7REV B 60706-238

DANGER: FIRE/PERSONAL INJURY

All fuel lines must be installed by a qualied fuel supplier.

The fuel source should be as close as possible to the outdoor operating

location. This will reduce the installation cost of fuel runs. Connect the

fuel supply line to the inlet of the fuel demand regulator on the unit

using a locally approved exible fuel line (see table for recommended

line size). The pressure supplied to the demand regulator must be 4 to

6 ounces or 7 to 11 inches w.c. (water column). The primary regulator

at the fuel supply must be capable of delivering the proper volume of

fuel at this pressure.

Have your local fuel supplier install a protected fuel connection at the

outside operating location. They should also install a lockable fuel shut

off valve at the connection point. An approved exible fuel line must be

installed between the engine generator set and the supply line.

DANGER: FIRE/PERSONAL INJURY

The NG fuel supply line must always be shut off when the engine is not

running. Failure to do so may allow fuel to leak at the unit.

INSTALLING THE FUEL LINE

DANGER: PERSONAL INJURY

Units that are intended to be run unattended MUST have an

electric fuel solenoid installed. This solenoid MUST be wired to

AUTOMATICALLY turn off the fuel whenever the engine stops.

Unit location will determine the size of fuel line the is required to supply

the engine with a constant fuel pressure. Refer to the tables below for

fuel line size and recommended tank size. For distances of 100 feet

and over, a two regulator fuel system is recommended. This system

consisting of a primary 10-15# regulator at the tank and a 6 ounce

secondary regulator installed about 10 feet from the generator. You

need to run a 3/4 inch line or larger from the secondary regulator to the

engine-generator set. When a two (2) regulator fuel system is used, a

fuel line size of 3/8 inch is generally adequate for distances up to 300

feet, The line size from the table below applies to the distance from

the second regulator to the demand regulator. A positive fuel shut-off

device must be installed in the fuel line close to the engine-generator

set. This manual shut-off valve is required by code even if the 12 Volt

fuel solenoid kit is installed. This optional 12 Volt DC valve is available

through your local WINCO dealer and can be used to shut off during

normal periods of operation without having to shut off the manual valve.

The fuel line used to connect the supply line to the demand regulator

must be a locally approved exible fuel line. Products used will vary in

different regions depending on availability and local codes. Consult with

your local fuel supplier to ensure complete compliance with ALL codes.

1. Remove the plastic cover plug from the demand regulator.

2. Connect the ex fuel line to the demand regulator or the

optional solenoid.

DANGER: PERSONAL INJURY

Do NOT use galvanized pipe in the fuel line runs. The galvanized

coating will become eroded and ake off, causing possible obstruction

or damage to the regulator or fuel valve. The obstruction could cause

an inoperative engine or an explosive fuel leak.

Size of pipe required for generators operating on NG gas.

Length of fuel line* Fuel line size

Less than 25 feet 3/4/ in black pipe

25-100 Feet 1 in black pipe

Over 100 feet Not recommended**

*Allow an additional 3 feet for each standard elbow. Do not use ‘street

ells’ (restrictive).

**Consult factory for fuel run over 100 feet.

DANGER: FIRE/PERSONAL INJURY

Be careful when sealing gas joints. Excessive sealing compound can

be drawn into the solenoid, regulator, or carburetor causing an engine

malfunction or dangerous fuel leak.

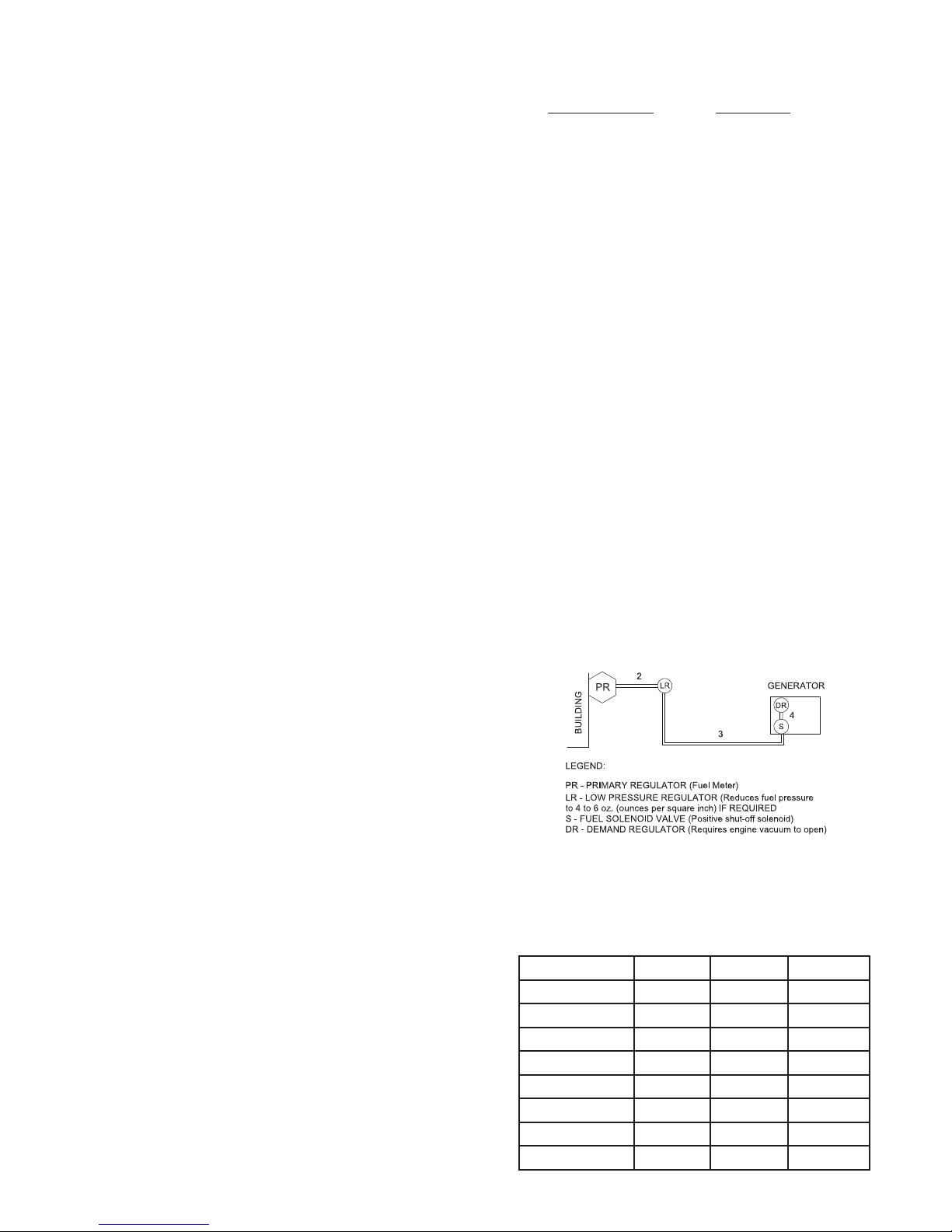

FUEL CONSUMPTION

(Full Load)

Gasoline 1 gal/hr

Natural Gas 160 ft3/hr 163,200 BTU/hr

FUEL PRESSURE

Correct fuel pressure cannot be stressed enough. The most common

cause for inoperative systems is an inadequate or incorrect fuel

pressure. Power and performance of the engine is in direct relation to

the correctness of the fuel system. The following diagram is of a typical

NG installation.

NATURAL GAS

Reference numbers 2 and 3 in the previous diagram are system parts

supplied by the customer. Reference number 4 is the engine-generator

set. The following table is of the fuel pressure reading at each

reference in the system.

Natural Gas Fuel Pressure Table

13240-11 860706-236

Natural Gas

2 3 4

UNIT OFF LINE PSI 7-11 in 7-11 in

4-6 oz 4-6 oz

STARTING LINE PSI 7-11 in 7-11 in

4-6 oz 4-6 oz

NO LOAD LINE PSI 7-11 in 7-11 in

4-6 oz 4-6 oz

FULL LOAD LINE PSI 7-11 in 7-11 in

4-6 oz 4-6 oz

Remember that whichever fuel delivery system or

type of vapor fuel used, the fuel pressure at the

demand regulator installed on the engine generator

must be between 4 and 6 oz. (7-11 inches of water

column). Any lower pressure and the unit will starve

IRUIXHOXQGHUORDG$Q\KLJKHUDQGWKHXQLWZLOOµÀRRG¶

when attempting to start.

LP TANK SIZING

The tank sizes shown below are the smallest recom-

mended tank sizes based on the outside temperature.

Once above this minimum acceptable size, the size of

L.P. tank used will generally depend on how long you

ZDQWWKHXQLWWRUXQZLWKRXWUH¿OOLQJ.HHSLQPLQG

the colder it gets the slower L.P. will vaporize. This

is the reason for the larger tanks at low temperature.

Minimum sizing is not based on running time.

Temp f. 60 deg 30 deg 0 deg -20 deg

150 gal 250 gal 500 gal 1000 gal

CHANGING FUEL TYPES

These engine generator sets are designed to run

on three different fuels; gasoline, natural gas or LP

vapor. They may be easily changed from one fuel to

another.

FROM GASOLINE TO LP/NG

1. With the engine running turn off the gasoline

fuel valve.

2. Run the engine until it runs out of fuel.

3. Remove the plastic insert from the demand

regulator.

,QVWDOODORFDOO\DSSURYHGÀH[LEOHIXHOOLQH

&RQQHFWWKH/31*YDSRUIXHOOLQHWRWKHÀH[-

ible fuel line. You can’t connect the black iron

pipe dir

$OOWKUHHXQLWVKDYHWZRGLIIHUHQWKRVH¿WWLQJV

on the top of the demand regulator. One is for

LP and one is for Natural Gas. Make sure the

KRVHLVDWWDFKHGWRWKHSURSHU¿WWLQJ6HHWKH

picture below.

7. Turn on the vapor fuel.

8. Start the engine.

9 . Apply the load to the generator.

FROM LP/NG TO GASOLINE

1. With the engine running turn off the LP/NG

fuel supply.

2. Run the engine until it runs out of fuel.

5HPRYHWKHÀH[LEOHIXHOOLQHIURPWKHGHPDQG

regulator.

4. Reinstall the plastic insert in the regulator.

5. Check to be sure the gasoline fuel valve is off.

6. Fill the gasoline fuel tank.

7. Turn on the gasoline fuel valve.

8. Start the engine.

If the optional FUEL SOLENOID kit has been in

stalled on the unit all vapor fuel connection will be

made at the 12 volt gas valve.

13240-11 860706-236

Natural Gas

2 3 4

UNIT OFF LINE PSI 7-11 in 7-11 in

4-6 oz 4-6 oz

STARTING LINE PSI 7-11 in 7-11 in

4-6 oz 4-6 oz

NO LOAD LINE PSI 7-11 in 7-11 in

4-6 oz 4-6 oz

FULL LOAD LINE PSI 7-11 in 7-11 in

4-6 oz 4-6 oz

Remember that whichever fuel delivery system or

type of vapor fuel used, the fuel pressure at the

demand regulator installed on the engine generator

must be between 4 and 6 oz. (7-11 inches of water

column). Any lower pressure and the unit will starve

IRUIXHOXQGHUORDG$Q\KLJKHUDQGWKHXQLWZLOOµÀRRG¶

when attempting to start.

LP TANK SIZING

The tank sizes shown below are the smallest recom-

mended tank sizes based on the outside temperature.

Once above this minimum acceptable size, the size of

L.P. tank used will generally depend on how long you

ZDQWWKHXQLWWRUXQZLWKRXWUH¿OOLQJ.HHSLQPLQG

the colder it gets the slower L.P. will vaporize. This

is the reason for the larger tanks at low temperature.

Minimum sizing is not based on running time.

Temp f. 60 deg 30 deg 0 deg -20 deg

150 gal 250 gal 500 gal 1000 gal

CHANGING FUEL TYPES

These engine generator sets are designed to run

on three different fuels; gasoline, natural gas or LP

vapor. They may be easily changed from one fuel to

another.

FROM GASOLINE TO LP/NG

1. With the engine running turn off the gasoline

fuel valve.

2. Run the engine until it runs out of fuel.

3. Remove the plastic insert from the demand

regulator.

,QVWDOODORFDOO\DSSURYHGÀH[LEOHIXHOOLQH

&RQQHFWWKH/31*YDSRUIXHOOLQHWRWKHÀH[-

ible fuel line. You can’t connect the black iron

pipe dir

$OOWKUHHXQLWVKDYHWZRGLIIHUHQWKRVH¿WWLQJV

on the top of the demand regulator. One is for

LP and one is for Natural Gas. Make sure the

KRVHLVDWWDFKHGWRWKHSURSHU¿WWLQJ6HHWKH

picture below.

7. Turn on the vapor fuel.

8. Start the engine.

9 . Apply the load to the generator.

FROM LP/NG TO GASOLINE

1. With the engine running turn off the LP/NG

fuel supply.

2. Run the engine until it runs out of fuel.

5HPRYHWKHÀH[LEOHIXHOOLQHIURPWKHGHPDQG

regulator.

4. Reinstall the plastic insert in the regulator.

5. Check to be sure the gasoline fuel valve is off.

6. Fill the gasoline fuel tank.

7. Turn on the gasoline fuel valve.

8. Start the engine.

If the optional FUEL SOLENOID kit has been in

stalled on the unit all vapor fuel connection will be

made at the 12 volt gas valve.