2

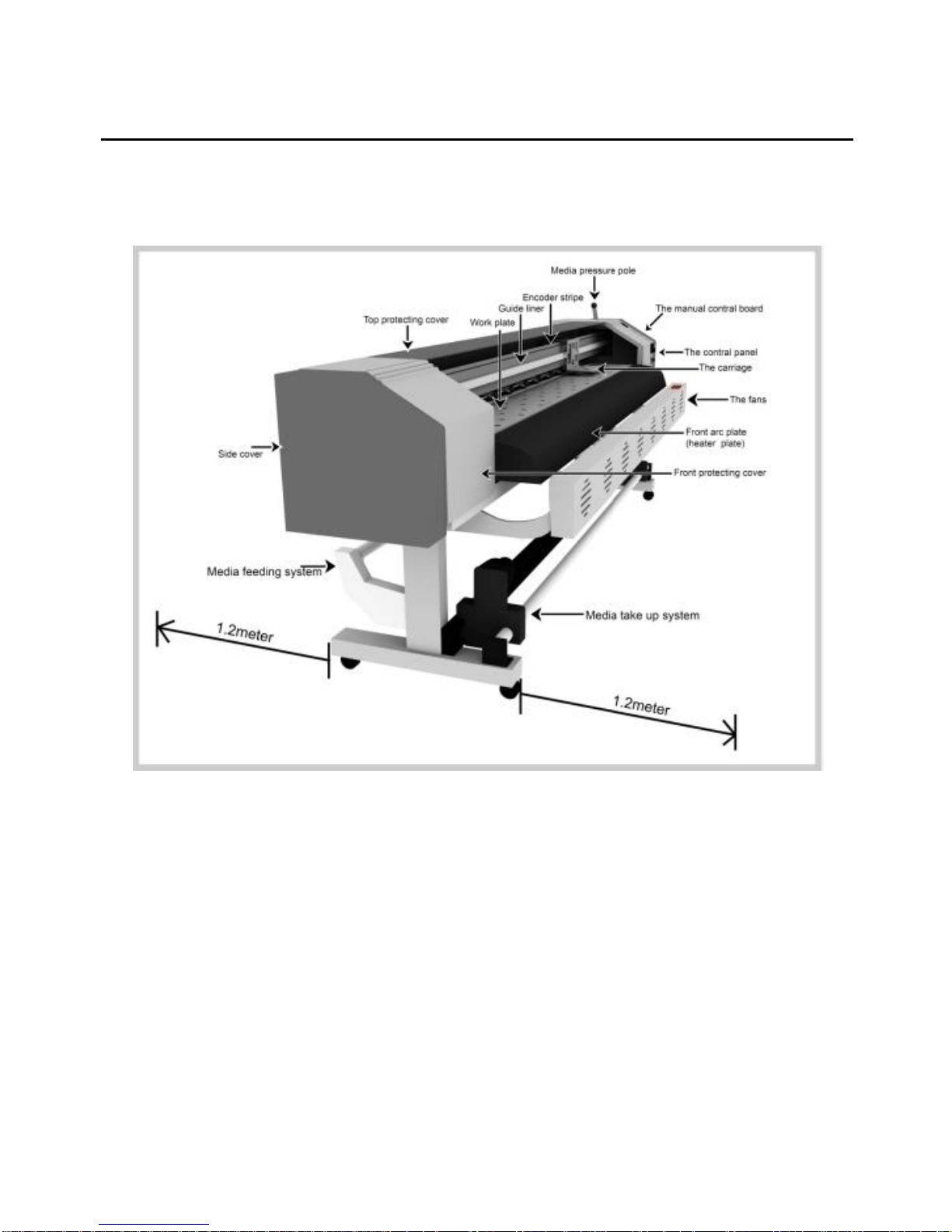

We’d like to express our sincere congratulations on your having a high capability

eco-solvent printer——Ultra 9600 1602S, and also appreciation for your support to

WIT-COLOR products. Please read this manual carefully,which can help you to solve the

problems encountered in the course. The table of contents can help you find the relevant

section needed.

Attention

WIT-COLOR is the trademark of Shanghai Wit-Color Digital Science &

Technology Co., Ltd. Wit-Color has the copyright of Ultra 1000,Ultra 2000, Ultra 3000,

Ultra 4000, Ultra 9000, Ultra 9100 ,Ultra 9200 solvent printer and eco-solvent printer,

including every spare parts, boards and software. Any copy by company or individual is

not allowed. Without authorization, this manual shall not be reprinted or propagated.

Ultra 9600 series printer has passed 3Q Conformity ofQuality Management System

Certification and ISO9001 Quality Certification. Ultra 9600 series printer is up to the

standard of printing equipment. Please pay attention to the following working

environment when you use the printer.

1. Please keep the printer away from electromagnetism environment: television,

high speed electric machine, high voltage cable, mobile phone, radio etc. These

equipments will produce magnetic interference.

2. Please keep the room temperature between 10 and 40 Celsius degree while printer

is working. Too high or too low temperature will reduce the printer’s using life and affect

the quality of the image.

3. The room should be in smooth ground with ground wire connection.

4. Please avoid direct sunlight and keep printer in ventilation and favorable

humidity.

5. Please keep the room clean, and avoid operating the machine under dust.

Displacement is inevitable during transportation. In this case, the engineer will

adjust it. You can not return or ask for compensation according to this issue.

Within the warranty time, WIT-COLOR provides maintenance and technical support

except the damage caused by human, bilging and thunderstrike. Please read the manual

carefully. Any question, please contact WIT-COLOR after-sales service department for

support.

Please don’t dismantle the printer privately. When the printer is in high-speed

operation, please pay attention to the safety symbols to avoid unnecessary injury. Out of