D-011-0152 3

Table of Contents

General Information............................................................................................................................... 5

Overview............................................................................................................................................ 5

How to Use This Manual.................................................................................................................... 6

Block Diagrams.................................................................................................................................. 7

Symbols on the Product or Manual Labeling ..................................................................................... 8

Monitoring Screens............................................................................................................................ 9

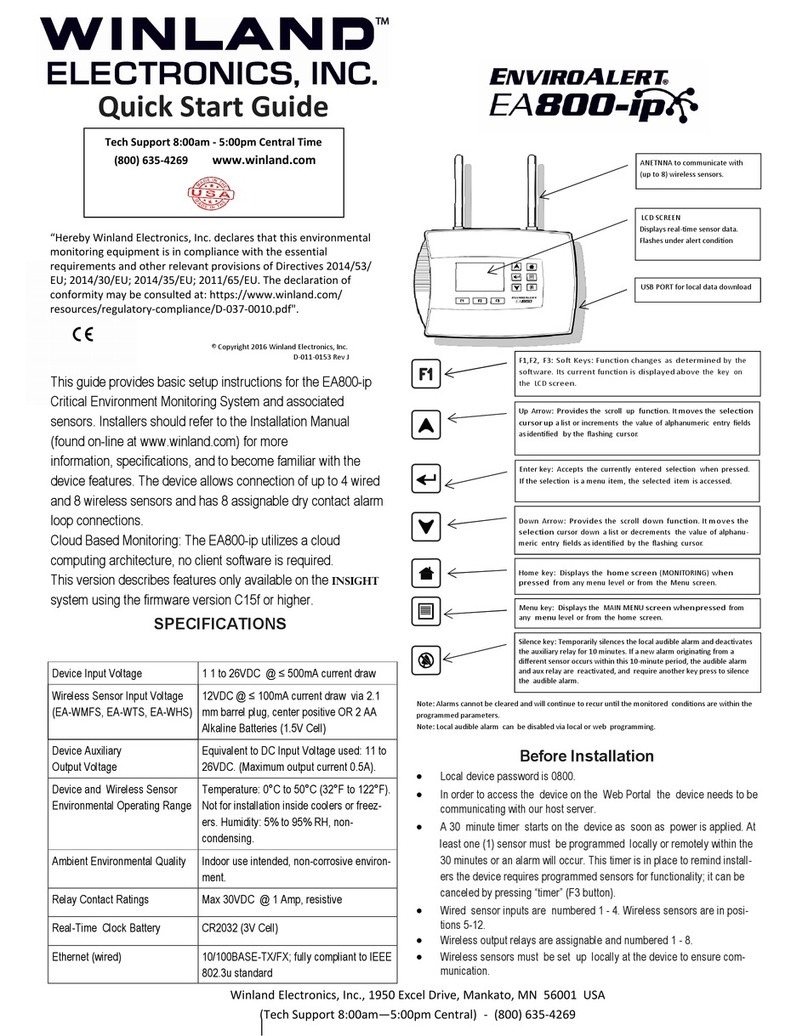

Keys................................................................................................................................................. 10

Console Connections....................................................................................................................... 11

Access Control and Passwords ....................................................................................................... 13

System Configuration Parameters................................................................................................... 13

Sensors............................................................................................................................................ 15

Temperature Sensors ................................................................................................................ 15

Humidity Sensors....................................................................................................................... 16

4-20mA Sensors ........................................................................................................................ 16

Theory of Operation ....................................................................................................... 16

Power Supply / Sensor Voltage Selection...................................................................... 17

Water Sensors ........................................................................................................................... 18

Multi-Function Sensors .............................................................................................................. 18

Dry Contact Sensors.................................................................................................................. 18

Sensor Parameter Descriptions ................................................................................................. 19

Relay Operation............................................................................................................................... 21

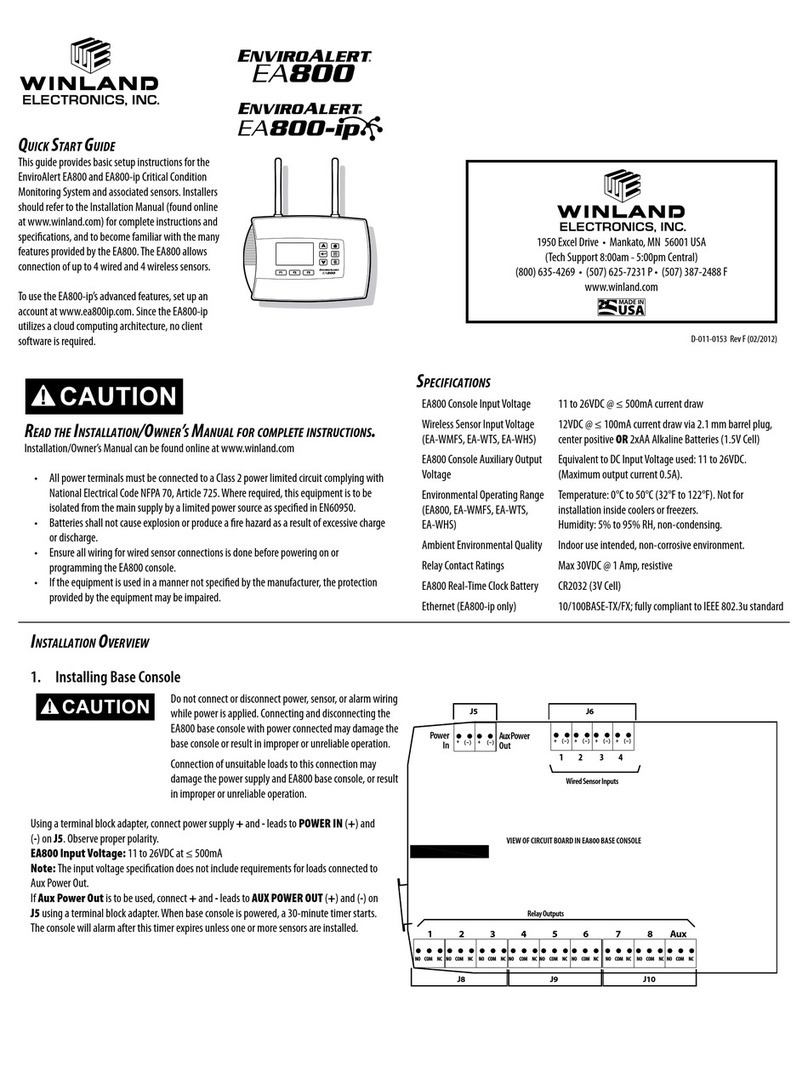

Installation............................................................................................................................................ 22

Tools and Supplies Required........................................................................................................... 22

Power Requirements ....................................................................................................................... 22

Mounting the EA800-ip Rear Plate .................................................................................................22

Install the Wired Sensors................................................................................................................. 23

EA800-ip Console Power Connections............................................................................................ 23

Install the Wireless Sensors............................................................................................................. 23

Connecting Wired Sensors .............................................................................................................. 25

Programming ................................................................................................................................... 27

Accessing the MAIN MENU for Programming ........................................................................... 28

Configuring System Parameter Settings.................................................................................... 28

Adding Wireless Sensors................................................................................................................. 29

Verify Wireless Signal Strength ................................................................................................. 31

Adding Wired Sensors ..................................................................................................................... 32

Adding a Wired Sensor .............................................................................................................. 32

Adding a 4-20mA Sensor........................................................................................................... 33

Configuring the Relays..................................................................................................................... 34

Operation.............................................................................................................................................. 35

Monitoring Environmental Conditions .............................................................................................. 35

Viewing Sensor Settings.................................................................................................................. 36

Viewing Active Alarms ..................................................................................................................... 36

Viewing the Alarm Log..................................................................................................................... 37

Viewing the Event Log ..................................................................................................................... 38

Viewing the Sensor Log................................................................................................................... 39

Viewing Firmware Information ......................................................................................................... 39

Viewing RF Information.................................................................................................................... 40