4

www.wittur.com

© WITTUR • All rights reserved

PM.2.004921.EN - 808-001-000 SDS©rel 3 · Edition 22 July 2020

Drive - Instruction Manual

6�7�2 Gong While Opening ������������������������������������������������������������������������������������������������������������������ 26

6�7�3 Thermic alarm signal������������������������������������������������������������������������������������������������������������������ 26

6.8 Forced Closing (Nudging).................................................................................................................................................................. 26

6.9 Fire Fighting (Param. Code 19)......................................................................................................................................................... 26

6.10 Double TB................................................................................................................................................................................................ 26

6.11 E.O.D. (Emergency Opening Device) and timeout (Param. Code 20).................................................................................... 27

6.12 Protective Device Logic Kn (Param. Code 21).............................................................................................................................. 27

6.13 Motor Rotation during closing (Param. Code 22)....................................................................................................................... 27

6.14 Motor type (param. code 90)............................................................................................................................................................. 27

6.15 Closing parking mode (Param. Code 25)....................................................................................................................................... 27

6�15�1 Closed skate parking (default) ���������������������������������������������������������������������������������������������������� 27

6�15�2 Opened skate parking ��������������������������������������������������������������������������������������������������������������� 27

6�15�3 PM activation Delay (Default 300 sec�)����������������������������������������������������������������������������������������� 27

6�15�4 PM Opening space (Default 90 mm)�������������������������������������������������������������������������������������������� 27

6�15�5 PM position error (Default 5 mm)������������������������������������������������������������������������������������������������ 27

6�15�6 PM position control (Default 00)�������������������������������������������������������������������������������������������������� 28

6.16 Skate type (Param. Code 26) ............................................................................................................................................................. 28

6.17 AUX Input (Param. Code 32).............................................................................................................................................................. 28

6�17�1 Disabled (default) ���������������������������������������������������������������������������������������������������������������������� 28

6�17�2 % Partial Reopening ������������������������������������������������������������������������������������������������������������������ 28

6.18 IM (reversing motion) signal type (Param. Code 34) ................................................................................................................ 29

6�18�1 Im pulse� ��������������������������������������������������������������������������������������������������������������������������������� 29

6�18�2 IM Continuous (default) ������������������������������������������������������������������������������������������������������������� 29

6�18�3 Monostable pulse� ��������������������������������������������������������������������������������������������������������������������� 29

6.19 KB Options (Param. Code 27)............................................................................................................................................................ 29

6.19.1 Rev.SenseO(Default)������������������������������������������������������������������������������������������������������������� 29

6�19�2 Rev� Sense On ��������������������������������������������������������������������������������������������������������������������������� 29

7 Trial operations before start up the door controller������������������������������������������������������������������������������������ 31

7.1 Self-learning cycle................................................................................................................................................................................ 31

7.2 Self-learning cycle with the door controller only (without using the handset).............................................................. 31

8 Instruction with handset�������������������������������������������������������������������������������������������������������������������������� 32

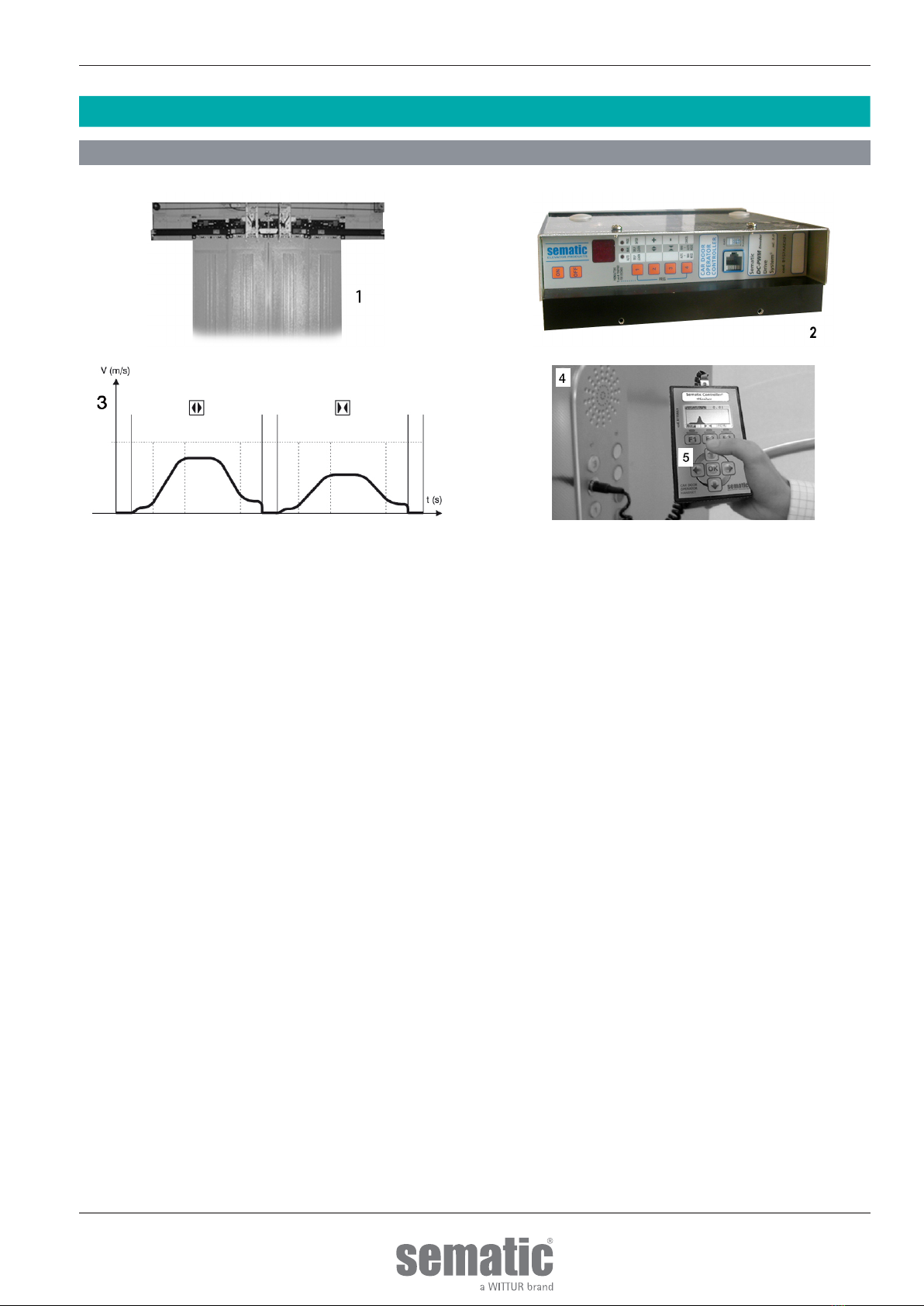

8.1 Handset (optional) ................................................................................................................................................................................32

8.2 User Handset menus and submenus..............................................................................................................................................33

8.3 Self-learning cycle activation by means of the handset......................................................................................................... 34

8.4 Reversing System Force setting by means of the handset .................................................................................................... 34

8.5 Option “Reset speed profile” ............................................................................................................................................................. 34

8.6 Option “Advanced Settings”.............................................................................................................................................................. 34

8�6�1 Option “Parameters” ������������������������������������������������������������������������������������������������������������������ 35

8�6�2 Option “MLC Parameters” ����������������������������������������������������������������������������������������������������������� 36

8�6�3 Option “Inputs Parameters” �������������������������������������������������������������������������������������������������������� 36