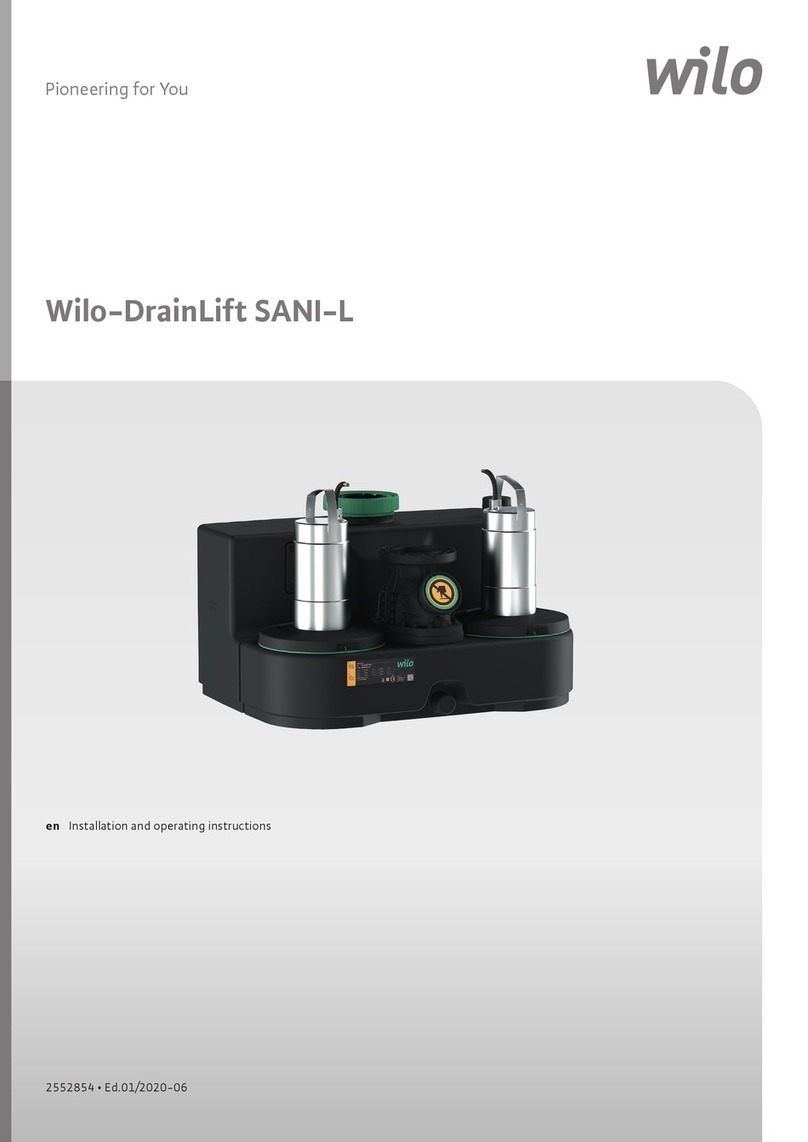

The Wilo-DrainLift S is a submersible, fully

automatic sewage lifting unit that is ready for

connection as a single-pump system.

Fig. 1: Description

1 Collection reservoir 6 Inlet DN 40

2 Inspection opening 7 Ventilation connection

3 Level control 8 Pressure connection

4 Motor 9 Fastening straps

5 Free choice of inlet surface areas

3.2.1. Collection reservoir

Gas and water-tight collection reservoir made

from PE plastic with tapering collection chamber

for reliable operation without any build-up of

deposits.

TheinletconnectionsDN100canbeselectedas

required on both sides and on the longitudinal

side.ThepressureconnectionDN80iscongured

vertically above the reservoir. Furthermore, the

liftingunithastwoinletconnectionsDN40and

oneventilationconnectionDN70.

For simple maintenance of the unit, the collection

reservoir is equipped with an inspection opening.

Furthermore, the reservoir also has two fastening

straps. This allows the lifting unit to be anchored

in an anti-buoyant way to the ground with the

suppliedxationmaterial.Thefasteningstraps

also function as transport carrying handles.

3.2.2. Motor

The motor that is mounted is a watertight,

encapsulated dry motor with a stainless steel

housing. The cooling is done by the ambient air.

The waste heat is given off via the motor housing.

The motor is equipped with a thermal winding

monitorwithbimetallicstrips:

• The winding monitoring for the three phase

motor is displayed and reset via the connected

switchgear.

• The winding monitoring for the AC motor is au-

tomatically switching. This means that the motor

is switched off if it overheats and is automatically

switched on again when it has cooled down.

3.2.3. Level control

Thelevelcontrolisttedinthecollection

reservoir.Rodoatswitchesareusedassignal

transmitters. The switching points for “Pump ON”

and “High water alarm” are pre-set. The switch-

ingpointfor“PumpOFF”isdenedbytheset

follow-up time of the pump.

3.2.4. Switchgear

Thesystemiscontrolledviathettedswitchgear.

The switchgear can also be used to implement

a collective fault signal (SSM). The cable length

from the motor to the switchgear is 4 m and from

switchgear to plug 1.5 m. Detailed information

about the switchgear can be found in the en-

closed installation and operating instructions.

For exact details on connection, see the con-

nection diagram in this operating and mainte-

nance manual.