Remote Operation

Cold Weather Operation

Remote Operation ROdoc121516 1-7

1

1.4 Cold Weather Operation

If the sawmill is operated or stored in freezing conditions, the cable chain may freeze.

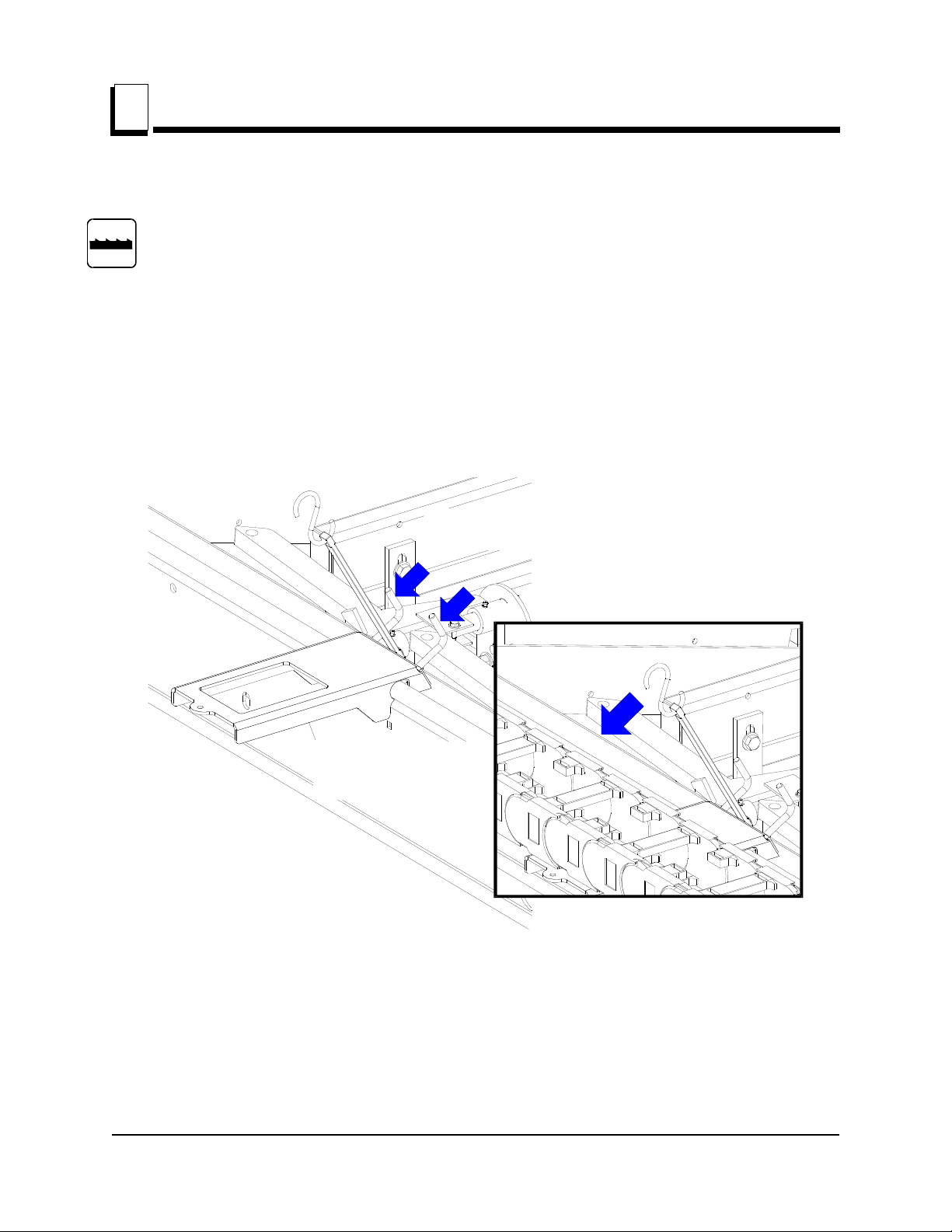

Before moving the saw carriage, check to see if the chain is frozen:

1. Remove the chain support bracket (See Section 1.1).

2. Pull the chain up at a few locations to determine if it moves freely. If you detect the chain

is frozen, proceed to the recommended deicing procedure below.

3. If the chain seems to move freely by hand, use the power feed to slowly move the saw

carriage toward the rear of the mill. Since the saw carriage returns only at full speed,

moving the saw carriage forward will allow you to slowly engage the cable chain to be

sure it is not frozen. If you detect the chain is frozen, proceed to the recommended

deicing procedure below.

Recommended Cable Chain deicing Procedure

To de-ice the chain, apply a salt solution (preferably calcium chloride and water) to the

entire length of the chain. Allow the solution to sit until the chain can move freely. The

strength of the solution and time required to free the chain will depend on how cold the

weather is and how much ice has accumulated in the chain.

Before storing the sawmill after using the salt solution, be sure to rinse the salt from any

metal portions of the sawmill frame to prevent corrosion. Refer to the recommended

cold-weather storage procedure below to prevent the chain from freezing.

Recommended Cable Chain Ice Prevention Procedure

Before storing the sawmill in freezing temperatures, apply a 50/50 solution of

environmentally safe antifreeze (Sierra) and water to the cable chain. A garden sprayer

can be used to apply the solution.