• Never hook the winch rope back on itself as this will cause strand damage.

• Do not use the winch as a hoist or for overhead liing. Do not use the winch to li,

support or move personnel.

• Always ensure that the winch rope re-spools onto the drum ghtly evenly, do not

allow cable bunching.

• Never aempt to use a non-sheathed synthec rope with a roller fairlead designed

for wire rope.

• Never approach the winch, hook or cable if someone else is at the controls.

• Always be certain the anchor point can withstand the load and will not slip.

• Protect the wireless remote from any possibility of accidental operaon.

• Never leave the wander lead connected when not in use, protect the wander lead

cable from damage or entrapment in the cable drum.

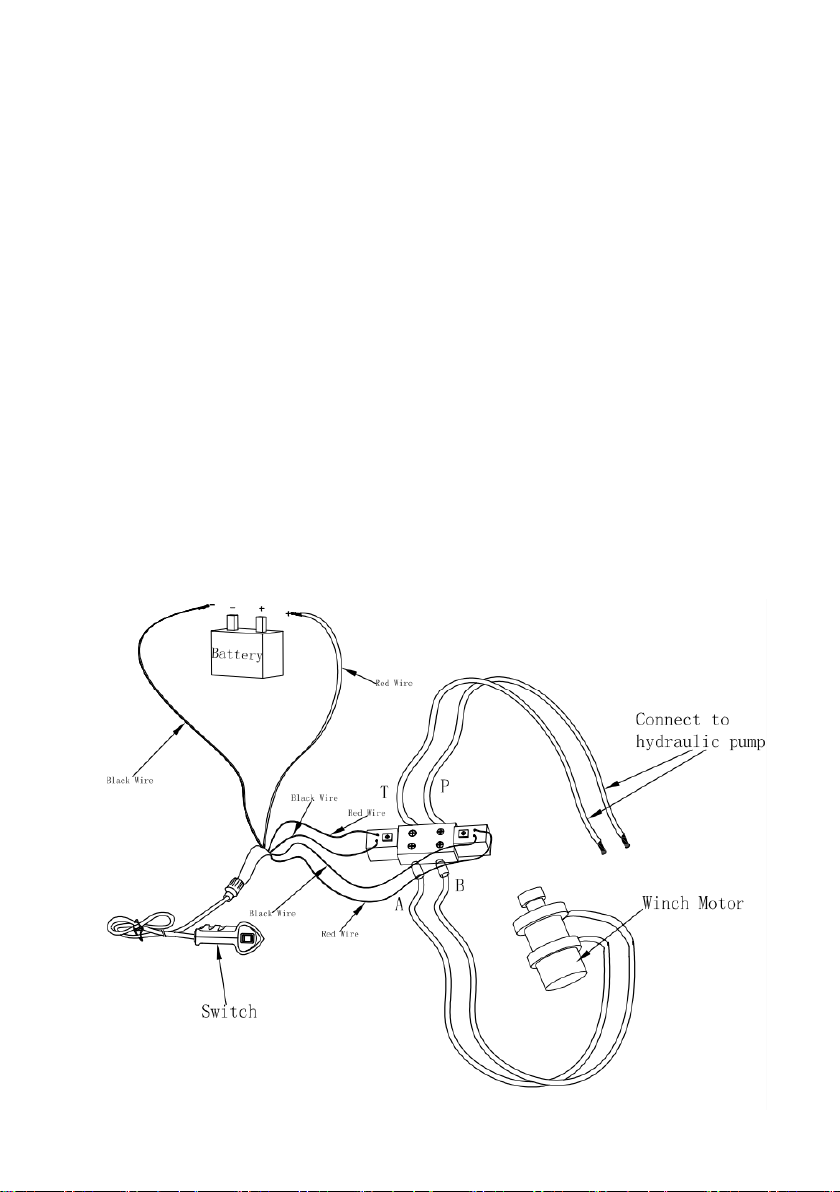

• Always shut down the hydraulic pump before undertaking any maintenance on the

winch.

Physical Installaon

WARNING: Correct installaon of your winch is vital for correct and safe operaon. It is

the responsibility of the installer to ensure that the winch is installed in accordance with

this guide and all relevant regulaons.

When unpacking, make sure that the item is intact and undamaged. If any part is missing

or damaged, please contact your supplier immediately.

• Only install your winch with a genuine WINCHMAX mounng plate or bumper. For

these instrucons, we are describing installaon using a pre-drilled WINCHMAX

mounng plate suitable for atbed installaons.

• The winch must be mounted with the direcon of pull perpendicular to the mounng

bolt xings and the mounng point on the vehicle must be capable of withstanding

the maximum rated pull of the winch.

• Mount the fairlead (rollers if the winch is ed with steel wire rope, or aluminium

hawse if the winch is ed with un-sheathed synthec rope) to the upstand of the

mounng plate using supplied bolts, nuts and washers.

• It must be understood that the fairlead acts as a guide only, it is not designed to

withstand winch loads. It must not be used to change the direcon of the rope any

more than a few degrees in the vercal or horizontal plane.

• If you need to change the direcon of pull to a greater degree, then a suitable snatch

block or pulley must be used.

• Mount the winch to the mounng plate using supplied bolts, square nuts and

washers, ghten the mounng bolts to a torque of 60Nm (45/lb). All mounng

points should be ulised.

• The supplied bolts are the correct length for installaon on a 5-7mm plate. Other

thickness’s may require bolts of a dierent length. The required criteria are that the

bolts are at least 8.8 grade high tensile, the thread length should be suciently long

to fully engage the square nut but must not protrude to the extent that the bolt

contacts the top of the nut housing in the winch frame.