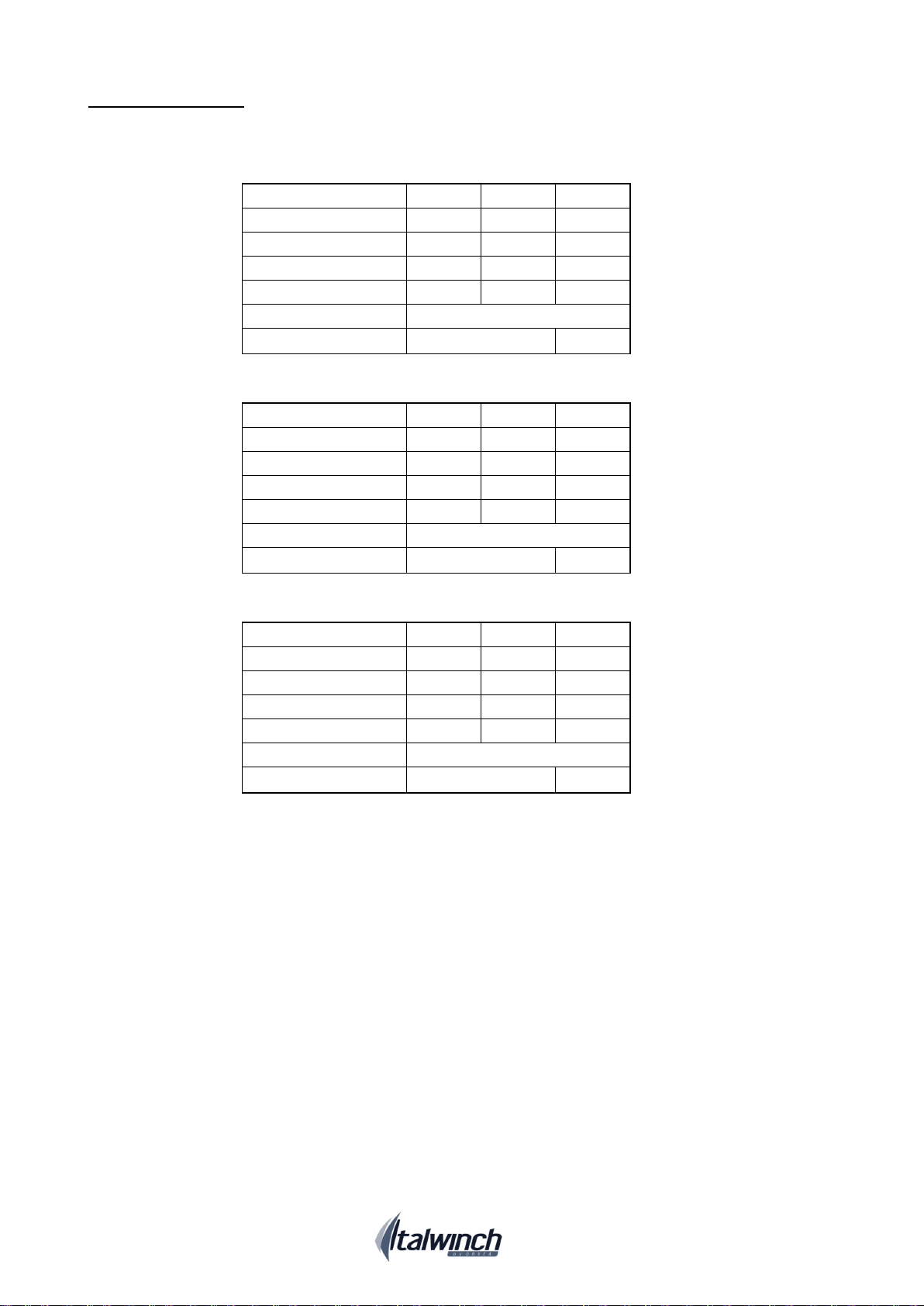

5

Extra care should be exercised when handling polished parts to avoid any damage to polished

surfaces.

Apply an anti-seize compound generously over thread of all screws, before fastening them.

Follow the steps below to disassemble the windlass ready for installation:

1. Unscrew the top cover (2) by turning counterclockwise until it stops. Use the handle supplied.

2. Remove the n.6 M8 capscrews (1) from the top cover (2) and remove it.

3. Unscrew the M8 screw (3) and remove the stop washer (4).

4. Unscrew completely the brass bush (5) until all its thread is out from the main shaft. Two of the M8

screws (1) will be helpful to do this operation.

5. Do not remove the other screws (6)

6. Lift the capstan (7) using the two M12 lifting eyes

7. Lift the chainwheel (9) using the two M12 lifting eyes

8. Remove the key (8).

9. Unscrew the n.10 M12 capscrews (11) securing the drive and mainshaft (13) to the deckplate (12).

10. Carefully slide the drive and mainshaft (13) from the deckplate (12)

To install in the vessel:

1. Cut the hole in the deck as per the deckplate template. All holes must be drilled.

2. Bolt the deckplate in place using an appropriate bedding/sealing compound. Tighten the n.8 M16

capscrews (10) to 150Nm.

3. Fit the drive and mainshaft (13) from below Carefully slide the drive and mainshaft (13) into the

deckplate (12). The lifting eye (M12) can be installed in the end of the shaft to lift from above.

4. Install the n.10 M12 capscrews (10) securing the drive and mainshaft (13) to the deckplate (12).

Tighten to 60Nm.

NB: Confirm the drive and gearbox are clear of the chain and able to be connected to power.

6. Apply grease to the mainshaft (13) and fit the chainwheel (9).

7. Fit band brake assembly (see dedicated section)

8. Grease keyway on main shaft (13) and fit key (8).

9. Slide the capstan (7) onto the main shaft (13).

10. Screw completely the brass bush (5) until all its thread is completely screwed on the main shaft.

Two of the M8 screws (1) will be helpful to do this operation.

11. Fix the stop washer (4) by the M8 screw (3)

12. Fix the top cover (2) by the n.6 M8 capscrews (1). Take care that all the seal are in the right

position and apply grease on all the seal and on the top of shaft.