Your cellar is provided with an automatic defrosting system.

If for any reason manual defrosting is required, press and hold down button 10

for a few seconds and the refrigeration will be interrupted for ten minutes: the

pilot light (9) will flash.

Once the 10 minute interval has passed, the cellar will resume its normal operation

at the previously programmed temperatures.

STORAGE

The plasticized steel or wooden shelves inside the cellar are very sturdy and can

be arranged in the cellar to take various size bottles

To position the shelves at different heights, follow these steps:

Take out the shelf, remove the side guides (rails) by unscrewing the 2 fastening

screws, replace the rails in the position required (and make sure that the screws

are in tight) and then place the shelf back into the unit.

As an alternative to static shelves (except for CI 140 CF Model) sliding shelves

can be fitted - these should be requested on ordering

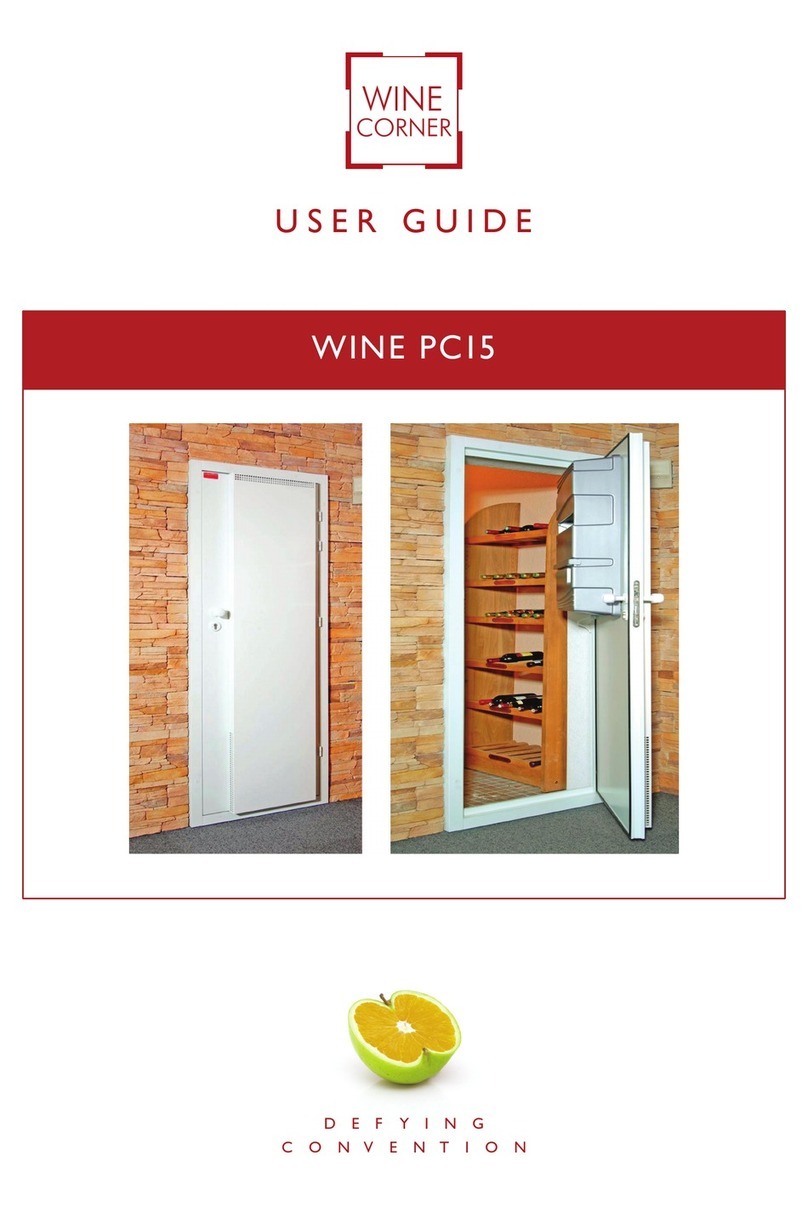

REVERSING THE DOOR

The door can be EITHER LEFT OR RIGHT HINGED according to requirements.

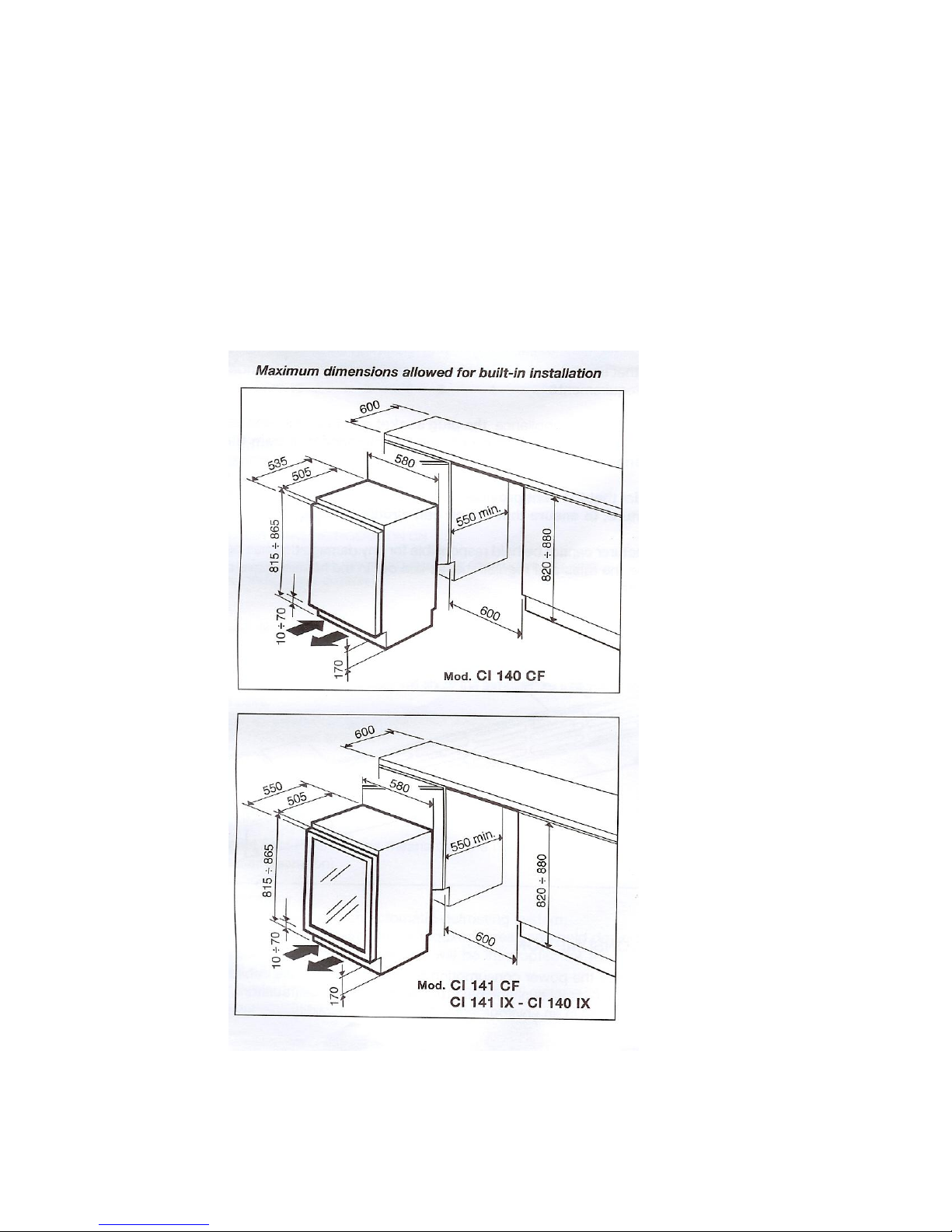

CI 140 CF Model with panelled door

To change which way the door is hinged, follow these instructions:

-To remove the door, remove the screws (pictures 1-2) at the top and bottom

-Remove the screws from the upper and lower hinge;

-To reverse the door: rotate the hinges by 180°, remember that when you are

changing the position of the hinges on the door that the top hinge becomes

the bottom and vice versa.

-Secure the hinges in the holes provided on the opposite side;

-Secure the lock plates of the door panel into the opposite side; Secure the door to the hinges.