1143500 Replacing SmartPAC PRO HMI Board

Instruction Sheet September 2018 1143500

Replacing SmartPAC PRO HMI Board Rev. A Page 5

Wintriss Controls Group 978-268-2700 toll free 800-586-8324

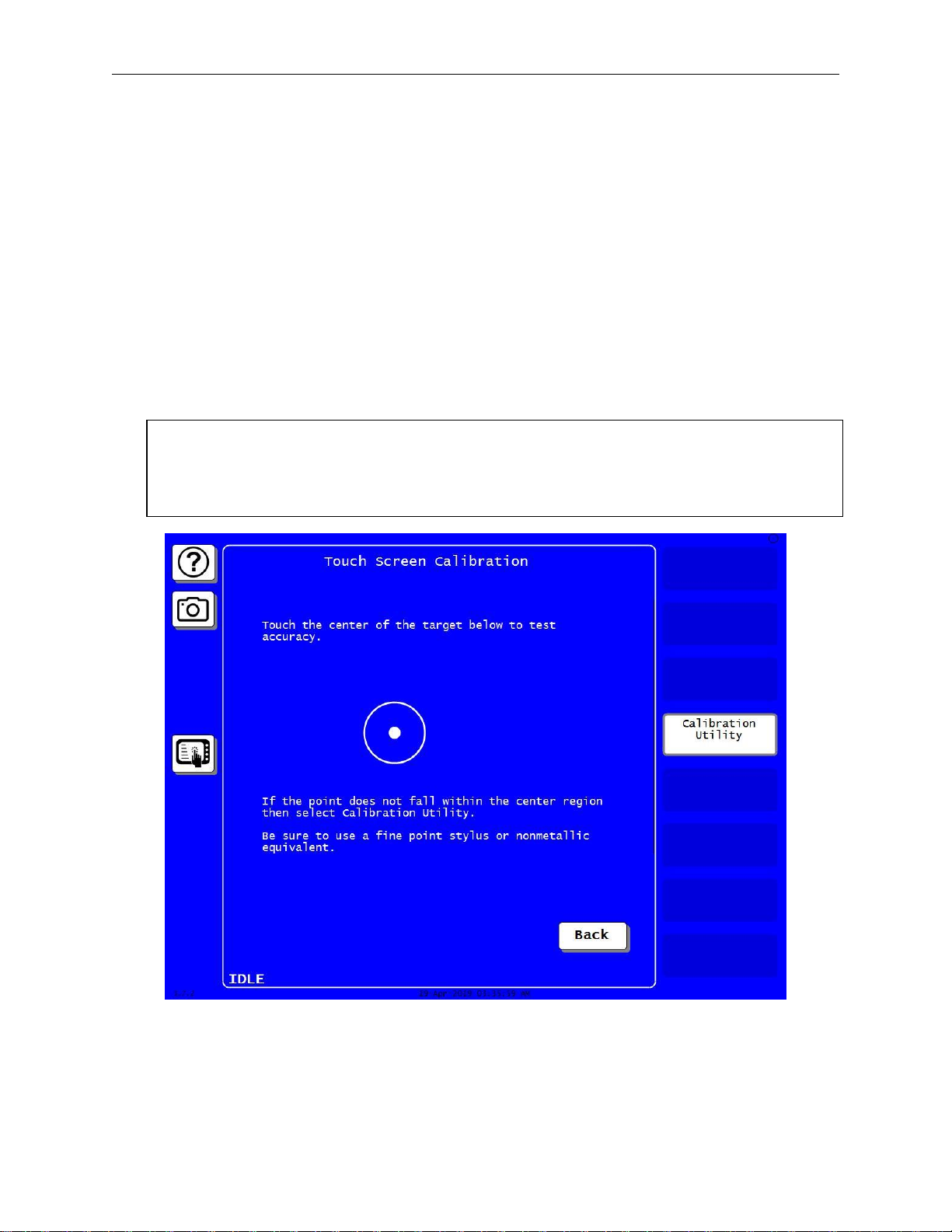

18. Follow the directions on the “Touch Screen Calibration menu. Note: Do not touch any

portion of the screen with any part of your hand etc., or the test will not work correctly.

19. Using a fine point stylus, touch the center of the target. If the small pink dot falls within the

center of the target the screen is calibrated (There is also an “On target” message). Press

the Back button a couple of times and then the Exit button to return to the main program

menu.

20. If you are unable to center the pink dot in the target, the screen needs to be calibrated.

Press the Calibration Utility button to calibrate. A yellow message box will appear with

instructions. Have your stylus and USB mouse plugged in and ready. Press the Yes button

to continue with the calibration. When the calibration is complete the SmartPAC PRO will

reboot on its own.

Board Exchange Only

21. Place the malfunctioning HMI board in the anti-static bag in which you received the

replacement board.

22. Place the anti-static bag with the old board in the box in which you received the

replacement board and ship it back to Wintriss Controls, using the shipping label with the

Return Authorization (RA) number. Contact Wintriss Tech Support if you have additional

questions 800-586-8324.

NOTICE

Before setting up and running a job, it is a good idea to test a few SmartPAC PRO modes and

menus to make sure the touch screen is properly calibrated and the unit is operating normally.

If you have swapped your SD card (Step 12, page 3) from the old board to the replacement

board it is a good idea to go into the Tool Manager (Program Mode) and verify that all your

tools have been restored. If you experience any problems, Contact Wintriss Tech Support

800-586-8324

NOTICE

If your SmartPAC PRO is networked you will need to reprogram its network settings back in.

To do this, go to the MAIN INITIALIZATION MENU, select SETUP NETWORK and then select

CHANGE NETWORK SETTINGS.