SERVICE MANUAL & ICA

WIPLINE 3730 & 3900 FLOATS

P/N 1002551 Revision K Page 3

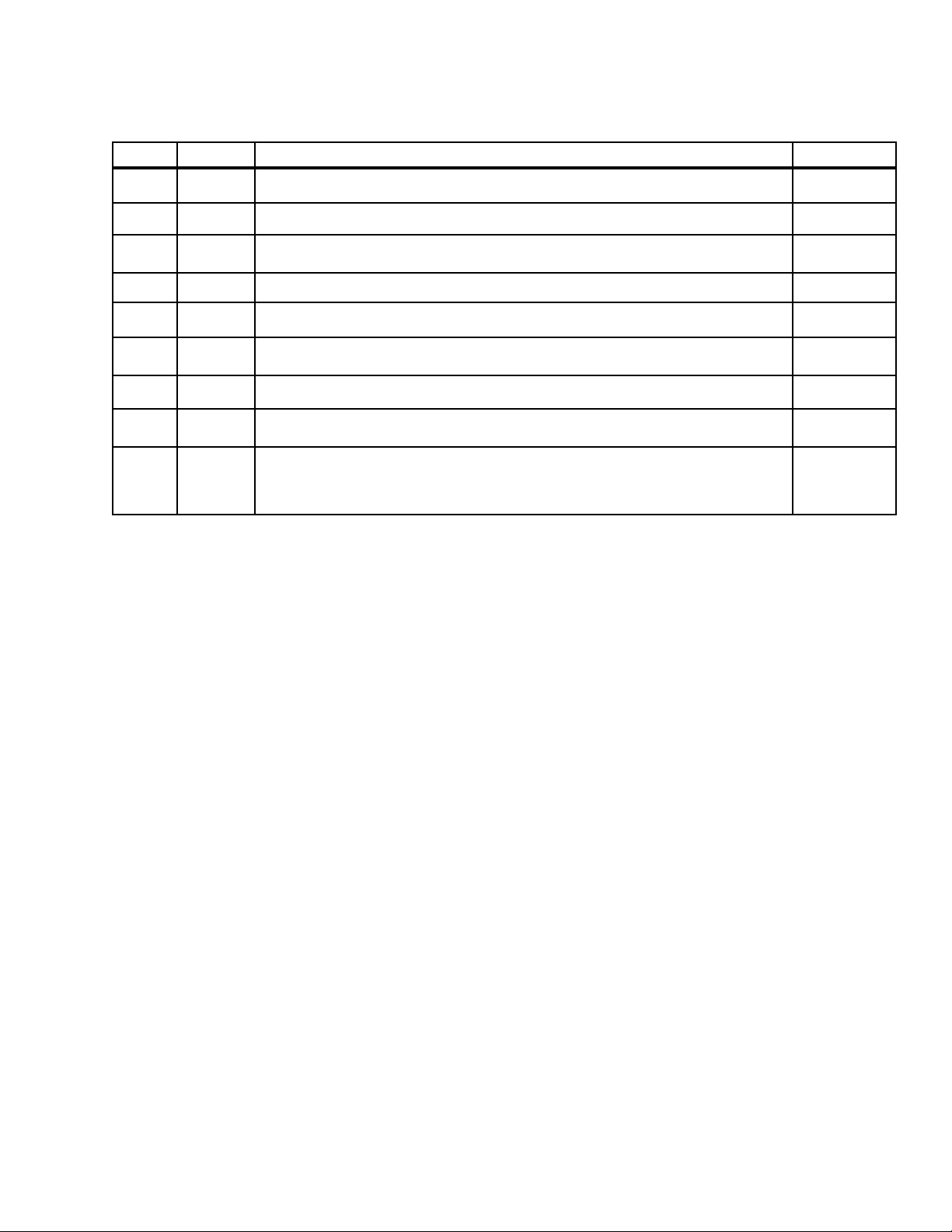

LOG OF REVISIONS

Rev Pages Description Date

A 12 Added an inspection time limit and tolerances for the Nose Block Track wear. 4/1/2006

B 4, 14-16 Updated TOC, added new inspection checklist. 2/23/2007

C&D TOC, 6-8,

16-18 Table of contents updates, expanded corrosion prevention, added steps to insp. checklist. 10/31/2008

E All Reformat of entire document, add green grease as approved grease. 4/16/2013

F 20-21 Added Shear Torque Chart, PR 1440 C Sealant and Tef-Gel, removed Warranty Claim Form. 5/26/2015

G5, 11,

20-21

Added Dow Corning DC4, Corrosion X, and Mobil Aviation Grease SHC 100 to approved

product list. Modied torque limits section. 12/4/2015

H 8 Added reference for Structural Repair Manual part number 1008274 in introduction. 5/1/2019

J11, 13, 21,

23-25

Added information about corrosion limits. Added note about STA-Lube. Added STA-Lube to

Brake Caliper Grease. Removed inspection column from Maintenance Checklist. 8/3/2020

K All

Reformatted manual in new software. Removed Comet Industries GP-730A. Removed content

in Chapter 8 and replaced with note about SRM. Removed Figures 6 through 14 as content is

found in SRM. Added note about nose box sealant and Service Letter 224. Added sections 2.6

through 2.9

2/3/2021

View most current revision of this ICA at www.wipaire.com.