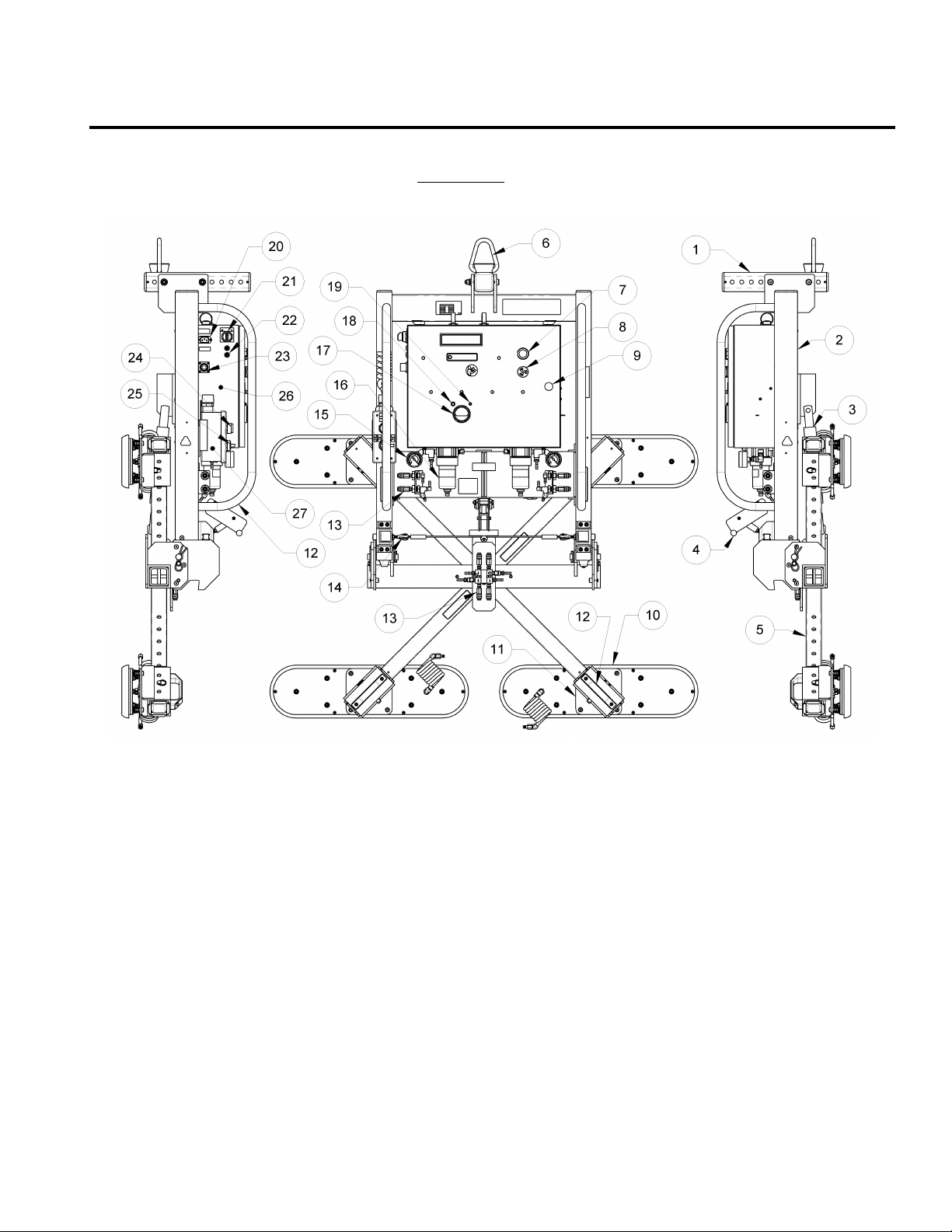

Rev 0.0/9-10 CLADDING LIFTER ● W/VIFS625 PAD INSERTS #35078:

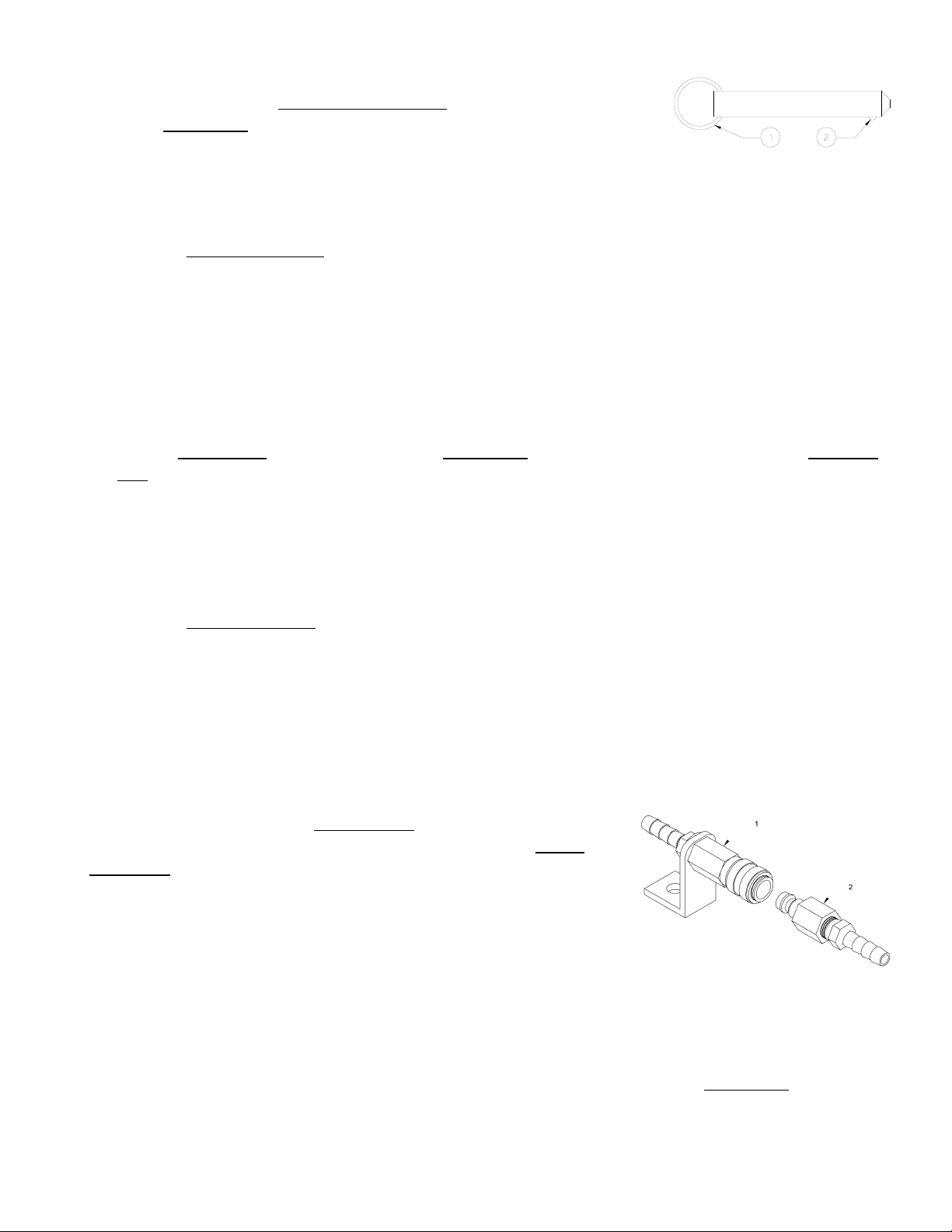

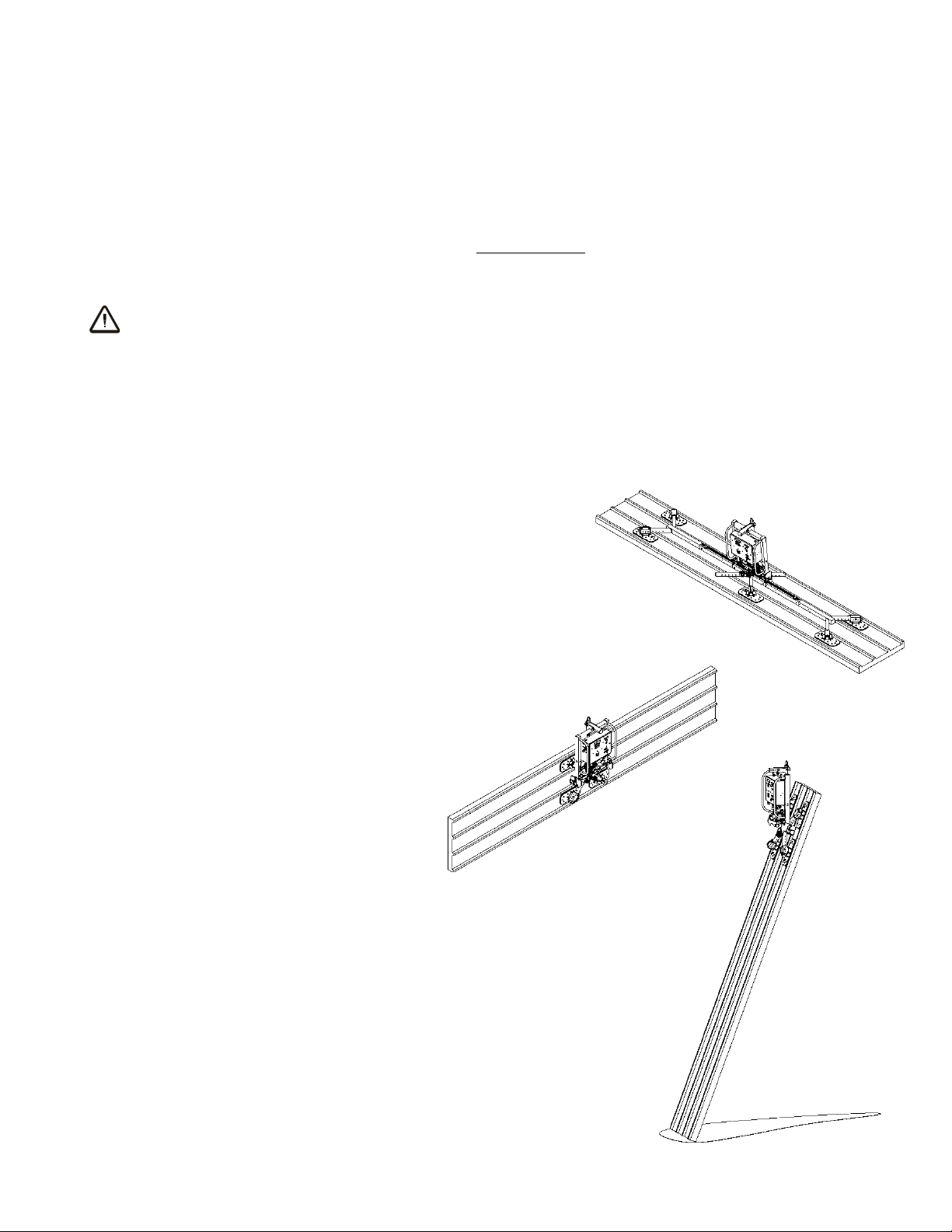

To Install/Remove Pad Frame Extensions

1) Insert the end of a pad frame extension in one socket on the

main pad frame, so that the holes align for the cotterless hitch

pin.

2) Secure the pad frame extension in the pad frame by pushing a

cotterless hitch pin through the holes until the retaining ball

emerges on the far side of the pad frame socket.

3) Use the quick connectors to connect the vacuum hoses from the pad frame extensions to the

main pad frame as directed in the discussion to follow.

3) Repeat steps 1-3 to install the other pad frame extensions as required for the pad frame

configuration desired.

4) To remove the pad frame extensions, reverse this procedure. Store pad frame extensions in

a clean, dry location to protect them from environmental exposure.

To Install/Remove, Rotate and Position Pad Mounts

1) Slide a pad mount over one arm of the pad frame. Note that the orientation of the vacuum

pad can be changed by moving the pad mount to an arm angled in a different direction. This

can be useful in avoiding obstacles or features on the load. Each pad mount can also be

rotated 180° to allow for the best hose routing.

2) Position the pad mount approximately in the desired position and line up one of the locating

holes in the pad mount with a corresponding hole in the pad frame arm. Multiple holes are

provided to accommodate small increments between mounting locations.

3) Use the quick connector to connect the vacuum hose from the vacuum pad to the appropriate

circuit of the vacuum system as directed in the discussion to follow.

4) Repeat steps 1-3 to install and position each vacuum pad as required for the pad frame

configuration desired.

5) To remove the pad mounts, reverse this procedure. Store pad mounts in a clean, dry location

to protect them from environmental exposure.

To Connect/Disconnect Vacuum Hoses

The vacuum hose for each vacuum pad is connected to or

disconnected from the vacuum system by means of a quick

connector. To connect the vacuum hose, push the male and

female ends of the connector together until they lock. To

disconnect the vacuum hose, move the release ring on the

female end away from the male end until the connector

separates.

Note: For proper function of the dual vacuum system, make sure

that vacuum pads are connected to alternating circuits of the

vacuum system (red or green).

Note: Whenever a quick connector is disconnected, the corresponding vacuum pad does not

contribute to the load capacity, whether or not the pad is mounted on the pad frame.

COTTERLESS HITCH PIN

1 PULL RING

2 RETAINING BALL

QUICK CONNECTOR

1) FEMALE END

2) MALE END