3

CABINETRY 3

We are confident that you will be pleased with your purchase of Wolf Designer Cabinets. As an educated

consumer, you need to know the characteristics of the wood used in the finished cabinets you have purchased.

SPECIES AND FINISH

Cherry is a rich and multi-colored hardwood distinguished by its owing grain pattern. Color varies from light to deep

reddish brown and will darken or mellow with age. This will be more noticeable with natural or light stain finishes. This

dramatic color change will occur with exposure to light and usually takes place within the first six months. Mineral

streaks, pitch pockets, pin knots and sapwood all occur naturally in cherry and are acceptable characteristics and

not considered warranty defects.

Hickory is known for its strength, open grain and distinctive color variation within each piece of wood. Ranging from light

to deep brown, hickory’s unpredictable color spread is especially noticeable in a natural or light finish, with darker stains

mellowing the variation. The color variation, small pin holes and knots are naturally occurring, and Rustic Hickory

incorporates larger sporadic knots and pin holes. These characteristics are acceptable and not considered warranty defects.

Maple offers a smooth, closed grain pattern, generally off-white in color with varying tones of light pink and yellow-

brown. Maple contains a natural resin that causes the wood to turn amber as it ages. This will be more noticeable

with light stain finishes and is accelerated by exposure to natural light. Other natural occurring characteristics include

small, light tan or dark mineral streaks (up to 1/4" x 2" acceptable) that form when trees absorb minerals from the soil.

Oak (Red) is characterized by its wide, open grain patterns and extreme durability. Variations in grain pattern and

color, small knots and pin holes are attributes of nature, giving oak its distinctive beauty. Naturally occurring color

variation includes light tan and pink to medium brown and dark red with occasional green, yellow and black mineral

streaks. These characteristics are more prominent in natural and lighter stain finishes.

Rustic Alder has a ne, straight-grain pattern and even texture. The color is a light brown with a reddish tinge that

stains evenly. Rustic Alder includes character spots, knots, burls and blemishes, which do not affect the product

durability. As one of the softest hardwoods, alder can be easily dented or scratched. These characteristics are not

considered warranty defects.

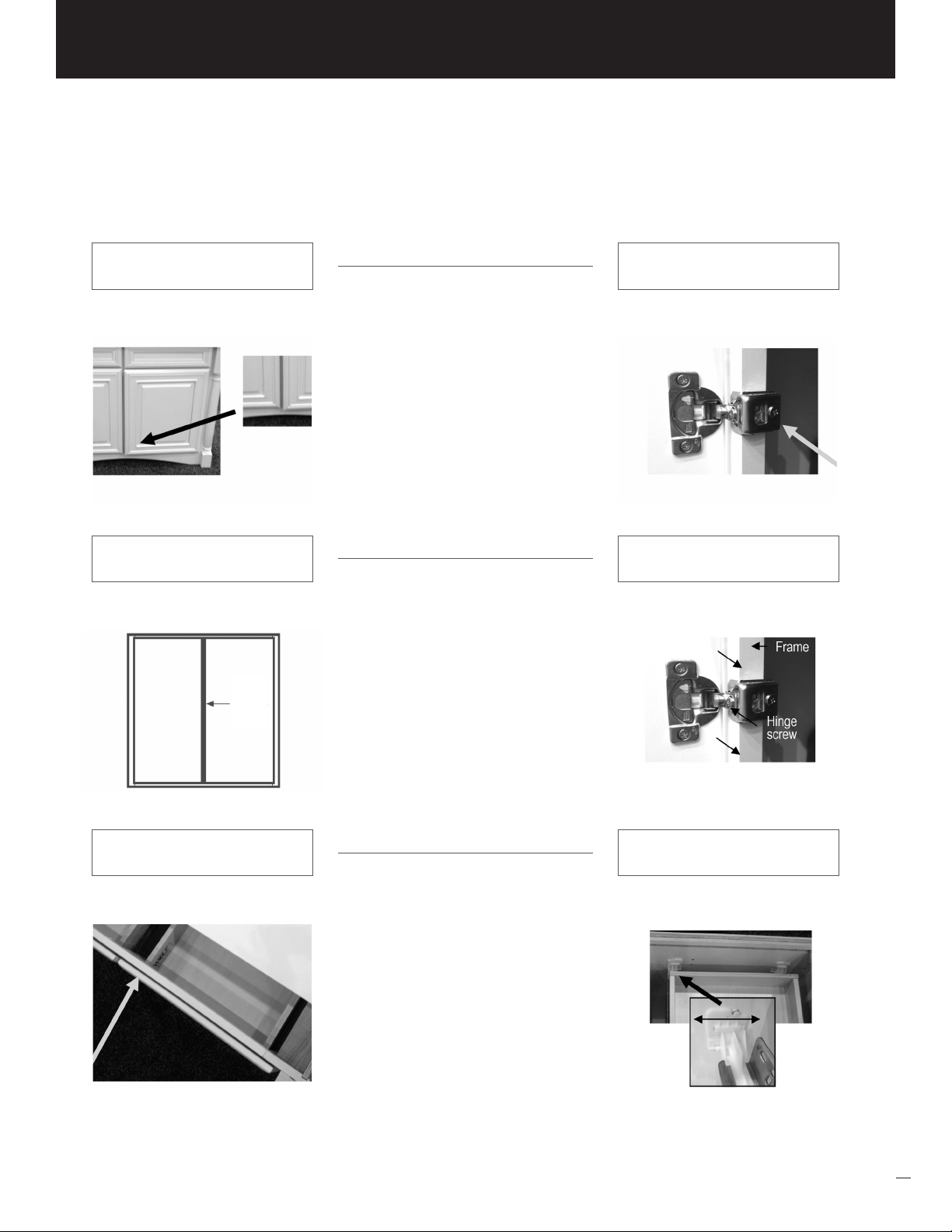

Thermofoil doors and drawer fronts are constructed from a single piece of medium-density berboard (MDF) and

covered with a durable thermofoil laminate. The wood face frame is painted with a furniture-quality nish to closely

match the laminate. You may notice some small seams in the paint at the joints of the cabinetry face frame due to

expansion and contraction of the wood. This will not affect the integrity of the cabinet or the finish. Thermofoil cabinets

should not be placed adjacent to a high heat appliance; we suggest using a filler next to the heat source.

GLAZING PROCESS

The glazing process adds an additional contrasting color to the product to give an aged, worn and antique

appearance. Glazing will range from an even appearance to varied coverage due to the hand application and

variation in how the glaze color hangs up in the profiles of the product. The final appearance of each glaze piece will

depend upon door design, edge profile, wood characteristics and base stain color.

Glazing over Stain

The contrasting glaze will also darken the shade of the underlying stain color. Doors, drawer fronts and large

mouldings are hand glazed:

• This hand application allows for an “artisan” finish, meaning no two doors or drawers will look exactly the same.

The amount of hang-up will vary on each door.

• In areas with deep edges, corners or unique wood characteristics, a heavier amount of glaze may collect and

remain as removal will be more difficult.

• Flat and smooth areas are easier to wipe, resulting in less hang-up on the surface.

Face frames, veneer end and back panels and small mouldings get an applied glaze so that these parts match

the doors and drawer fronts.

STAIN CHARACTERISTICS & VARIATIONS