4Winterhalter Gastronom GmbH

Postfach 1152

D-88070 Meckenbeuren

89000825

10/98 sch

NOTE

The measuring cup supplied with our detergent

containers holds approx. 200g of powder. One

heaped dessertspoonful of powder is equivalent to

approx. 20g. To avoid staining the tank floor, it is

advisable to dissolve the detergent in hot water

before adding it or to pour it onto the plastic

surface strainers.

NOTE

Only use detergent and rinse aid products

which are suitable for commercial dishwashers.

Observe the safety information printed on the

packaging.

We recommend the use of our Winterhalter

Gastronom detergent.

NOTE

If the machine is equipped with an automatic

detergent dosing device (optional extra), there is

no need to add detergent manually.

See the corresponding instruction manual on how

to use this device.

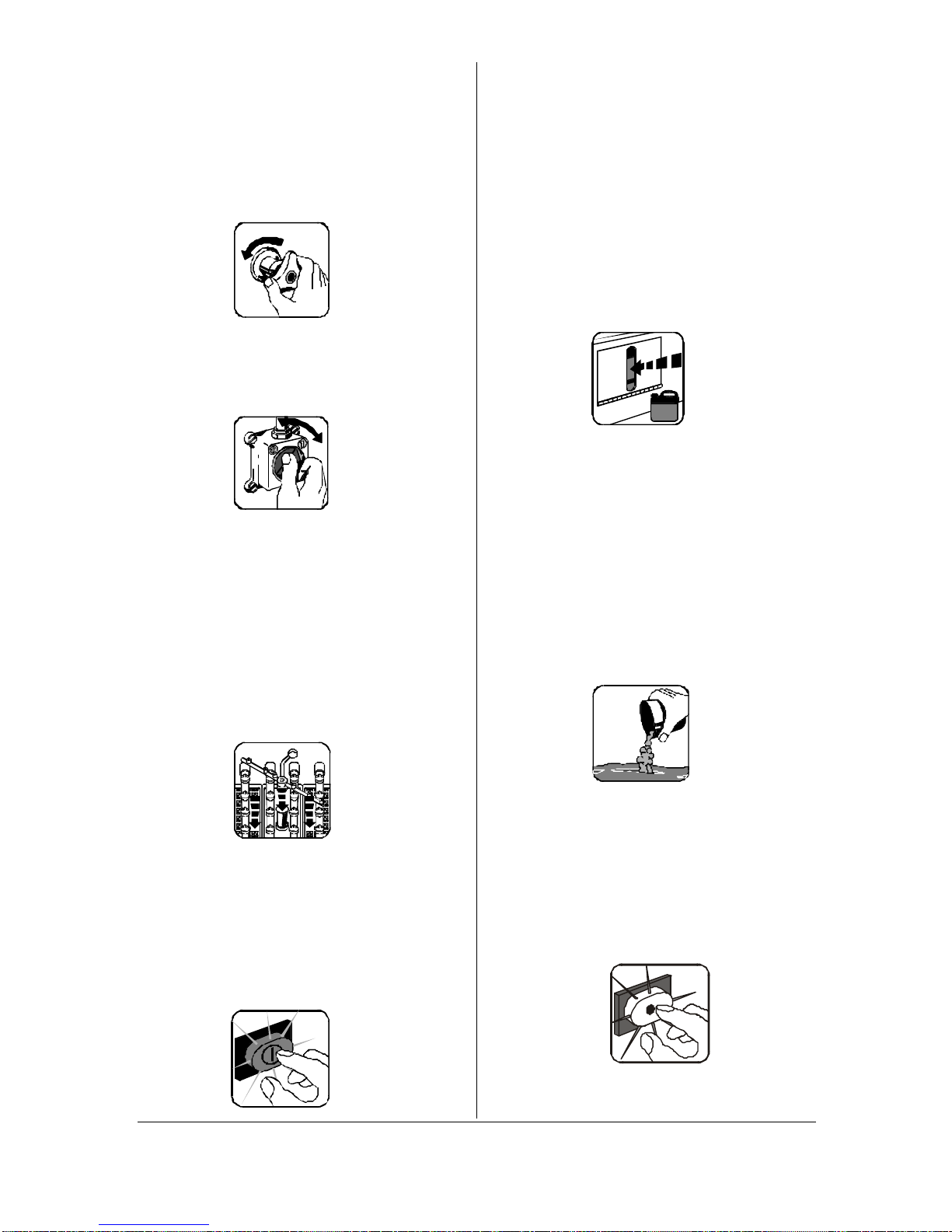

6. Topping up the regenerating salt

(GS 14E, GS 15E)

In models GS 14E and GS 15E with built-in water

softeners (SoftMatik), the "REG" indicator (7)

lights up when the salt level in the container is low.

In this case, fill the salt container with special

regenerating salt for water softeners.

The salt container must only be filled

with regenerating salt! Any other

chemicals, e.g. detergent or rinse aid,

will inevitably result in damage to the machine.

The salt should be added in fine-grain form (max.

5-7 mm grain size): salt tablets are not suitable.

We recommend the use of our Winterhalter

SoftMatik regenerating salt.

Procedure:

•Unscrew the cap of the salt container.

•Fill the container with one bag (500g) of

Winterhalter Softmatik regerating salt

using the supplied funnel.

•Remove salt remnants from the screw thread

and sealing surface of the salt container.

•Screw the cap of the salt container back on

again and tighten it by hand.

•Activate Programme 1 by pressing key (3).

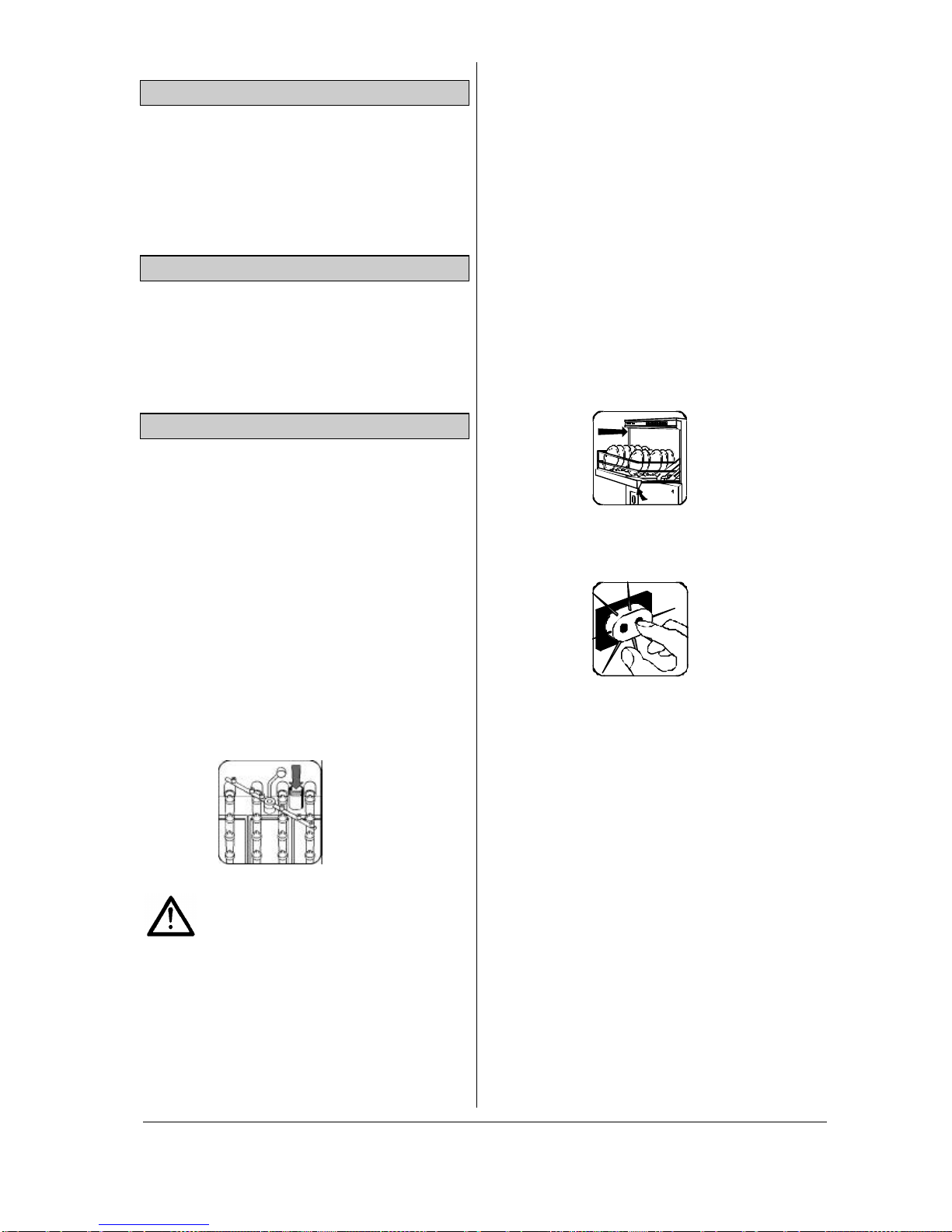

7. Wash cycle

Arrange the soiled kitchenware correctly in the

rack, then push the rack into the machine and

close the door.

Select the right programme for the relevant degree

of soiling and press the button to start.

For lightly soiled items, you should select the

”Programme 1” button (3). Programme duration:

GS 14 approx. 150s = 24 racks/h

GS 14E approx. 150s = 24 racks/h

GS 15 approx. 75s = 48 racks/h

GS 15E approx. 120s = 30 racks/h

For heavily soiled items, select the ”Programme 2"

button (4). Programme duration:

GS 14 approx. 300s = 12 racks/h

GS 14E approx. 300s = 12 racks/h

GS 15 approx. 150s = 24 racks/h

GS 15E approx. 180s = 20 racks/h

Sequence of operations

•Circulation of detergent solution: intensive

cleaning from above and below.

•Freshwater rinse with water heated to 85°C

(containing rinse aid).