V.. / NV.. / CV..

Revision: 05 2022-D059517 en-1

Table of Contents

1 About this manual ................................................................................................3

1.1 Information symbols and cross references ..........................................................3

1.2 Scope of delivery .................................................................................................3

2 Safety.....................................................................................................................4

2.1 EC/EU Directive ...................................................................................................4

2.1.1 Machinery Directive.........................................................................................4

2.2 Personnel.............................................................................................................4

2.3 Intended use ........................................................................................................4

2.4 Reasonably foreseeable misuse..........................................................................5

2.5 General safety instructions ..................................................................................5

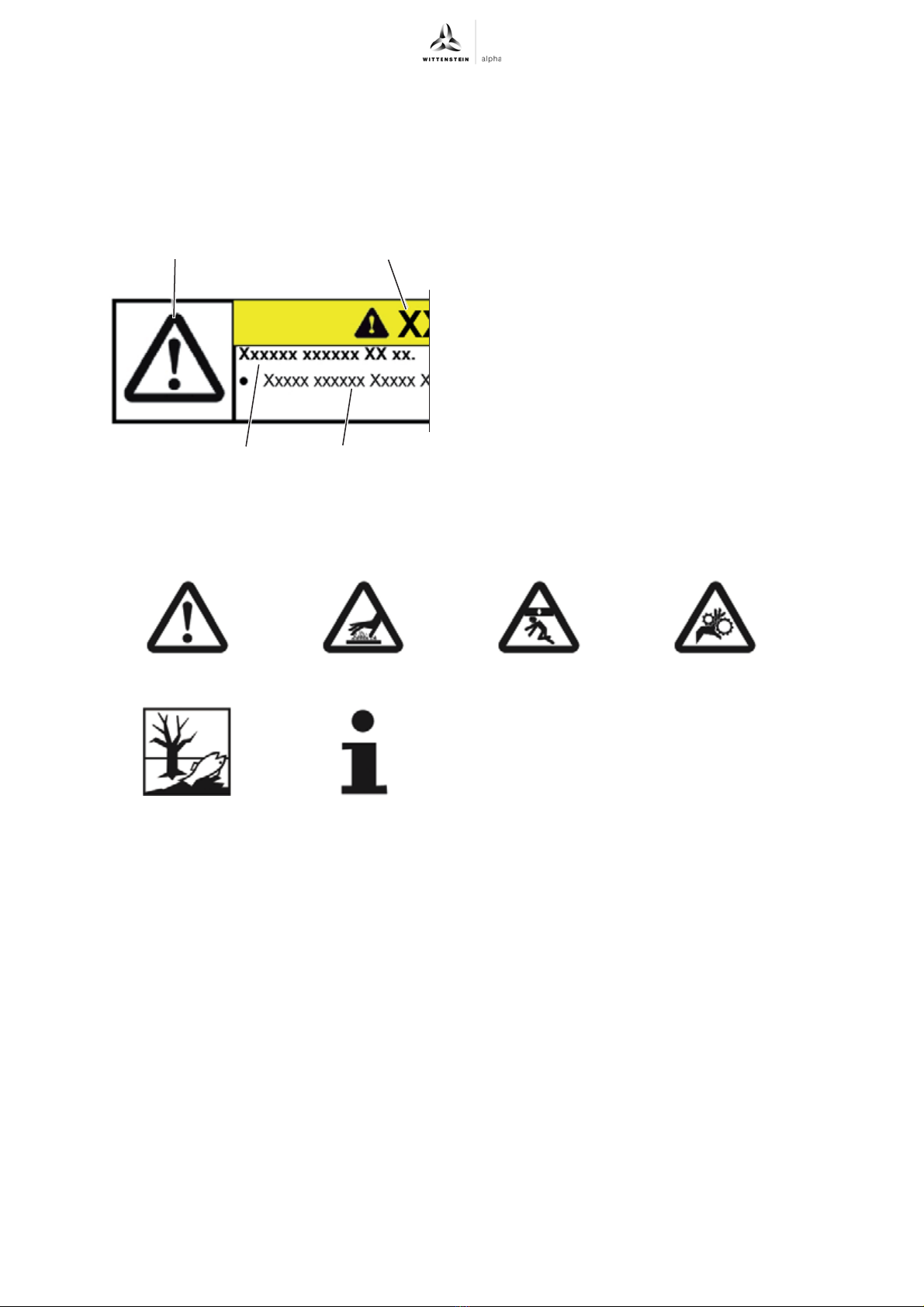

2.6 Structure of warning instructions..........................................................................6

2.6.1 Safety symbols ................................................................................................6

2.6.2 Signal words....................................................................................................7

3 Description of the gearbox..................................................................................8

3.1 Overview of gearbox components .......................................................................8

3.1.1 Version with through-holes..............................................................................8

3.1.2 Version with threaded bores............................................................................8

3.2 Name plate...........................................................................................................9

3.3 Ordering code ......................................................................................................9

3.4 Dimensions and performance data ....................................................................10

3.5 Information about the lubricant ..........................................................................10

3.6 Notes regarding the IP protection class .............................................................10

4 Transport and storage .......................................................................................11

4.1 Packaging ..........................................................................................................11

4.2 Transport............................................................................................................11

4.2.1 Transport of gearboxes up to size 063..........................................................11

4.2.2 Transport of gearboxes size 080 and up.......................................................12

4.3 Storage ..............................................................................................................12

5 Assembly ............................................................................................................13

5.1 Preparations.......................................................................................................13

5.2 Mounting the motor to the gearbox ....................................................................14

5.3 Mounting the gearbox on a machine..................................................................16

5.3.1 Mounting with through-holes .........................................................................16

5.3.2 Mounting with slotted holes ..........................................................................17

5.3.3 Mounting with threaded bores .......................................................................18

5.4 Components mounted to the output side ...........................................................18

5.4.1 Mounting with shrink disk ..............................................................................19

6 Startup and operation ........................................................................................20

7 Maintenance and disposal.................................................................................21

7.1 Maintenance schedule .......................................................................................21

7.2 Maintenance work..............................................................................................21

7.2.1 Visual inspection ...........................................................................................21

7.2.2 Checking the tightening torques....................................................................21

7.3 Startup after maintenance work .........................................................................21

7.4 Disposal .............................................................................................................21