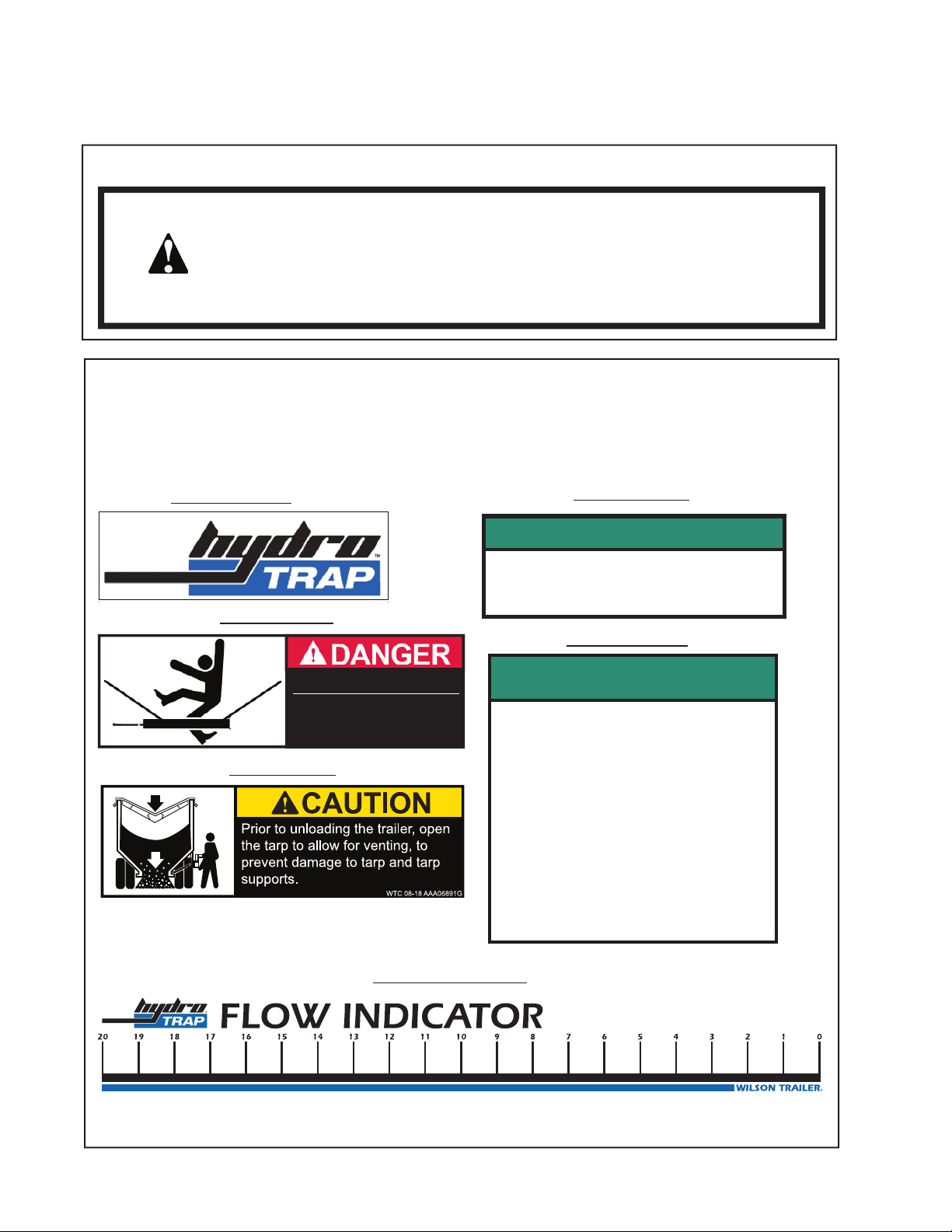

HYDRO-Trap Operator’s Manual

Operation 3-5

INSPECTION

HYDRO-Trap System Inspection

Perform all inspections in order: No power to trailer; Add 7-way power; Add dual conductor

power.

This inspection assumes the common installs having a Shur-Co 4500 power tarp with a Smart

3 control module, electrical connections are Grote bullets or Deutsch connectors, tractor

has 120 amp kit installed with 120 circuit breaker and disconnect switch, and a Kar-Tech

receiver and KTI hydraulic pump unit installed in the apex of the trailer. Older units may have

connections with crimped bullet connections covered with heat shrink. Several models may

have the receiver and hydraulic power unit mounted over the kingpin.

Inspection Step 1: No Power to Trailer

Tractor power supply and connection to trailer

Disconnect the tractor 7-way and dual conductor cables from the trailer to perform the initial inspection.

Test the 7-way cable voltage output between the center pin auxiliary/ABS power and the ground pin. The

ground pin is the largest of the seven and at the top of the connection.

Test the voltage output of the dual conductor cable. Confirm the 120 amp circuit breaker is installed and is

in the set position. Confirm the main power disconnect switch is on. Both the 120 amp circuit breaker and

disconnect switch must be connected to the positive terminal with the circuit breaker closer to the battery.

Inspect disconnect switch, circuit breaker, connections, plugs, and cables for corrosion.

Front of trailer; outside

Examine the 7-way and dual conductor connections at the front of the trailer for debris buildup, corrosion,

deflected or loose pins, or other damage. Clean corrosion or debris buildup from connectors. Examine the

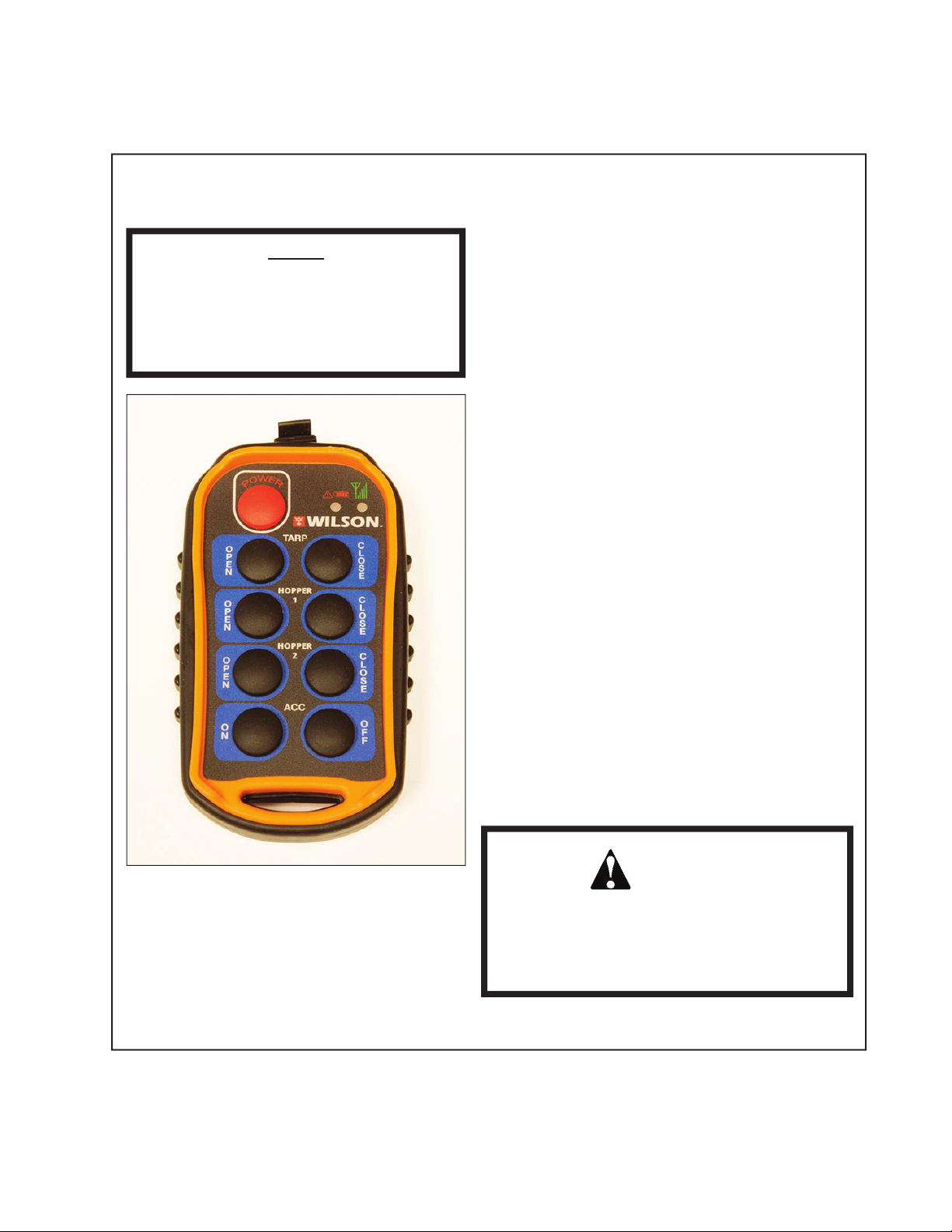

tarp module for damage. Depress open and close button functions for feel of operation.

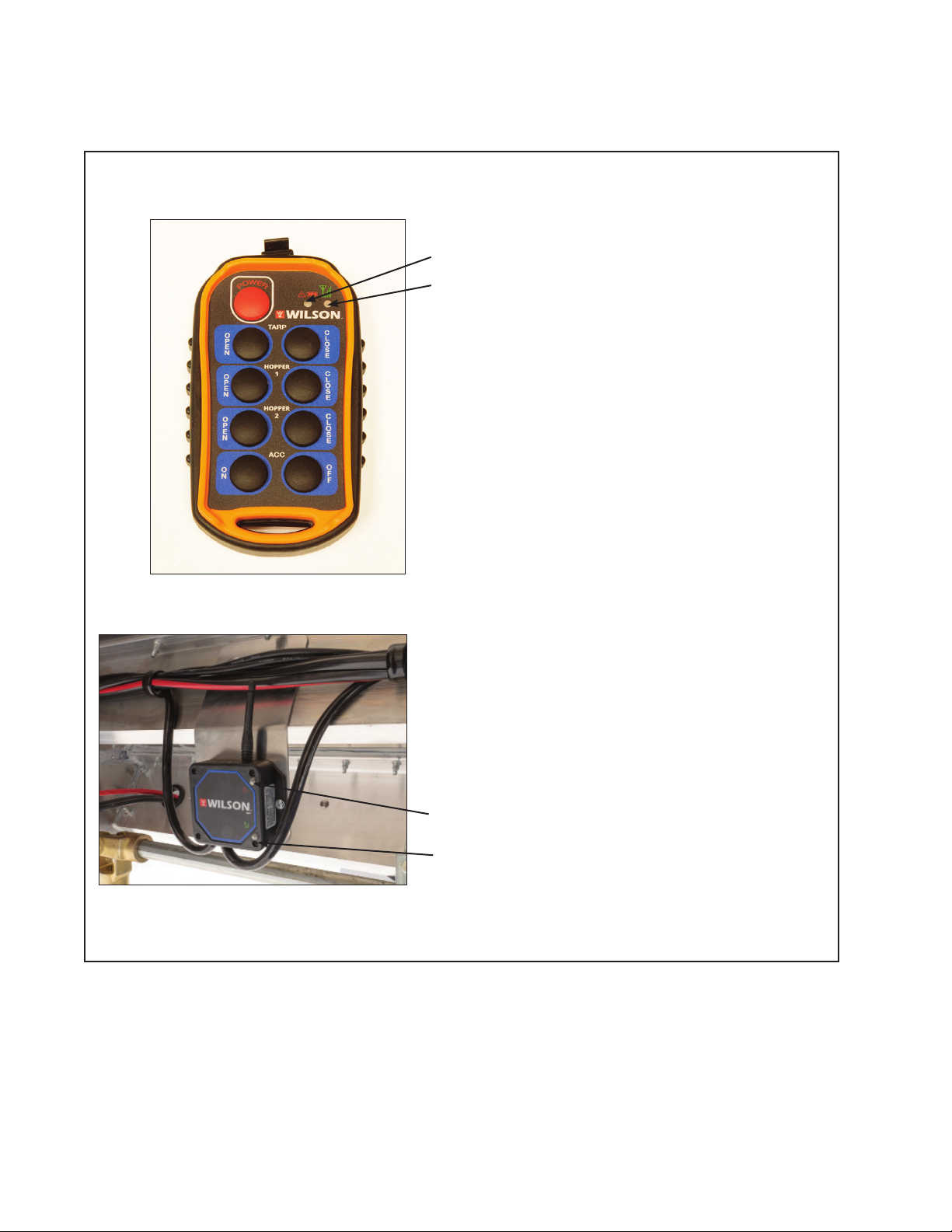

Front of trailer; inside above kingpin

Inspect the inner wall of the front, above the

kingpin. Examine the blue wire power and

white wire ground connections from the

main harness. Inspect the dual conductor

power connections.

Inspect the connections on the tarp module,

dual conductor power system, and control

wire connections. Check the 40 amp fuse

holder for signs of corrosion or debris

buildup and clear drain holes if plugged.

Examine dual conductor cables entering

sidewall of trailer.

REFER TO TROUBLESHOOTING SECTION IF PROBLEMS ARE IDENTIFIED.