2

Your Kiln

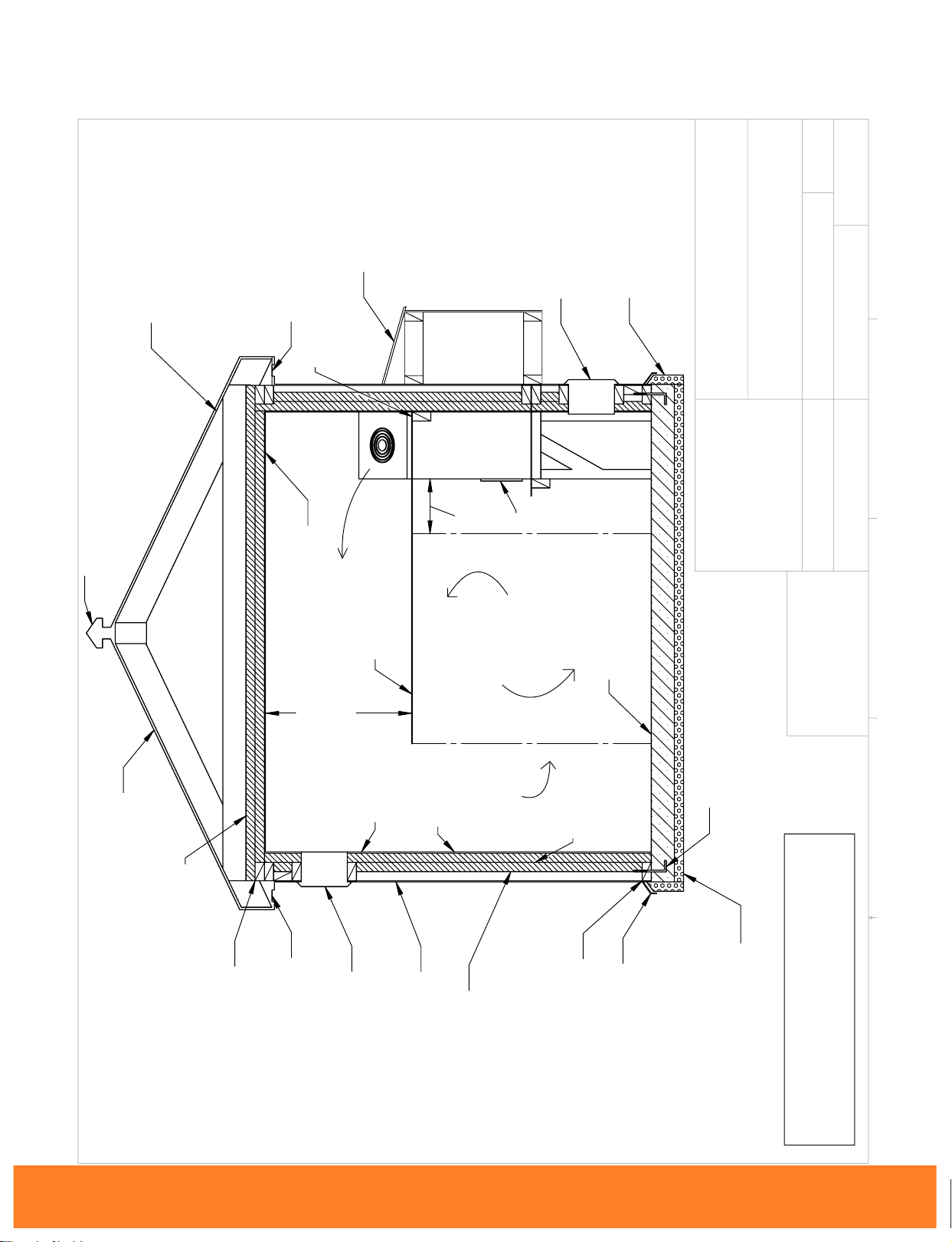

How your Dehumidification Kiln Works

Thank you for purchasing a Wood-Mizer

Dehumidification Kiln and taking the first step

towards making the lumber industry cleaner and

more efficient! Years of development, innovation

and the highest quality materials have gone into

building your kiln. It’s our dedication to efficiency

that sets Wood-Mizer kilns apart from the rest

making your system the best on the market.

During kiln drying, moisture from green lumber is

evaporated into the air increasing the humidity inside

the chamber. The lumber can’t continue to dry if the

air becomes over-saturated therefore the moisture

must be periodically removed from the chamber.

In a conventional kiln moisture would be expelled

through venting. Venting causes a signicant loss

of heat resulting in a waste of energy to bring the

kiln back up to temperature.

Instead of venting,Dehumidification Kilns

utilize a refrigeration system that condenses

the excess moisture. This moisture is then

drained off retaining the existing heat energy. After

the moisture is removed and heat is reintroduced to

the dry air it is pumped back into the kiln

chamber to start the process over. Unlike

conventional kilns the heater in your kiln is only

used during the initial warm up and sometimes

when temperature increases are desired during the

cycle, saving you time and money. But that’s not all

your new kiln has to offer!

Though Wood-Mizer kilns don’t rely on venting

to get rid of moisture, a Vent System is supplied

to add extra control of your kiln temperature. If

the internal kiln temperature exceeds what’s

required, these vents can be opened to remove

excess heat and bring the temperature back to

where it needs to be.

Finally Wood-Mizer offers a wide variety of upgrades

and accessories to enhance your kiln drying experience.

See the upgrades and accessories section on page

34 for more information. By purchasing a Kiln you

have the support of the service team, the very

same professionals that built and tested your

unit. Enjoy your new system!

Getting Started

Please read through carefully as some options may not

apply.

Floors

Concrete floors with insulation installed underneath

is recommended for best results. However if

the kiln is going to be on an existing concrete

floor, the insulation may be omitted. Concrete must

not extend beyond the kiln walls.

Wood floors may be used but must be built

to construction guidelines (see Pg 3)

Ceilings

If the kiln chamber is a freestanding outside building,

the attic space must be well ventilated through

the eaves. This is done to avoid any moisture

buildup in this space, which will condense on the

cold roof and drip onto the insulation.

An interior kiln can have the ceiling insulation

open to the atmosphere.

Ceilings must be built to construction

guidelines. (Pg 3)

Doors

At the front of the kiln chamber install bay/

loading doors with at least two sides hinges and

a center door latch to close (recommended). Top

hinged or a lift off doors are also acceptable.

At least one access door should be installed in

the back of the chamber to allow for service of

the dehumidifier and/or lumber monitoring.

All installed doors must:

•Be built to construction guidelines. However

they may be lightened by increasing the stud

spacing and using 3/8” plywood. The lighter

weight will reduce the load on the hinges

• Have a vapor barrier.

•Have gaskets wherever the door meets the kiln;

this will give a good, airtight t.

•Have a scraper type weather strip to reduce air

leakage if door sill is not present.