SERVICE MANUAL & ICA

WIPLINE 7000 FLOATS

Page 6 Revision P P/N 1004646

LIST OF FIGURES

FIGURE 1-1 FRONT VIEW ........................................................................................................................9

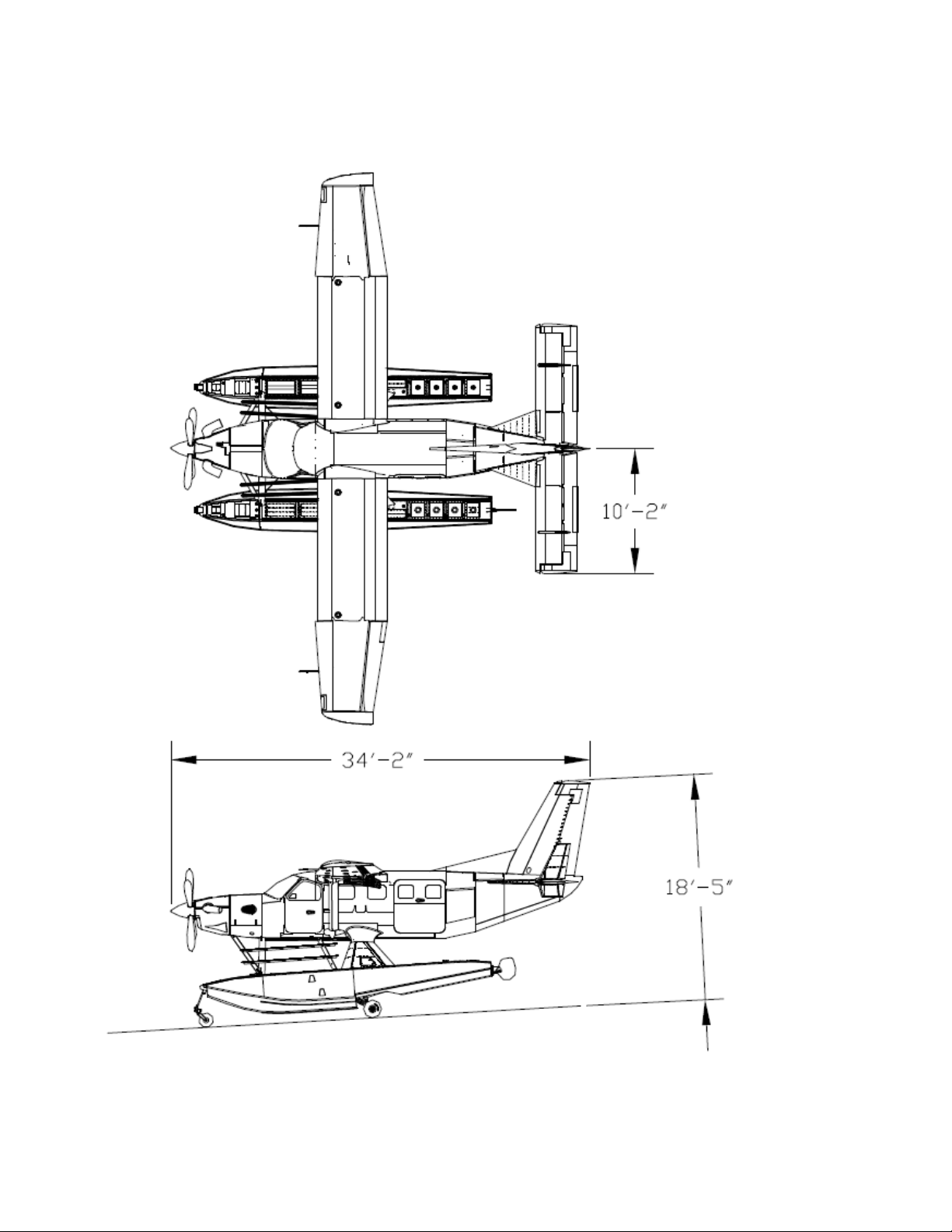

FIGURE 1-2 TOP & SIDE VIEWS............................................................................................................10

FIGURE 1-3 FLOAT TERMINOLOGY .....................................................................................................11

FIGURE 1-4 MAINTENANCE ACCESS POINTS...................................................................................12

FIGURE 1-5 HYDRAULIC FLUID LEVEL PLACARD ............................................................................14

FIGURE 1-6 FLUID TYPES AND QUANTITIES .....................................................................................14

FIGURE 1-7: JACK CRADLE RECOMMENDED MODIFICATION .......................................................20

FIGURE 1-8: JACKING LOCATION ........................................................................................................20

FIGURE 1-9: FLOAT SECURING LOCATIONS .....................................................................................21

FIGURE 1-10: FLOAT SECURING LOCATIONS OVERVIEW ..............................................................22

FIGURE 3-1 NOSE WHEEL & BOX.........................................................................................................29

FIGURE 3-2 NOSE WHEEL GREASING................................................................................................31

FIGURE 3-3 NOSE GEAR ITEMS...........................................................................................................33

FIGURE 4-1 MINIMUM BRAKE LINING THICKNESS...........................................................................37

FIGURE 4-2 MAIN GEAR, LOWER.........................................................................................................39

FIGURE 4-3 MAIN GEAR GREASING....................................................................................................41

FIGURE 4-4A MAIN GEAR ADJ. DOWN.................................................................................................42

FIGURE 4-4B MAIN GEAR ADJ. DOWN ................................................................................................43

FIGURE 4-5 MAIN GEAR ADJ. UP..........................................................................................................44

FIGURE 4-6 MAIN GEAR DOWN STOP ADJ.........................................................................................45

FIGURE 4-7 ROTARY ACTUATOR .........................................................................................................49

FIGURE 4-8 MAIN SHOCK STRUT.........................................................................................................50

FIGURE 5-1 HYDRAULIC SCHEMATIC .................................................................................................55

FIGURE 5-2 HYDRAULIC PLUMBING ...................................................................................................56

FIGURE 6-1 WATER RUDDER RETRACTION & EMERGENCY GEAR PUMP HANDLES...............60

FIGURE 6-2 WATER RUDDER CABLE ROUTING................................................................................61

FIGURE 9-1 FLOAT KIT INSTALLATION ITEMS...................................................................................77

FIGURE A-1 YAGI ANTENNAS INSTALLED ........................................................................................101

FIGURE A-2: CUFF REMOVAL..............................................................................................................101