3

External

dimension(LxWxH)

1450×680×

1480mm

2190×550×

1210mm

1125×620×

1680mm

2430×740×1780mm

Net weight 100kg 110kg 60kg 120kg

Note: Since 2006, we have changed the name of model FR-1100 into model FR-1120, with their spare parts

and worn parts universal.

IV.Performance Features

1. Two series derivate from FR-1120 series: one is FRM-1120 series, among this series, both

vertical sealer and horizontal sealer are equipped with solid-ink roller coding mechanism,

further, model FRS-1120W can also choose to be equipped with color ribbon printing

mechanism. The other is FR-1370 series, all of which belong to vertical sealer with two sets of

heating blocks, suit for sealing thick plastic bags.

The instructions concerning printing mechanism has nothing to do with the sealer without

printing mechanism. And model FRM-1370AL/M is a customized order, which is equipped

with two heating blocks and solid coding mechanism.

2 This sealer, adopting electronic thermostat control unit and stepless speed-adjusting

transmission mechanism (Transmission speed of FR-1370AL/M and FR-1370AL/L is

unadjustable), can seal various plastic film bags in different materials and can also be

equipped with varied packaging production lines. The machine has no limitation on sealing

length, which is characterized by high efficiency in continuous sealing, reliable sealing quality,

rational structure and convenient operation etc.

3. FRM-1120 series can use solid-ink roller to print desired colored label while sealing, with the

characteristics of high definition, instant print and instant dry and strong adhesion; For letters

in R type arrange, the machine can print two lines in font size two (18PT) and three lines in

font size five (10.5PT), and 20 types can be arranged in each line. Special order for T arrange

or multi-line types is available.

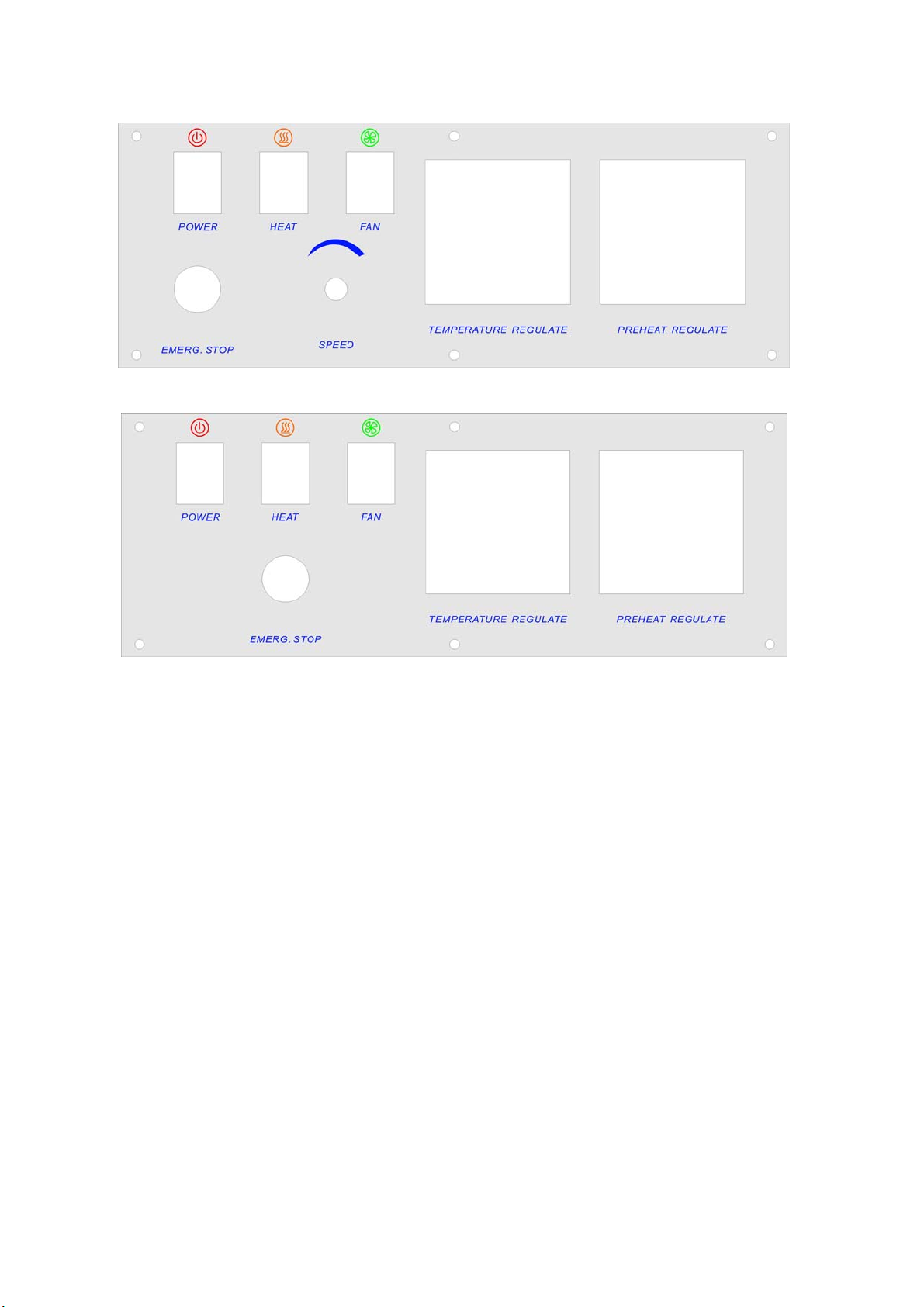

V.Structure & Working principle

1.This machine is made up of rack, speed-adjusting mechanism, sealing temperature

control system, transmission and conveying system, and printing assembly etc..(see

diagram 1~diagram 8)

2.After the power supply being connected, electrothermal elements produce heat that

rapidly raise the temperature of both upper and lower heat blocks. And use the

temperature controller and speed-adjusting mechanism to adjust the temperature that

needed, the plastic packing bag is transmitted by conveyor belt, and its sealing part will

be conveyed into the middle of two working sealing belts, then it is clamped by the two

sealing belt and conveyed into the heating area, sealing part is pressed by two heating

blocks and impressing wheels there, which could make the plastic film fuse and stick

together. After this, the sealing part will be conveyed into the cooling area for cooling,

and then to be pressed by embossing wheel for making stripe or netted pattern, at last,

colored label on the sealing part will be coded by printing wheel.

3.The transmission of sealing and printing is started by motor, which drives sealing belts,

guiding belts and conveyor belt to work synchronously, as well as make printing