1.

CABINET LAYOUT Cont.

C binet volume (m³)

Polystyrene fo m

= 0.044 W/m°C

(mm)

Extruded polystyrene

= 0.030 W/m°C

(mm)

Polyureth ne fo m

= 0.025 W/m°C

(mm)

2

25 20 20

3

30 25 20

4

40 30 25

5

45 30 25

6

50 35 30

8

60 45 40

10 80 55 45

12 90 65 55

15 110 80 70

1.2.1

WALLS, CEILING AND FLOOR INSULATION

Choice of insul tion p nels

The ma ufacturers recomme d the followi g i sulatio pa els:

•

Si gle layer i sulatio pa els

•

“Complex” i sulatio : i sulatio is covered with a claddi g material (plaster, mi eral, etc.),

•

Sa dwich: i sulatio is covered o each side with a woode pa el or plaster board.

Important:

Coveri gs protect the i sulatio from impact a d guara tees its lo gevity. Avoid usi g

mi eral- fibre i sulatio pa els (glass wool, rock wool, etc.) as they ca absorb moisture a d lose their

i sulatio qualities.

Floor insul tion

The cellar floor must be able to support the racks a d the wi e stored. I sulatio must therefore be chose with a

sufficie t compressive resista ce.

Reduce the risk of damage from pu ctures (i.e. from wi e racks or shelvi g legs) by usi g the followi g:

•

“Complex” i sulatio pa els, coveri g their top side with a sufficie tly resista t pa el.

•

Coveri g the i sulatio with a chipboard pa el (thick ess arou d 15 mm), or a y other appropriate coveri g

(e.g.

screed a d slab).

1.2.2

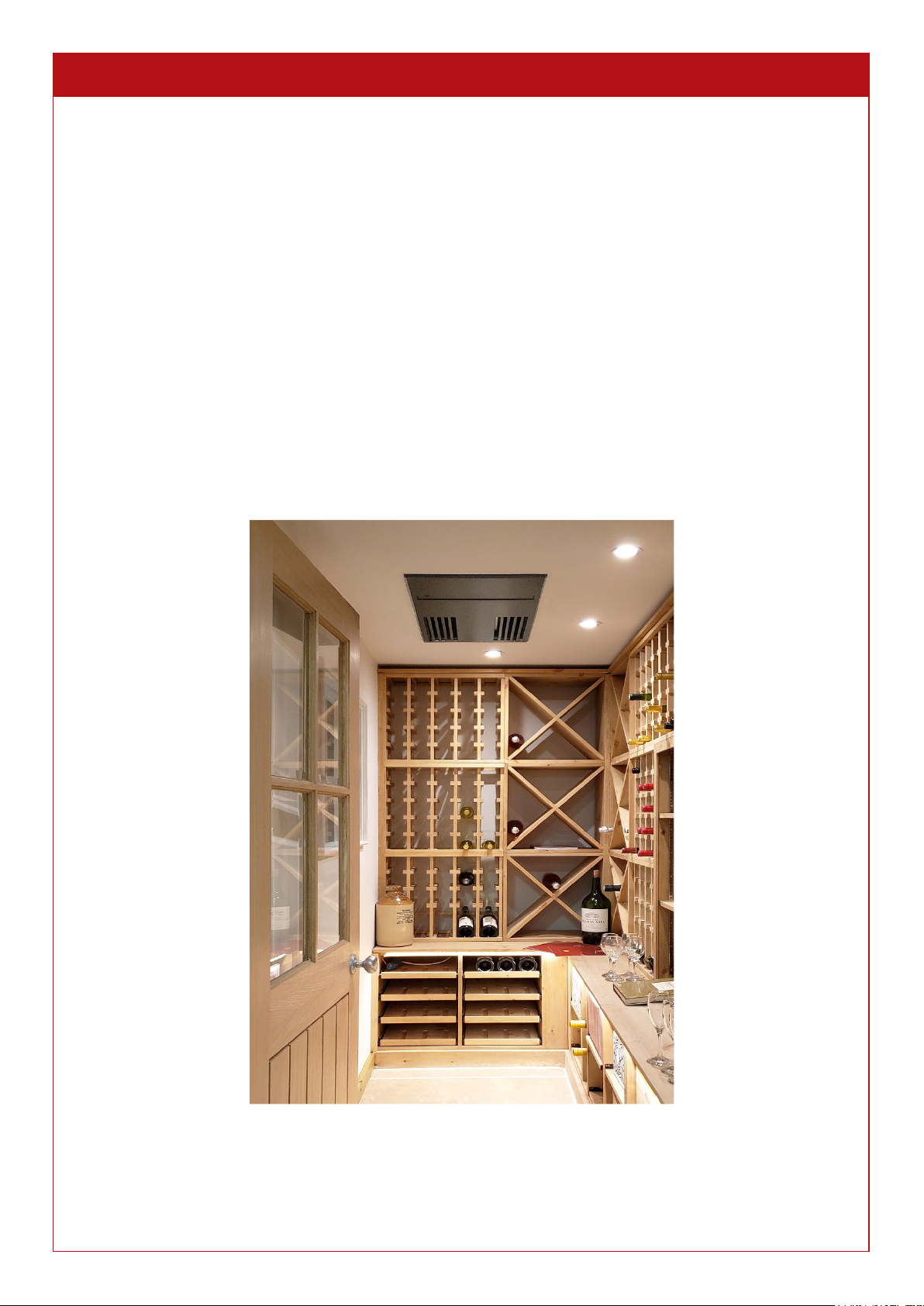

DOORS

These form part of the i sulatio co ti uity. There are two possible solutio s:

•

Glazed doors: double-glazi g or eve triple-glazi g must be used with a good UG coefficie t (max. 1.2 W/…….)

•

If solid doors are used, they should be i sulated i the same way as the other walls.

Page 6

DID YOU KNOW?

Some i sulati g materials are damaged by rode ts (mice, rats, etc.). You should therefore check that the cellar

walls have o gaps or cracks through which rode ts ca reach the i sulatio . If ecessary, cover the

i sulatio o the i side of the cellar with a protective li er.

Polyuretha e as a i sulati g material, due to its chemical compositio , will ot be damaged by rode ts.