HOW THIS MACHINE WORKS

86037770 CHARIOT INTERIM 11/18/09

3-3

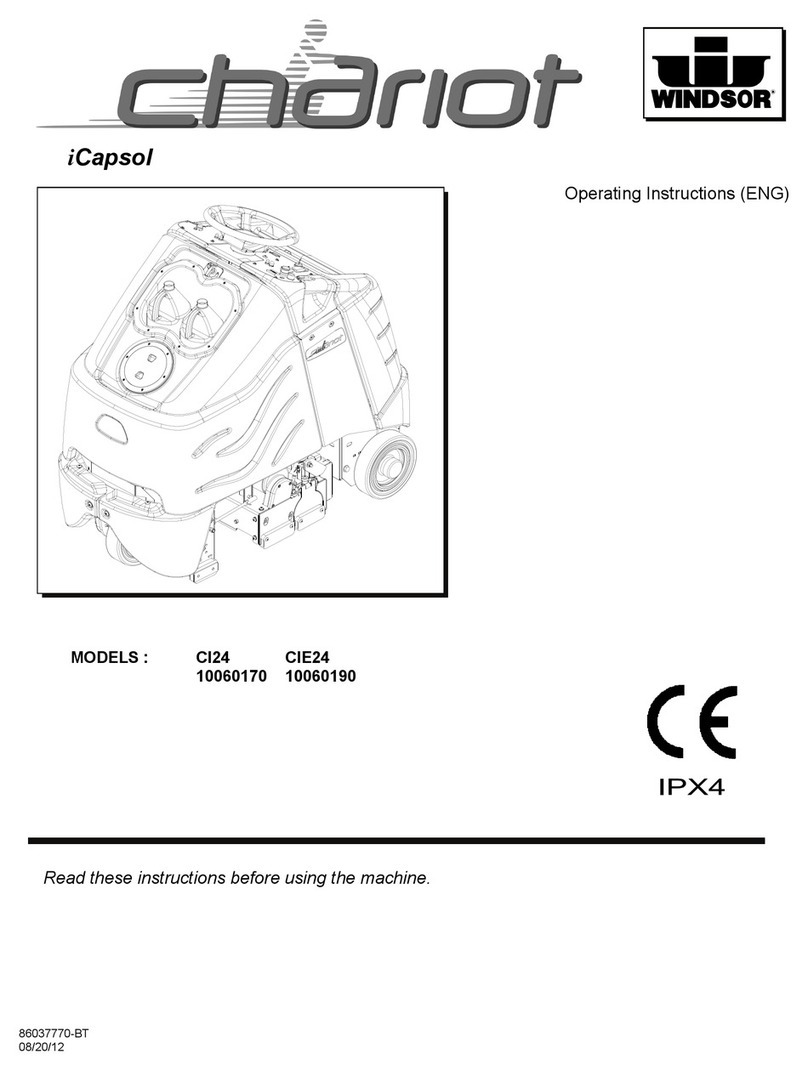

The Chariot iCapsol is a battery powered, self-

propelled Carpet Maintainer intended for commercial

use. The machine is designed to maintain your

carpet using the iCapsol Encapsulating Interim

Carpet Cleaning Process. By using the iCapsol

Carpet Maintainer in conjunction with Windsor Red

Carpet iCapsol Encapsulating Interim Cleaning

(86952260, PRV NO. W450-4) or iCapsol

Encapsulating Interim Cleaning with Carpet

Protection (86952270, PRV NO. W455-4) chemical

solution, you can perform a regular light cleaning

and grooming of your carpet very quickly, and have

the carpet dry and ready for traffic within 30 minutes.

The machine's primary systems are the solution

system, scrub system, and operator control system.

The function of the solution system is to store water

and iCapsol Encapsulating Interim Cleaning

chemical; mix them proportionally and deliver

cleaning solution to the spray jets. The solution

system consist of the solution tank, strainer, pump,

selector valve, injector, shut-off valve, spray jets and

controls. The solution tank stores water until it is

delivered through the strainer and pump to the

injector and spray jets. The strainer protects the

pump from debris. The selector valve allows the

operator to flush clean water (from the solution tank)

through the injector system to keep it clean. The

injector siphons iCapsol Encapsulating Interim

Cleaning at an 8oz/gallon rate (1:16 ratio).

The shut-off valve automatically prevents solution

flow unless the scrub brushes are turned on and the

machine is being propelled forward. The solution

pump switch controls the cleaning solution flow to

the spray jets.

The function of the scrub system is to scrub the

carpet, mix the iCapsol Encapsulating Interim

Cleaning solution with the soil so as to encapsulate

it, and lift and groom the carpet pile. The scrub

system consist of two cylindrical brushes, motors,

hopper, lift actuator, and controls. The brushes

scrub the carpet as the motors drive the brushes.

The counter-rotating action of the brushes picks up

debris and throws it into a removable hopper. The

actuator switch controls the lift actuator and brush

motors to lower the deck and turn the motors on, or

raise the deck and turn the motors off. The brush

motors will automatically turn off when the throttle

pedal is in neutral.

The function of the operator control system is to

control the direction and speed of the machine. The

directional control system consists of the direction

control switch, throttle pedal, speed control switch,

drive reset switch, emergency stop/brake switch,

steering wheel, propel controller, drive wheel and

operator presence pedal,prior to Serial Number

(10*). The directional control switch signals forward

or reverse direction. The controller interprets signals

from the throttle pedal to command the drive wheel

to propel or slow the machine. The drive reset switch

is to make sure the operator is on platform before

machine will propel. The steering wheel points the

drive wheel in the direction desired by the operator.

The parking brake automatically engages when the

operator steps off the platform. The emergency

stop/brake can be used to hold the machine on

slopes.

*See Serial Number page.