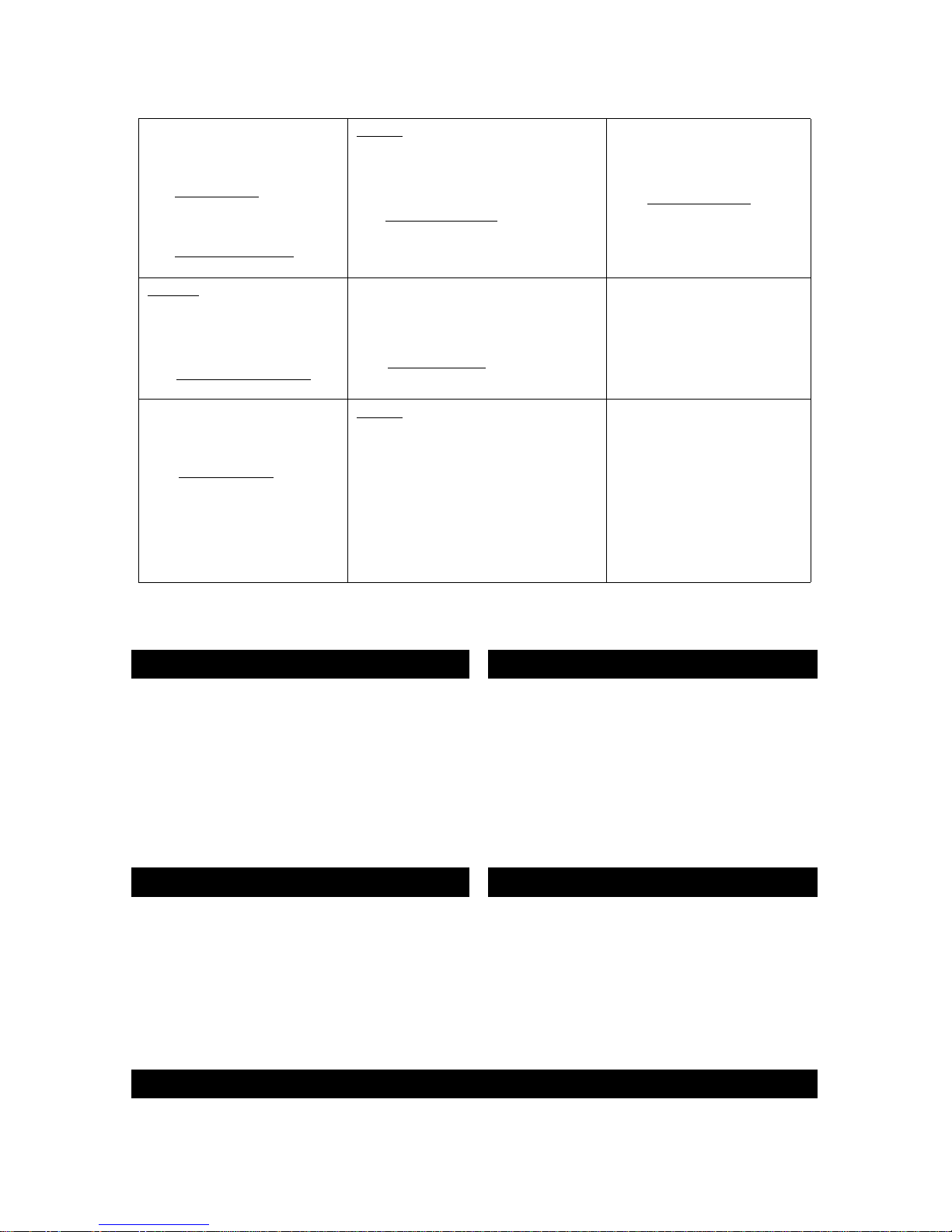

Table of Contents Section-Page

Table of Contents SW-07doc0227153

7.2 Multirip Edger Specifications.................................................................7-3

7.3 Dust Extractor Specifications.................................................................7-5

SECTION 8 ELECTRICAL INFORMATION (CE ONLY) 8-1

8.1 Electrical Diagram EG300EB_S (230V 50/60 Hz) ..............................8-2

8.2 Electrical Diagram EG300EB (230V 50/60 Hz) ..................................8-3

8.3 Electrical Diagram EG300EC (460V 50/60 Hz) ..................................8-4

8.4 Electrical Diagram EG300EH (400V 50/60 Hz) .................................8-5

8.5 Electrical Diagram EG300EH_S (400V 50/60 Hz) ..............................8-6

8.6 Electrical Component List, EG300EB_S (230V 50/60 Hz)...................8-7

8.7 Electrical Component List, EG300EC (460V 50/60 Hz).......................8-8

8.8 Electrical Component List, EG300EH_S (400V 50/60 Hz)...................8-9

8.9 Electrical Diagram, EG250 (400V 50/60 Hz) - African Version........8-10

8.10 Electrical Diagram, EG250EC (400V 50/60 Hz) - Russian Version ..8-11

8.11 Electrical Diagram, EG250S (400V 50/60 Hz) - CE Version .............8-12

8.12 Electrical Component List, EG250 (400V 50/60 Hz) African Version8-13

8.13 Electrical Component List, EG250EC (400V 50/60 Hz) - Russian Version8-14

8.14 Electrical Component List, EG250S (400V 50/60 Hz) - CE Version..8-15

SECTION 9 ELECTRICAL INFORMATION (U.S. ONLY) 9-1

9.1 Electrical Diagram, EG300EC25U (U.S. Only).....................................9-1

9.2 Electrical Component List, , EG300EC25U (U.S. Only).......................9-6

SECTION 10 REPLACEMENT PARTS 10-1

10.1 How To Use The Parts List..................................................................10-1

10.1 Sample Assembly.................................................................................10-1

10.2 Main Shaft Assembly...........................................................................10-2

10.3 Spacer Mounting Kit (Optional)...........................................................10-4

10.4 Infeed Rollers Assembly ......................................................................10-5

10.5 Hold-Down Roller & Anti-Kickback Assembly (EG300)...................10-7

10.6 Anti-Kickback Fingers (EG250) ...................................................10-9

10.7 Blade Setting Assembly .....................................................................10-10

10.8 Laser Guide Assembly (EG300) ........................................................10-12

10.9 Motor Assembly.................................................................................10-15

10.10 Control Box (EG300 CE ONLY).......................................................10-17

10.11 Electric Box (EG250) ......................................................................10-19

10.12 Table (EG300)....................................................................................10-20

10.13 Table (Option for EG250 Edgers) ...................................................10-22

10.14 Board Guide Fence.............................................................................10-23

10.15 Covers.................................................................................................10-24

10.16 EG250 Edger Top Cover ..............................................................10-26

10.17 Manual Blade Setting Assembly (EG250) ....................................10-27

10.18 Sawdust Hopper (EG300 and EG250 CE Version)............................10-30