Operating Instructions

Container Heaters (0-90°C) WOCP, WODPX, WODPK

Winkler AG ▪Englerstrasse 24 ▪69126 Heidelberg ▪Germany ▪Phone: +49-6221-3646-0 ▪sales@winkler.org ▪www.winkler.org

Page 3of 18

Disassembly and storage

Switch off the heater and allow it to cool down completely. Disconnect it from the power supply before disassembly.

Then check it for damage and contamination and the connection cable for defects.

Do not use solvents or abrasive cleaners to clean the heater and never immerse it in liquids. To clean, gently wipe the

surfaces and controls with a damp cloth. Keep the heater away from sharp edges and pointed objects.

If you find defects or damage of any kind, do not put the heater into operation again. Do not attempt to

repair a damaged one yourself.

When the heater is not in use, it should be stored in a dry and clean environment in its original packaging. To do this,

gently roll it loosely along the pockets without squeezing or bending it.

Disclaimer

All information - including illustrations and graphical representations - corresponds to our current state of knowledge

and has been written to the best of our knowledge. Specifications are subject to change without notice. In addition, we

reserve the right to make changes without notice to the design, materials or workmanship in the interest of technical

progress.

In these operating instructions you will find all the important information on mounting and commission-

ing. In addition, you will find important information for your safety as well as for help in case of problems.

The user of this product must decide on his own responsibility about its suitability for the intended use.

Contents

Safety Introductions………………………………………………………………………………………………………………………………………………… 2

1Introduction ....................................................................................................................................................... 4

2Applicable standards.......................................................................................................................................... 4

3Intended operation ............................................................................................................................................ 5

4Scope of delivery................................................................................................................................................ 5

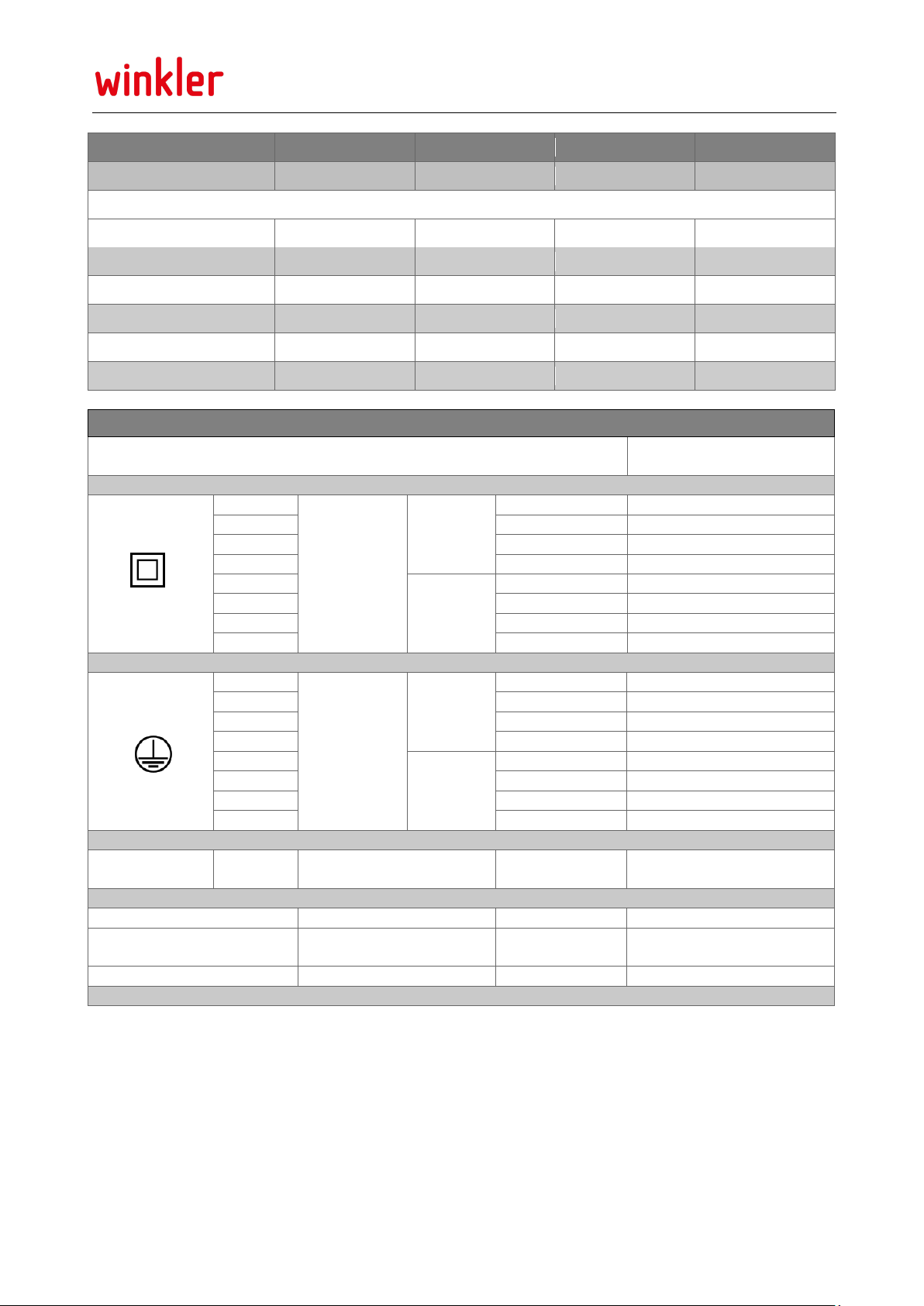

5Drum heater....................................................................................................................................................... 5

5.1 Intended use and application............................................................................................................................5

5.2 Technical data ...................................................................................................................................................5

5.3 Structure ........................................................................................................................................................... 6

5.4 Assemblage ....................................................................................................................................................... 7

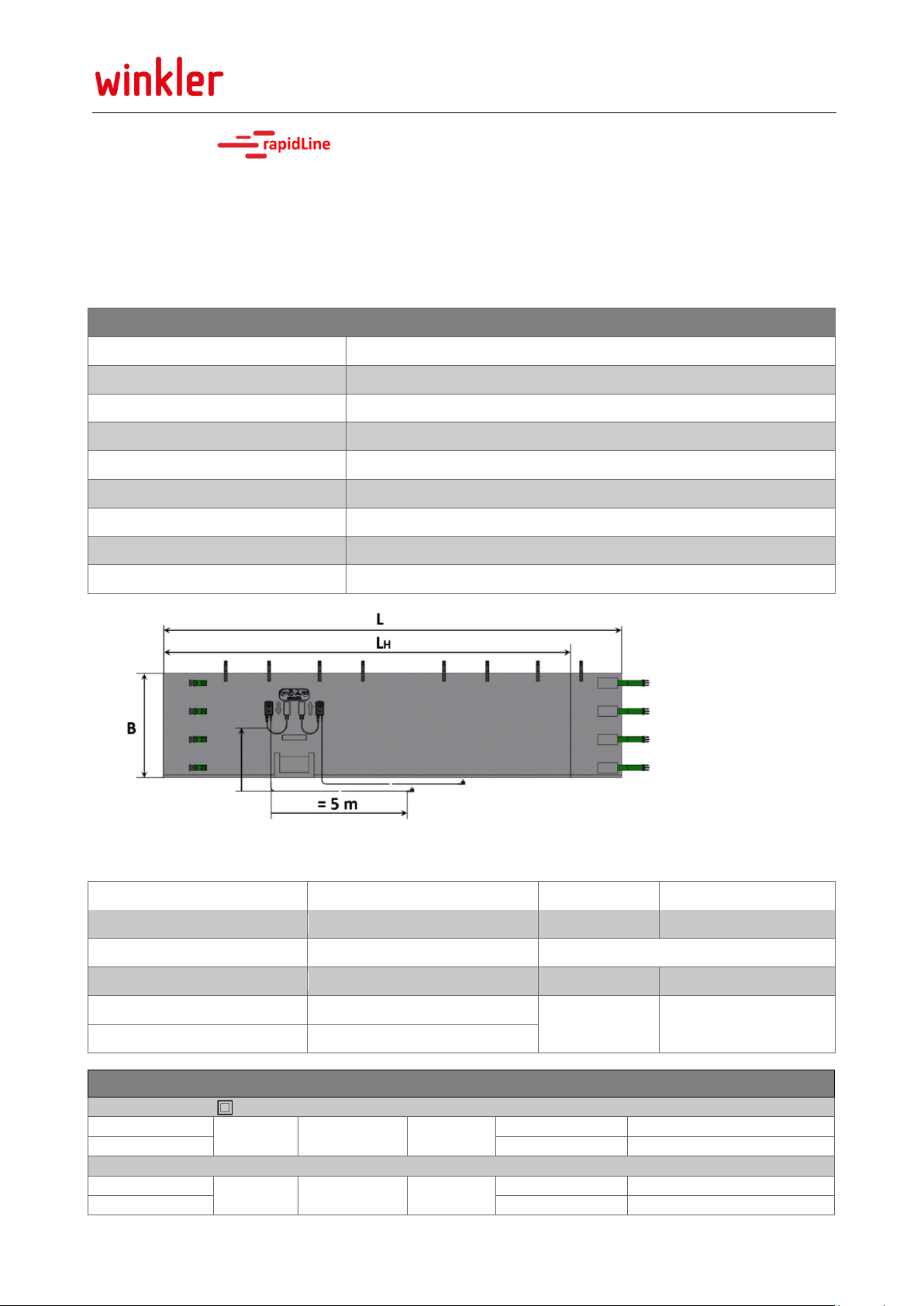

6IBC-Heater.......................................................................................................................................................... 8

6.1 Intended use and application............................................................................................................................8

6.2 Technical Data...................................................................................................................................................8

6.3 Structure ........................................................................................................................................................... 9

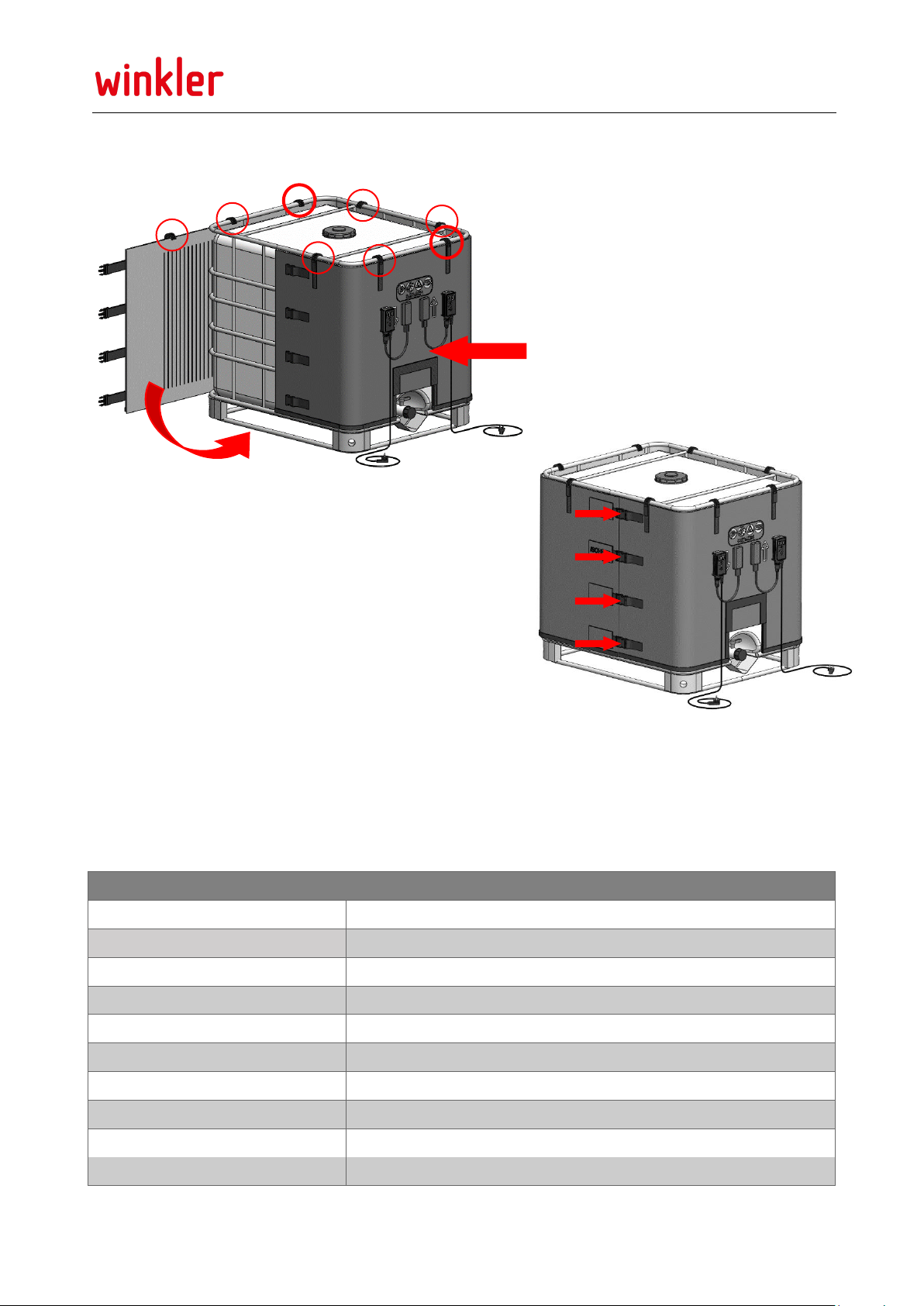

6.4 Assemblage ....................................................................................................................................................... 9

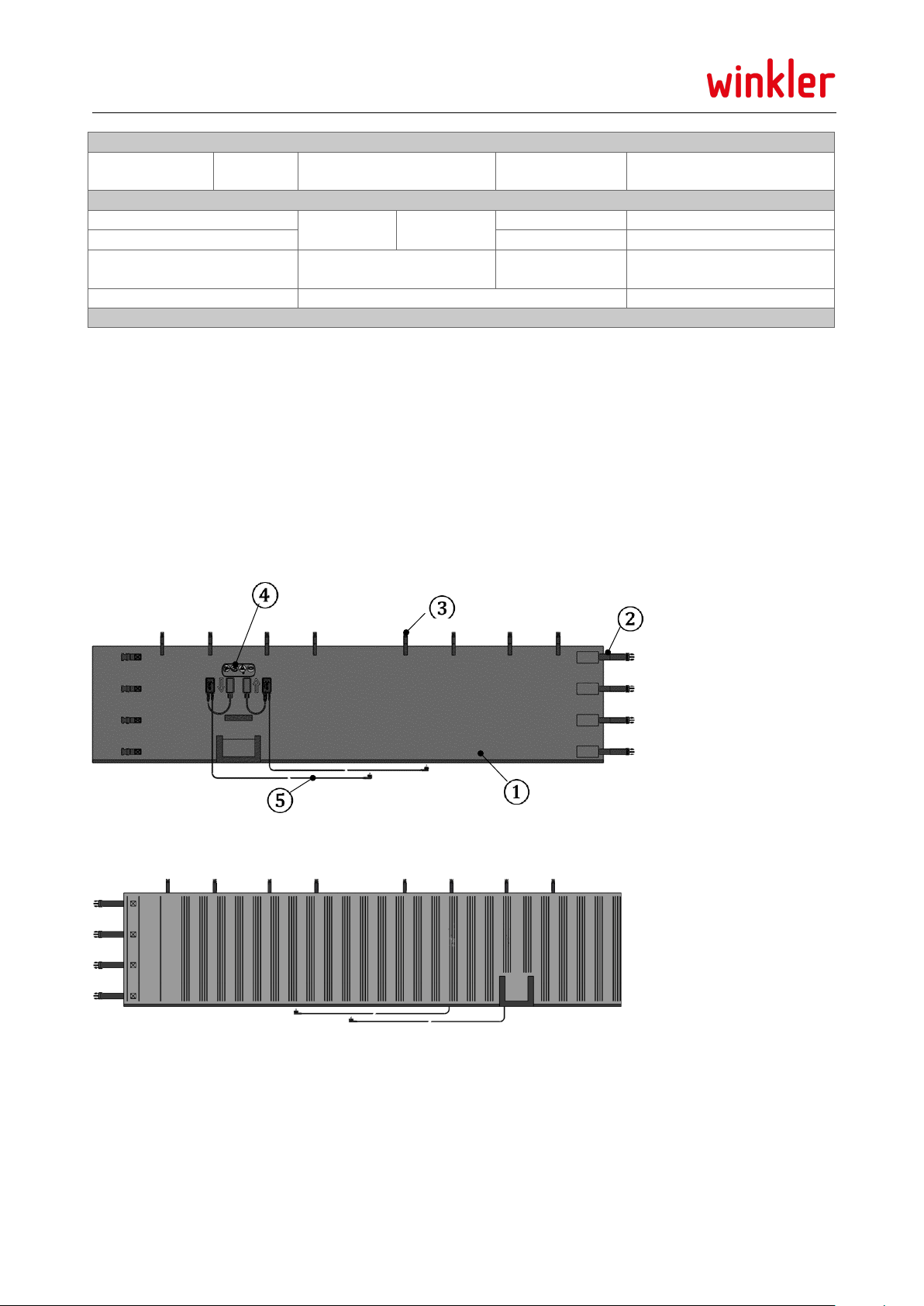

7Canister Heater WODPK....................................................................................................................................10

7.1 Intended use and application..........................................................................................................................10

7.2 Technical Data.................................................................................................................................................10

7.3 Aufbau.............................................................................................................................................................11

7.4 Assemblage ..................................................................................................................................................... 12

8Commissioning..................................................................................................................................................13

9Troubleshooting and problem solving ...............................................................................................................13