9

4. USE

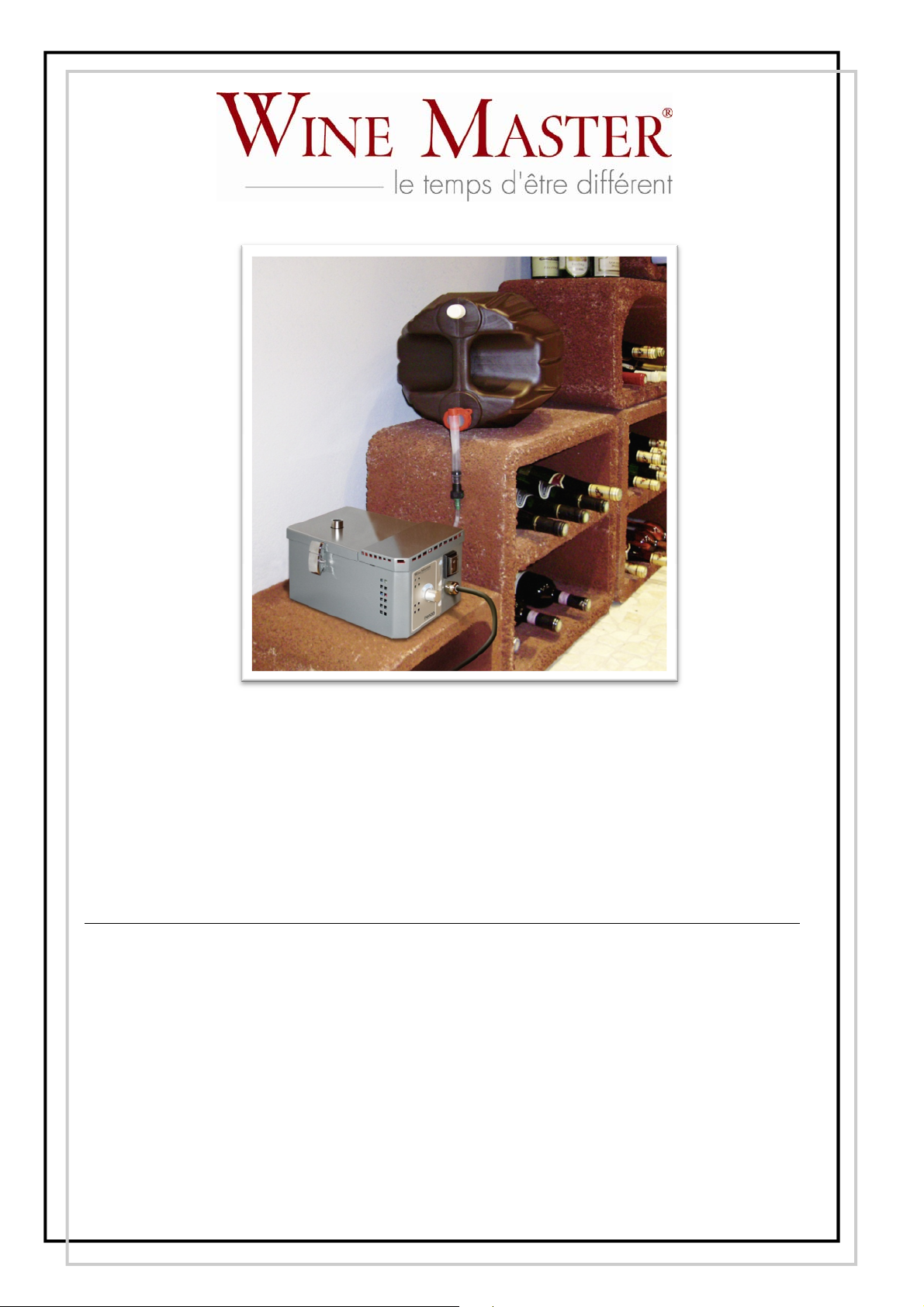

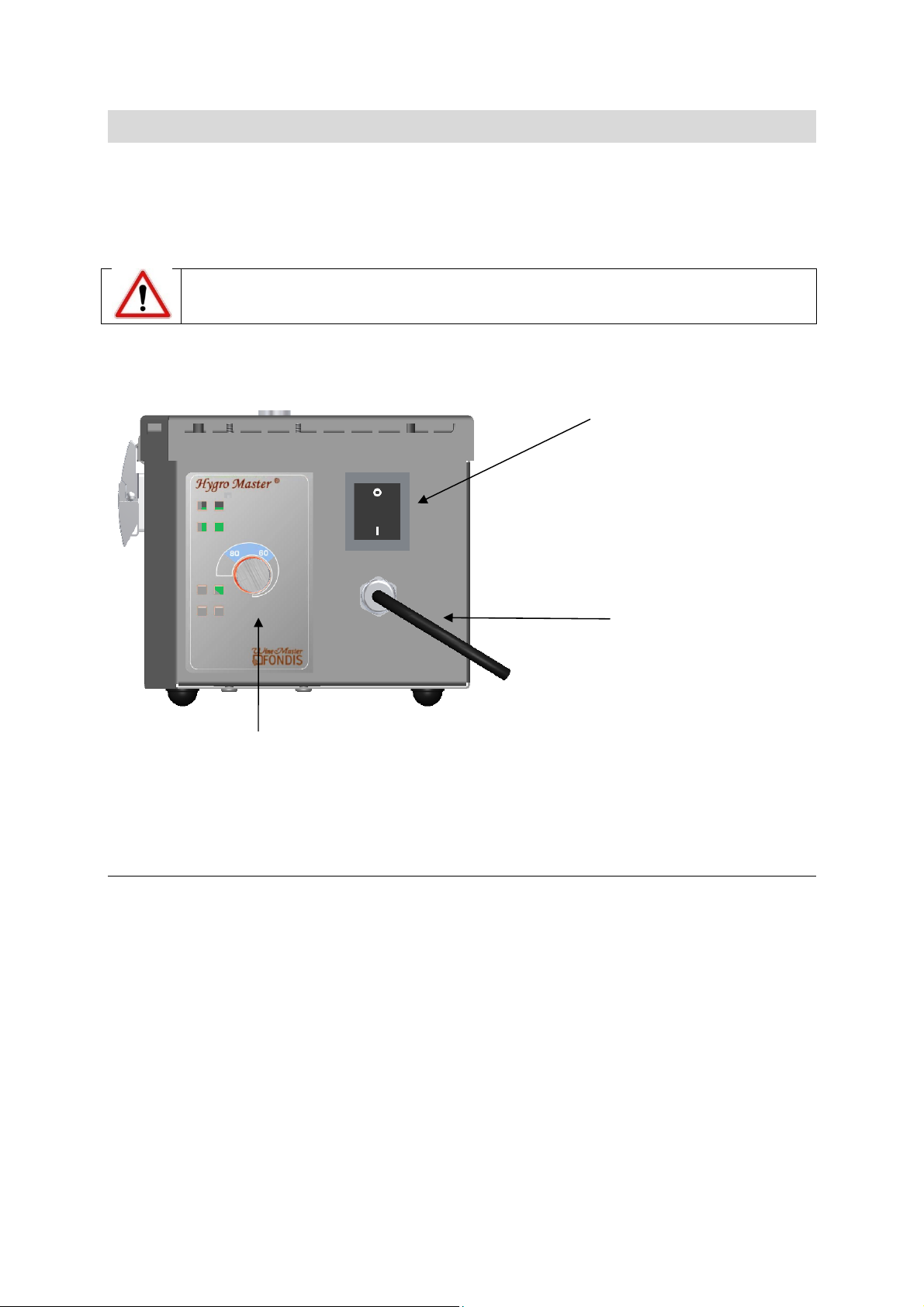

-In winter switch HYGROMASTER® to the humidification position. (I)

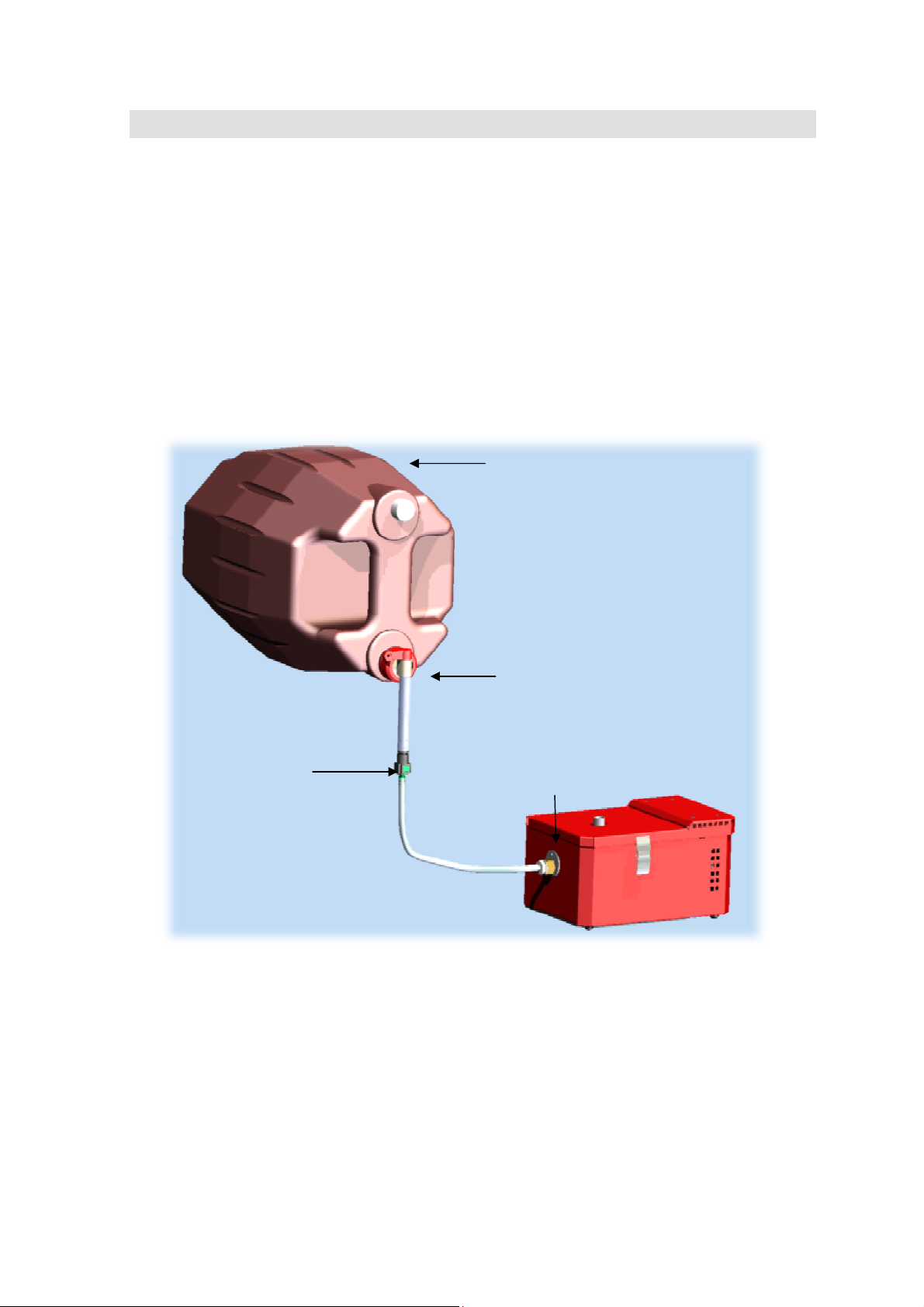

-Check and fill the water tank regularly.

-In summer, stop humidification to prevent the disruption of refrigeration and the

excessive production of condensate

5. MAINTENANCE

Attention with the risks of burns in particular on sheets around the vat

In case of questions, do not hesitate to contact your retailer or the Fondis Customer

6. PRESERVATION OF WINE

Its preservation and ageing require an environment that satisfies certain conditions.

More than temperature itself, it is the stability of the cellar temperature which is

important for the good preservation of wine.

The ideal temperature of a wine cellar is approximately 12 degrees. Above twenty-five

degrees, young white wines run the risk of a secondary fermentation. On the contrary,

for certain red wines, their ageing will be accelerated..

The central heating pipes, the proximity of a boiler, parasite air entries, refrigerators,

freezers, are the worst enemies of wine.

A good cellar must neither be too dry, nor too humid. The action of dry air is insidious: it

dries out the corks, causes significant evaporation of the wine through the corks and

makes the bottle leak. An excess of moisture will increase the development of moulds on

barrels and corks. The ideal level of hygrometry is between 60 % and 80%, it can rise to

90 % without damage to the wine. The cellar must be closed, without vibration. The

racks or shelves are insulated from any source of vibration, they rest on the ground

rather than fixed on a wall, more sensitive to vibrations. The ageing of wine occurs away

from light. The cellar must thus be dark and the duration of lighting limited. If these

conditions are satisfied, wine will keep for a long time. The cellar will provide good

maturation and optimum ageing. Wine is not as fragile as it is often believed, it must

primarily be protected from its main enemies: abrupt temperature variations, light.