Assembly instructions | 89014664; 2022-04 | 1

1 Introduction

1.1 About these operating instructions

These instructions contain information for the installation and connection of a dosing unit of a competitor. Dosing units of a competitor

are dosing devices that do not come from Winterhalter Gastronom GmbH. To be able to work safely with the dosing device, the safety

and operating instructions provided must be observed. Compliance with the valid national accident prevention regulations and general

safety provisions must be ensured.

1.2 Copyright

The instructions are protected for the manufacturer by copyright.

The instructions contain guidelines and drawings or parts of drawings of a technical nature, which may not be reproduced, distributed,

used for the purposes of competitors without authorisation or shared with others, either in whole or in part.

The operator of the warewasher is permitted to make copies, in whole or part, expressly for internal application relating to the operation

of the dishwasher. The manufacturer is entitled to claim damages for any infringements. Further rights reserved.

© 2022 by Winterhalter Gastronom GmbH

1.3 Proper use

– The dosing device is used for the automatic dosing of detergent or liquid rinse aid in commercial warewashers.

– The dosing device is a technical device for commercial use only.

– Train operating personnel in handling the dosing device and point out safety notes.

1.4 Improper use

– Children must not be allowed to play with the dosing device.

– Do not install dosing devices inside or on cover elements of Winterhalter warewashers.

– Winterhalter Gastronom GmbH assumes no liability for any damage caused by improper use of the dosing device.

To avoid damaging the warewasher and to achieve a good wash result:

– Do not use acidic detergents.

– Do not use foaming products (e.g. manual washing-up liquid) for pre-treating the wash items.

2 Safety notes

– The additional devices may be connected to the electrical mains supply only by a specialist company registered within the elec-

trical trade and approved by the energy supplier.

– Work on the electrical system, installation and maintenance work as well as repairs may be carried out only by qualified specialists.

– When working on the electrical system, doing installation and maintenance work as well as repairs, observe the electrical engineer-

ing safety rules to avoid electrical accidents:

– Disconnect all power supply points.

– Secure the machine against being switched on again.

– Check that there is no voltage present.

– Earth and short circuit.

– Cover or cordon off neighbouring parts that are live.

– Touching live components can lead to death by electric shock. In the event of a defect or damage to an electrical component /

cable or its insulation, switch off the power supply immediately and arrange for its repair by a specialist.

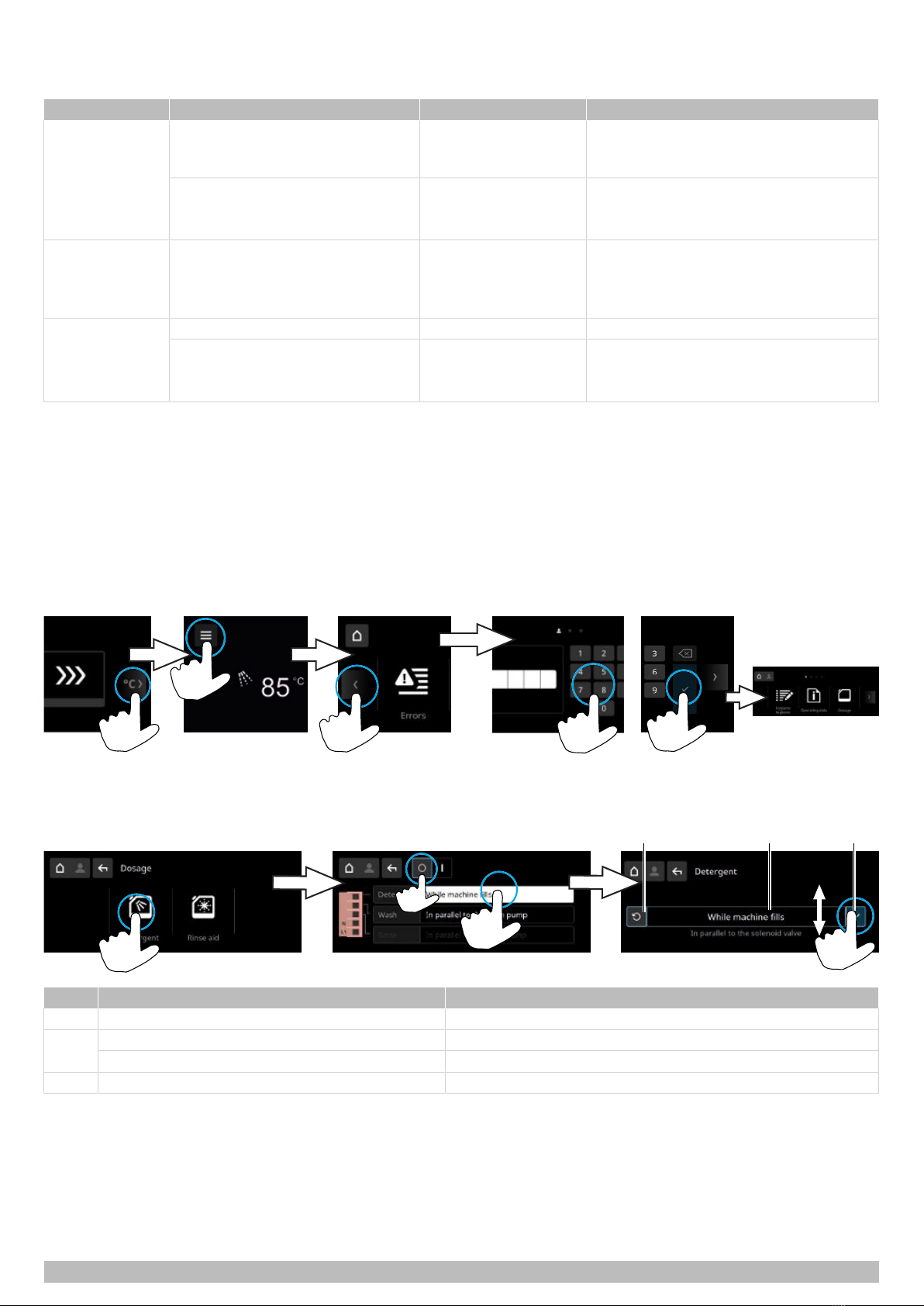

Connection of external dosing devices to CTR Series V01

Assembly instructions